Adjustable lens grinding device according to lens centre and arc radius

A grinding device and lens technology, which is applied in the direction of grinding drive devices, grinding machines, optical surface grinding machines, etc., can solve the problems of insufficient precision, inability to directly adjust the distance of the center of the sphere, and increase production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

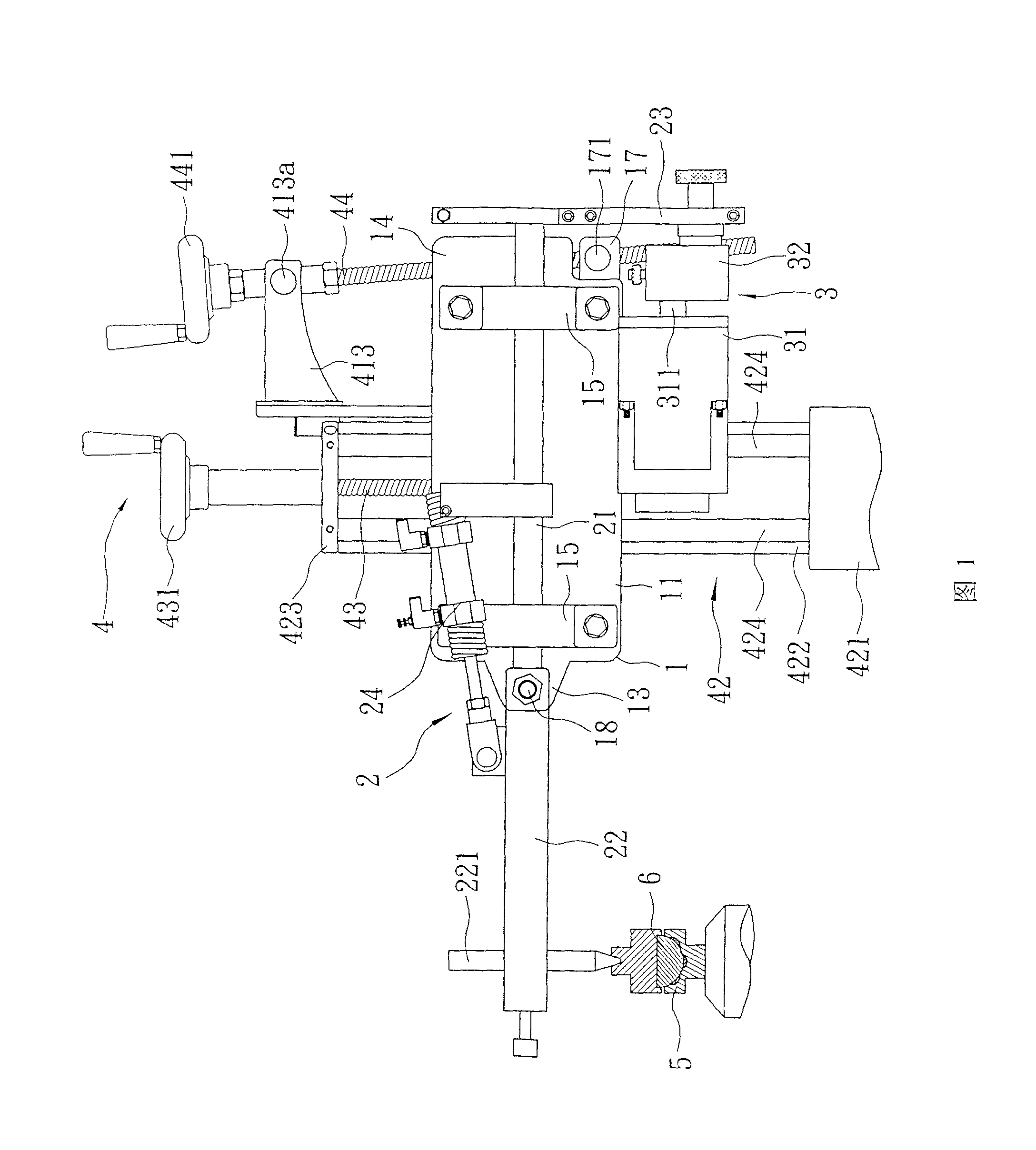

