Rotatable gear machining and polishing device

A technology of gears and rotating rods, which is applied in the direction of grinding drive devices, machine tools designed for grinding the rotating surface of workpieces, metal processing equipment, etc., and can solve the problems of inability to meet the needs of gear grinding, poor adjustment flexibility, and inconvenient use. , to achieve the effects of improving practicability, facilitating control and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

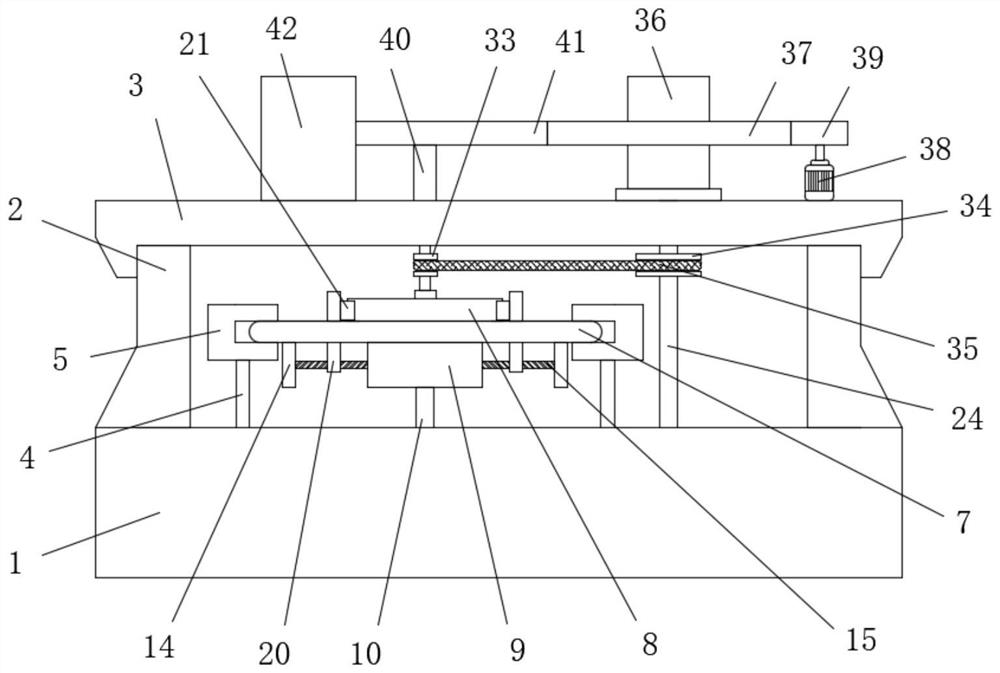

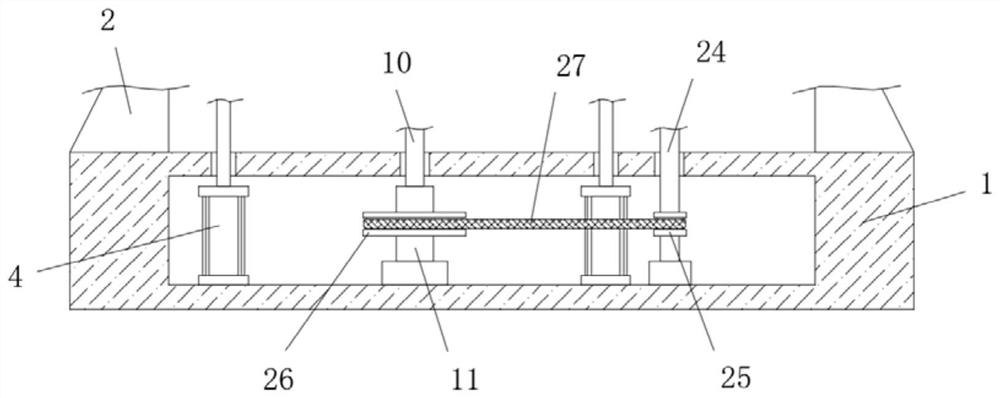

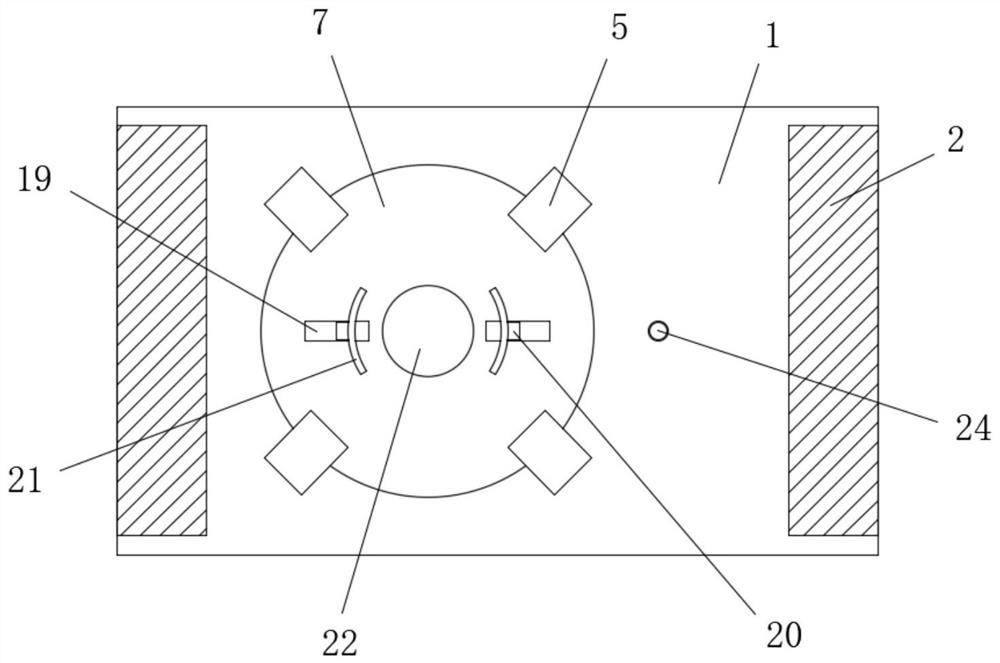

[0033] refer to Figure 1-9 , a rotatable gear processing and grinding device, comprising a base 1, the base 1 is a hollow structure, two vertical plates 2 are fixedly connected symmetrically to both sides of the top outer wall of the base 1, and the tops of the two vertical plates 2 are fixedly connected to the same The top plate 3 and the base 1 are fixedly connected with four lifting cylinders 4, and the four lifting cylinders 4 are arranged in a square, and the tops of the four lifting cylinders 4 all extend to the top of the base 1 and are fixedly connected with lifting blocks 5. The sides of each lifting block 5 that are close to each other are provided with grooves 6, and the same circular plate 7 is slidably connected in the four grooves 6, and a processing gear 8 is movably placed at the center of the top of the circular plate 7, and the top of the circular plate 7 A circular groove 22 is provided at the center of the circle, and two sets of clamping assemblies for cl...

Embodiment 2

[0035] Further improved on the basis of Embodiment 1: the rotating assembly includes a slide bar 10 fixedly connected to the outer wall of the bottom of the square block 9, one side of the slide bar 10 extends to the inside of the base 1 and a sleeve 11 is slidably sleeved on the sleeve. The bottom end of 11 is connected with the bottom inner wall of the base 1 in rotation, and the rotation of the sleeve 11 drives the slide bar 10 to rotate, which can drive the square block 9 to rotate, and then drives the circular plate 7 to rotate. The inner wall of the sleeve 11 is annularly provided with multiple Draw-in slot 12, one side outer wall of slide bar 10 is annularly provided with a plurality of draw-in strips 13, and a plurality of draw-in bars 13 are slidably connected in a plurality of draw-in grooves 12 respectively, through the cooperation of draw-in bar 13 and draw-in groove 12, when When the sleeve 11 rotates, it can drive the slide bar 10 to rotate. The two groups of clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com