Polishing head for chemical polishing device and chemical polishing device with polishing head

A technology of chemical grinding device and grinding head, which is applied in the direction of grinding device, grinding machine tool, grinding tool, etc. It can solve the problem that the asymmetric difference of the inner film thickness of the wafer cannot be eliminated by CMP, so as to facilitate the promotion and improve the uniformity of grinding , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

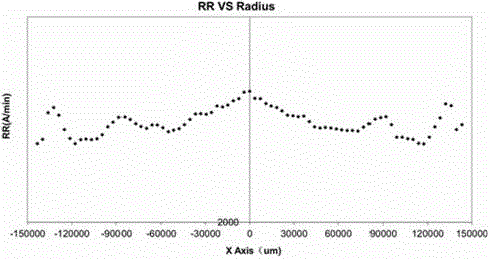

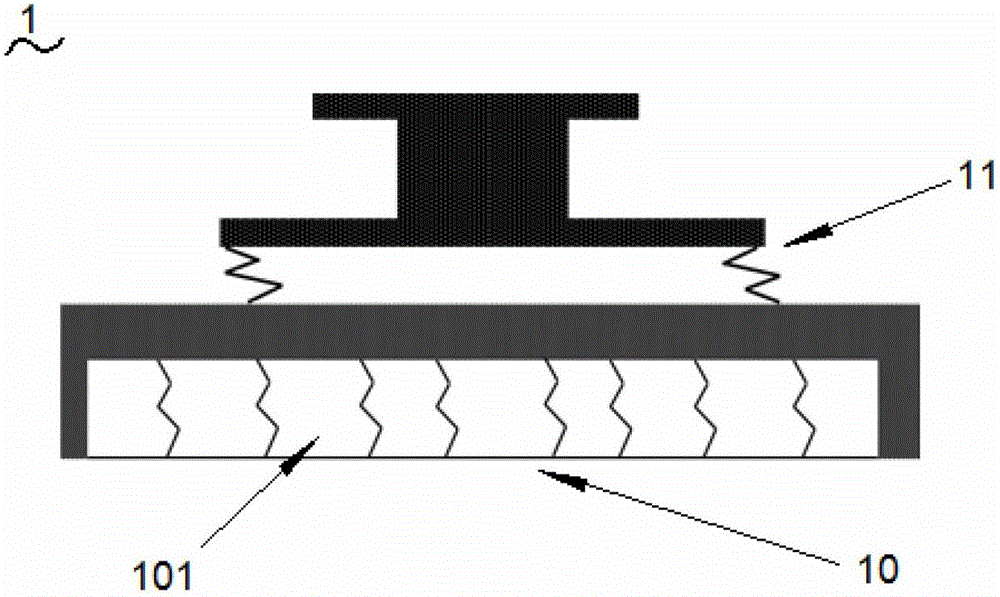

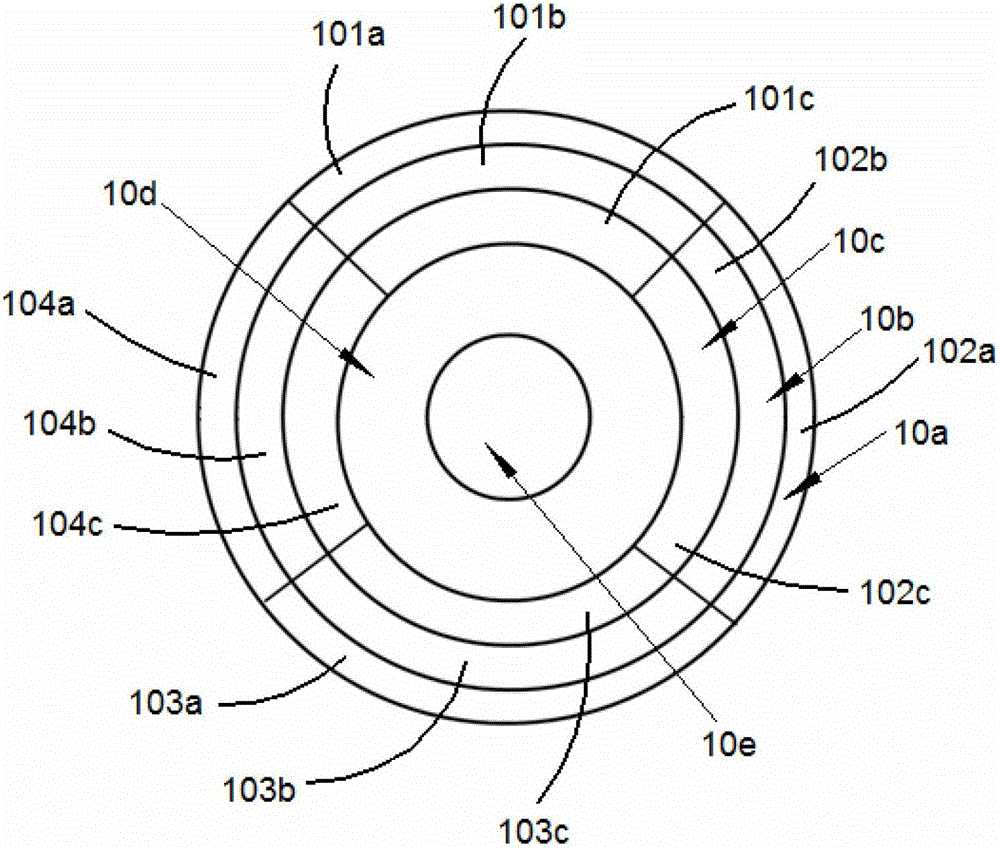

[0026] see figure 1 , figure 2 , figure 1 Shown is a side view of a polishing head for a chemical polishing apparatus according to the present invention. figure 2 Shown is a top view of the polishing head used in the chemical polishing device of the present invention. The grinding head 1 includes a concentric annular grinding area 10 with an independent grinding sub-area 101. The concentric annular grinding area 10 is centered on the center of the grinding head 1 and distributed symmetrically. The independent grinding sub-area 101; the force applying device 11, the force applying device 11 acts on the grinding head 1, and independently controls the force of each grinding sub-area 101. Wherein, the said force applying device 11 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com