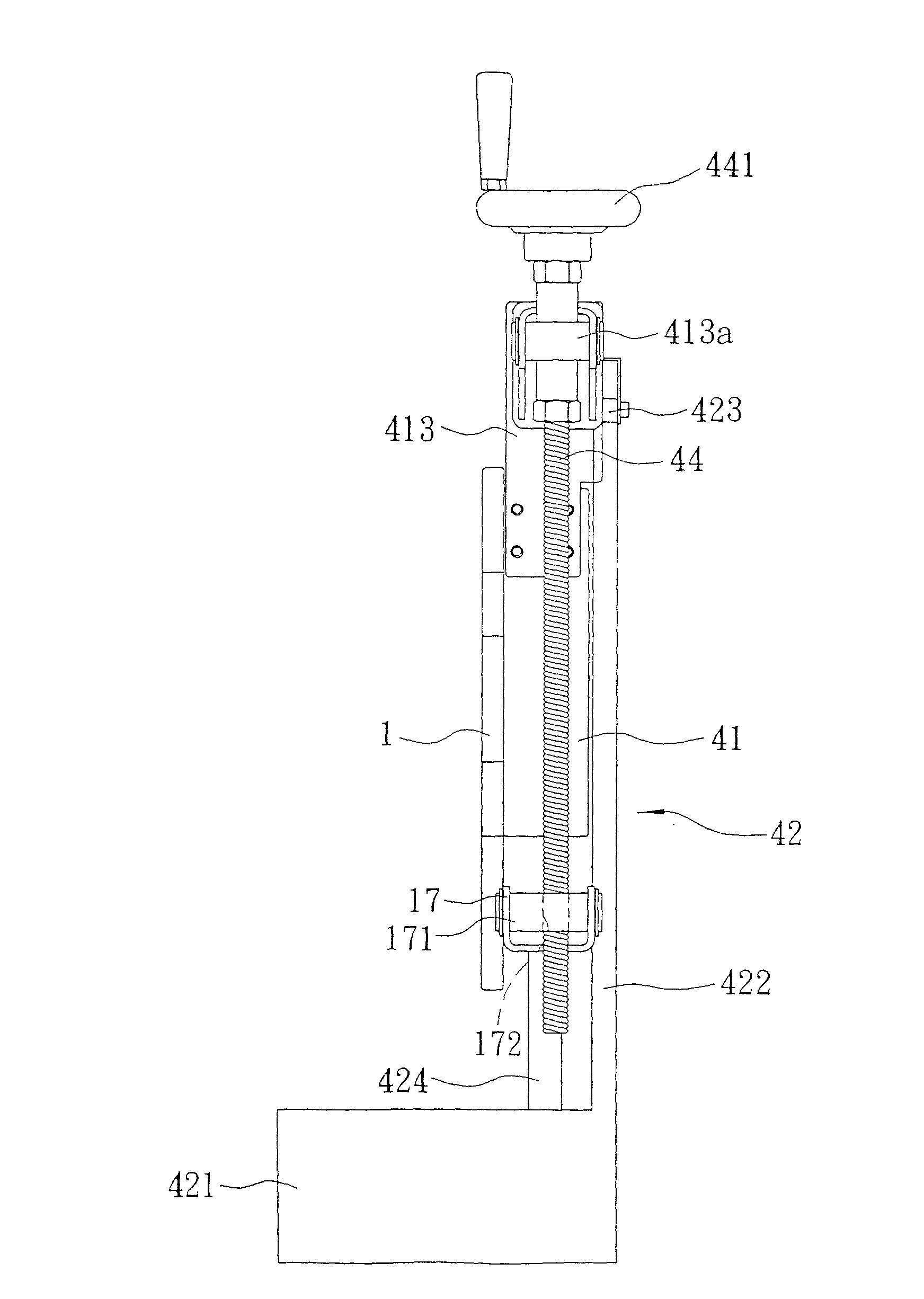

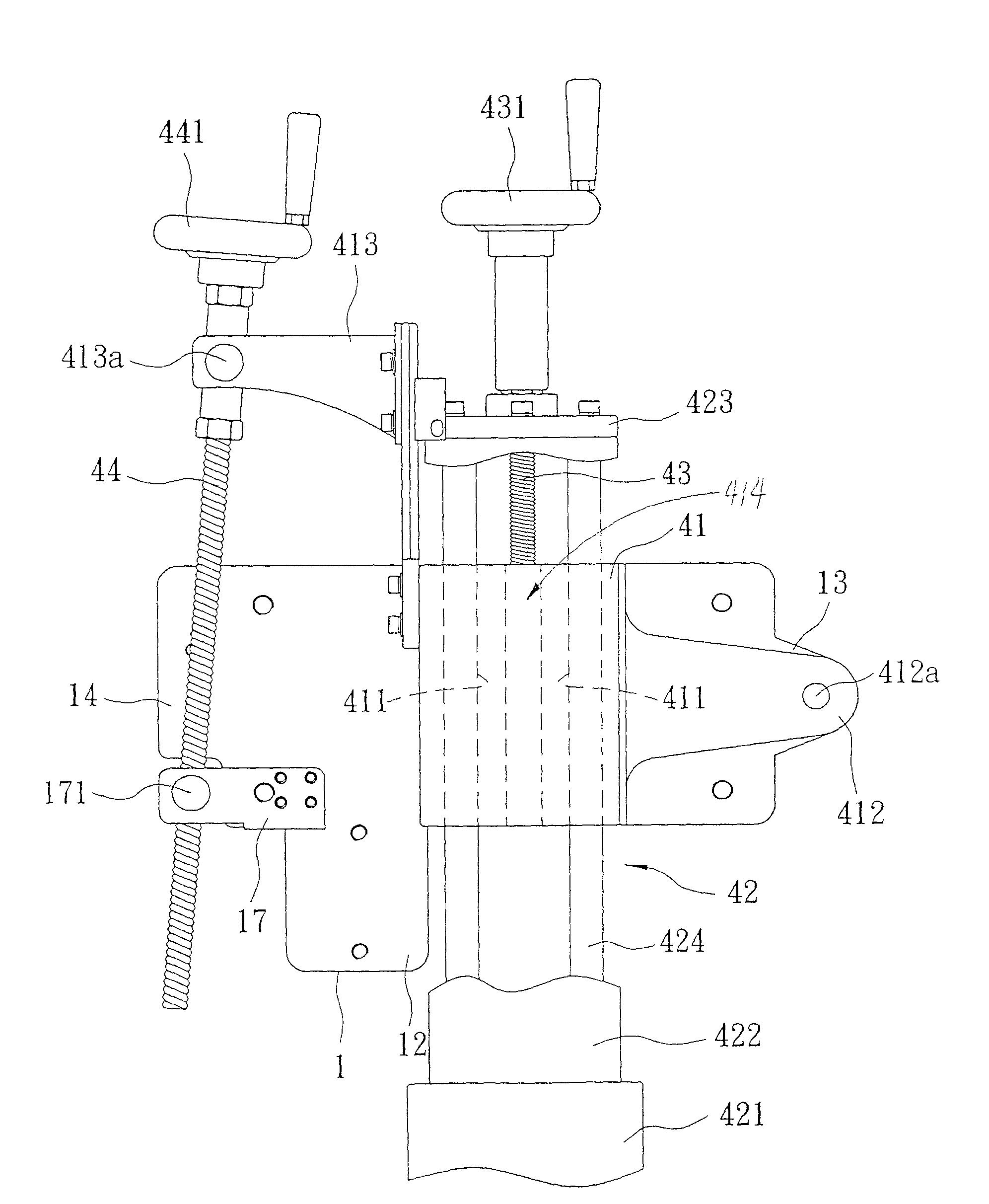

[0026] like Figures 1 to 4 As shown, this embodiment provides a lens grinding device that can be adjusted according to the lens spherical center and arc radius, which includes:

[0027] The upright substrate 1 has a first surface 11 , a second surface 12 , a first end 13 and a second end 14 . Two bearing seats 15 are correspondingly disposed on the first surface 11 between the first end 13 and the second end 14 . The first end 13 has a first pivot portion 16 , which is a pivot hole in this embodiment, and the second surface 12 has a coupling portion 17 at the second end 14 . In this embodiment, the coupling portion 17 is pivotally connected to the first rotating post 171 on the upright base plate 1 , and a first screw hole 172 is provided on the rotating post to pass through its radial direction.

[0028] The grinding mechanism 2 has a rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com