Extending-and-contracting drill bit grinding device

A technology of drill bit and grinding mechanism, which is applied to grinding drive device, grinding machine, grinding frame, etc., can solve the problems of troublesome operation, reduce the use time of grinding parts, increase the working time, etc., so as to avoid plate deformation and ensure the use of Longevity and guaranteed grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

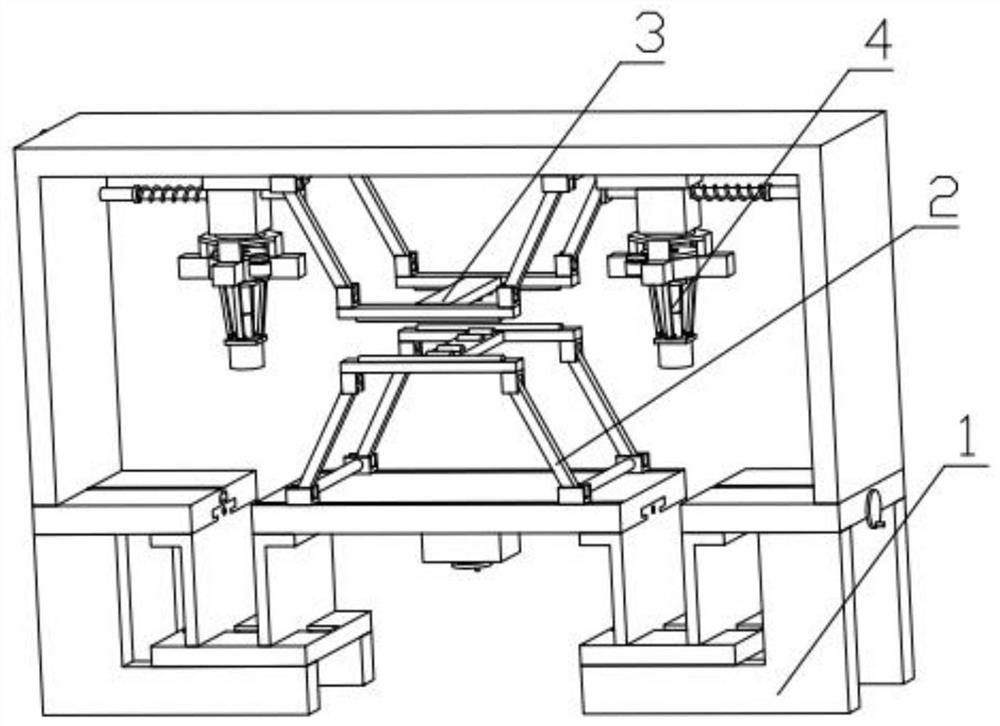

[0030] Combine below Figure 1-11 Describe this embodiment, a telescopic drill bit grinding device, including a vertical plate adjustment mechanism 1, a bottom adjustment mechanism 2, a top pressing mechanism 3 and an adjustment grinding mechanism 4, and the bottom adjustment mechanism 2 is fixedly installed on the vertical plate adjustment mechanism 1 , the top pressing mechanism 3 is fixedly installed on the vertical plate adjustment mechanism 1, and the adjustment grinding mechanism 4 is fixedly installed on the top pressing mechanism 3.

specific Embodiment approach 2

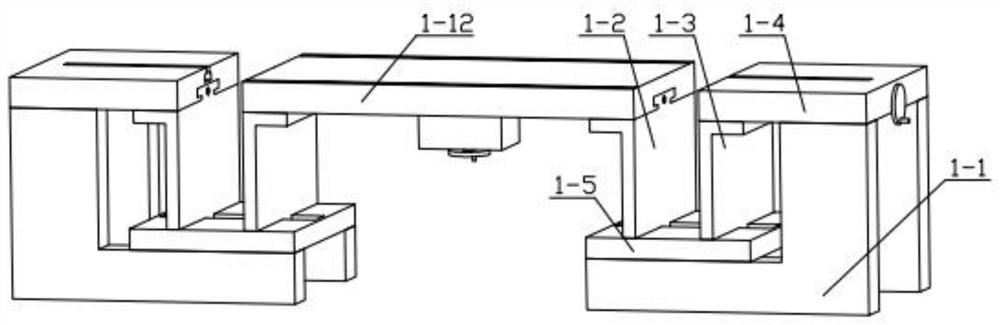

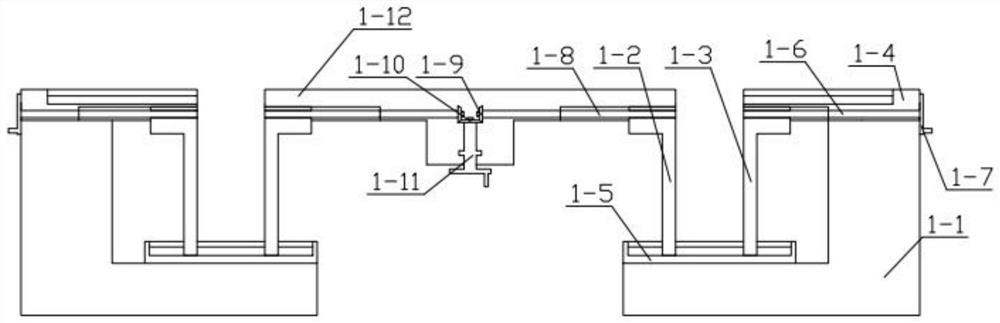

[0032] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain Embodiment 1, the described vertical board adjustment mechanism 1 includes L-shaped leg board 1-1, splint one 1-2, splint two 1-3, side top board 1-4, Bottom limiting plate 1-5, short threaded rod one 1-6, turntable 1-7, short threaded rod two 1-8, helical gear one 1-9, helical gear two 1-10, rotating rod 1-11, middle Top plate 1-12, the both sides of side top plate 1-4 are fixedly installed with L-shaped leg plate 1-1 respectively, and bottom limit plate 1-5 is fixedly installed on L-shaped leg plate 1-1, splint one 1-2 and The second splint 1-3 is all slidably installed in the groove provided on the bottom limit plate 1-5, and the other end of the splint two 1-3 is slidably installed in the groove provided at the bottom of the side top plate 1-4, and the splint one 1-4 The other end of 2 is slidingly installed in the groove provided at the bottom of the middle top plate 1-12, th...

specific Embodiment approach 3

[0034] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the bottom adjustment mechanism 2 includes the bottom connecting horizontal plate 2-1, the bottom rolling short axis 2-2, the bottom side plate 2-3, the bottom rolling long Axis 2-4, bottom hinge one 2-5, bottom connecting rod 2-6, bottom connecting shaft 2-7, bottom hinge two 2-8, bottom two-way threaded rod 2-9, bottom motor 2-10, bottom The short rolling axis 2-2 is rotatably installed in the groove provided on the bottom connecting horizontal plate 2-1, the bottom connecting horizontal plate 2-1 is fixedly connected with the bottom side plate 2-3, and the bottom rolling long axis 2-4 is rotatably installed on In the groove provided on the bottom side plate 2-3, the two ends of the bottom side plate 2-3 are respectively fixed with a bottom hinge piece 2-5, and the bottom hinge piece 2-5 is hinged with the bottom connecting rod 2-6 , the bottom connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com