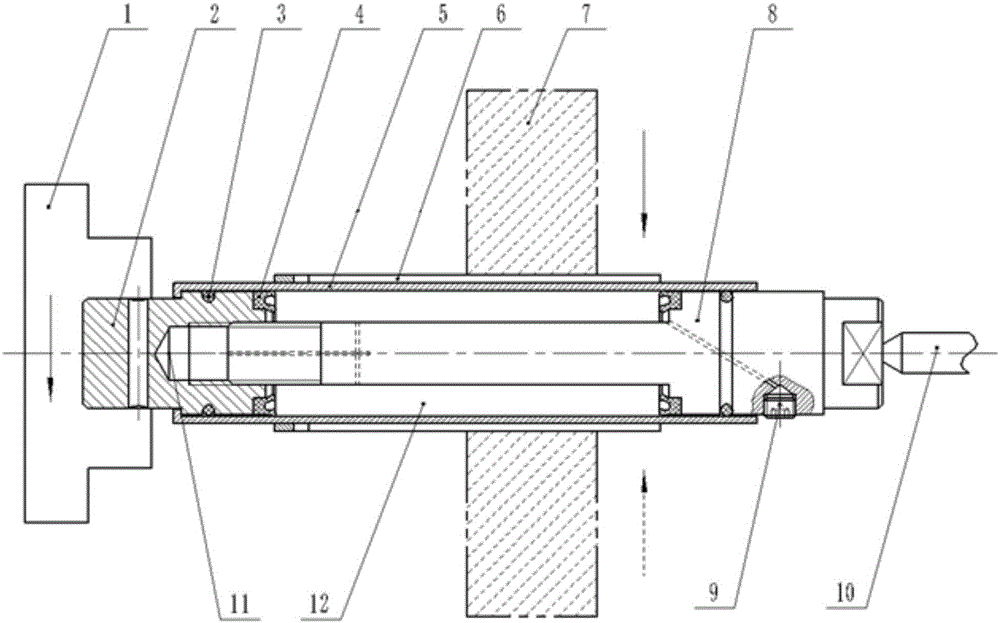

Liquid expansion type precision grinding tool for inner hole

An inner hole and precision technology is applied in the field of liquid expansion type inner hole precision grinding tooling, which can solve the problems of saddle shape error, reduce the installation and positioning accuracy of the inner hole, and poor positioning accuracy, and achieve simple structure and good market application prospects and promotion. The effect of value, ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

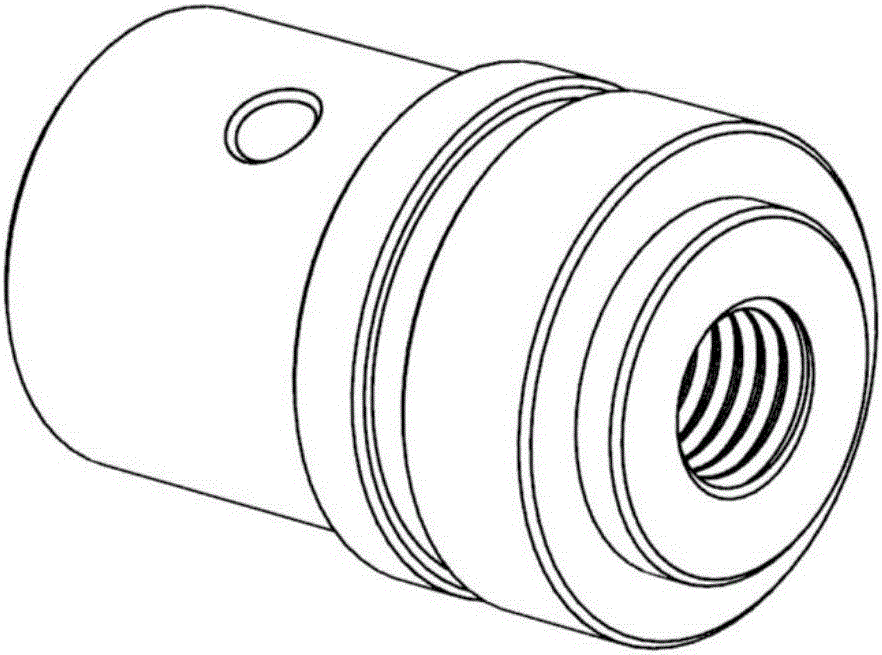

[0019] 1. Finishing plunger nut and plunger screw

[0020] Process the plunger surface, the U-shaped groove on the plunger nut 2 and the plunger screw 8 and the ring groove on the end face according to the diameter of the workpiece to be ground and the size of the selected standard O-shaped seal ring 3 and Y-shaped seal ring 4. Reasonably select the length of the plunger screw 8.

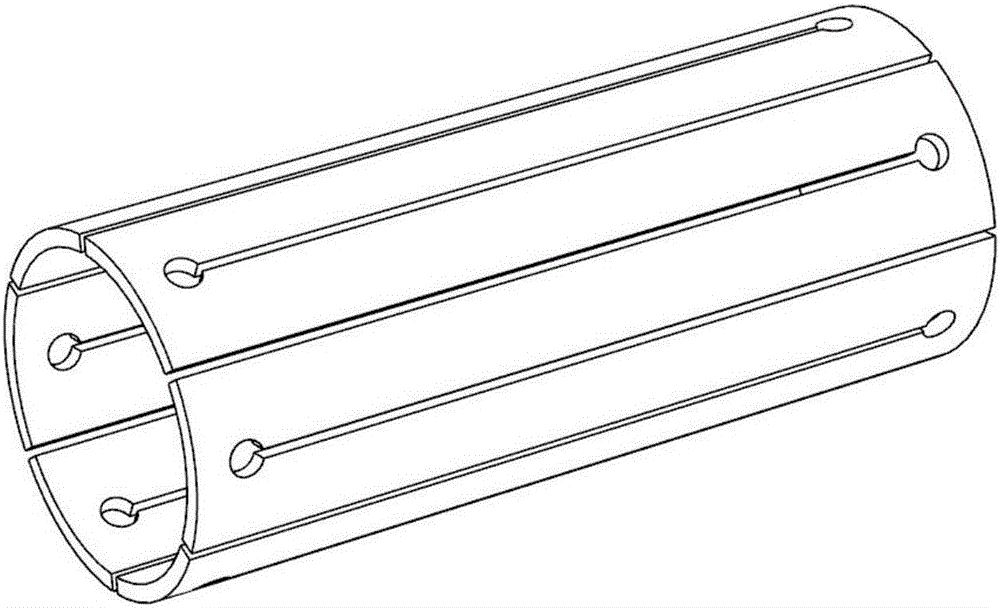

[0021] 2. Finishing expansion sleeve

[0022] First finish the inner hole of the expansion sleeve 5 to the design size; then put the plunger nut 2 with the sealing ring into the expansion sleeve 5 after finishing the inner hole, and place it vertically; add an appropriate amount of 46# or After 68# medium viscosity anti-wear hydraulic oil, screw the plunger screw 8 into the plunger nut 5 for about half the distance and the hydraulic oil flows out from the oil outlet hole. At this time, the hydraulic oil has filled the chamber of the expansion mandrel. ; Then screw the oil plug 9 screw into the oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cylindricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com