Fine finish polishing tool

A technology for grinding tools and grinding parts. It is applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc. It can solve the problems of unfavorable control of grinding fluid and flow temperature, cumbersome processing of panel glass, and reduced processing success rate, so as to improve grinding. Efficiency, increase the success rate, improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

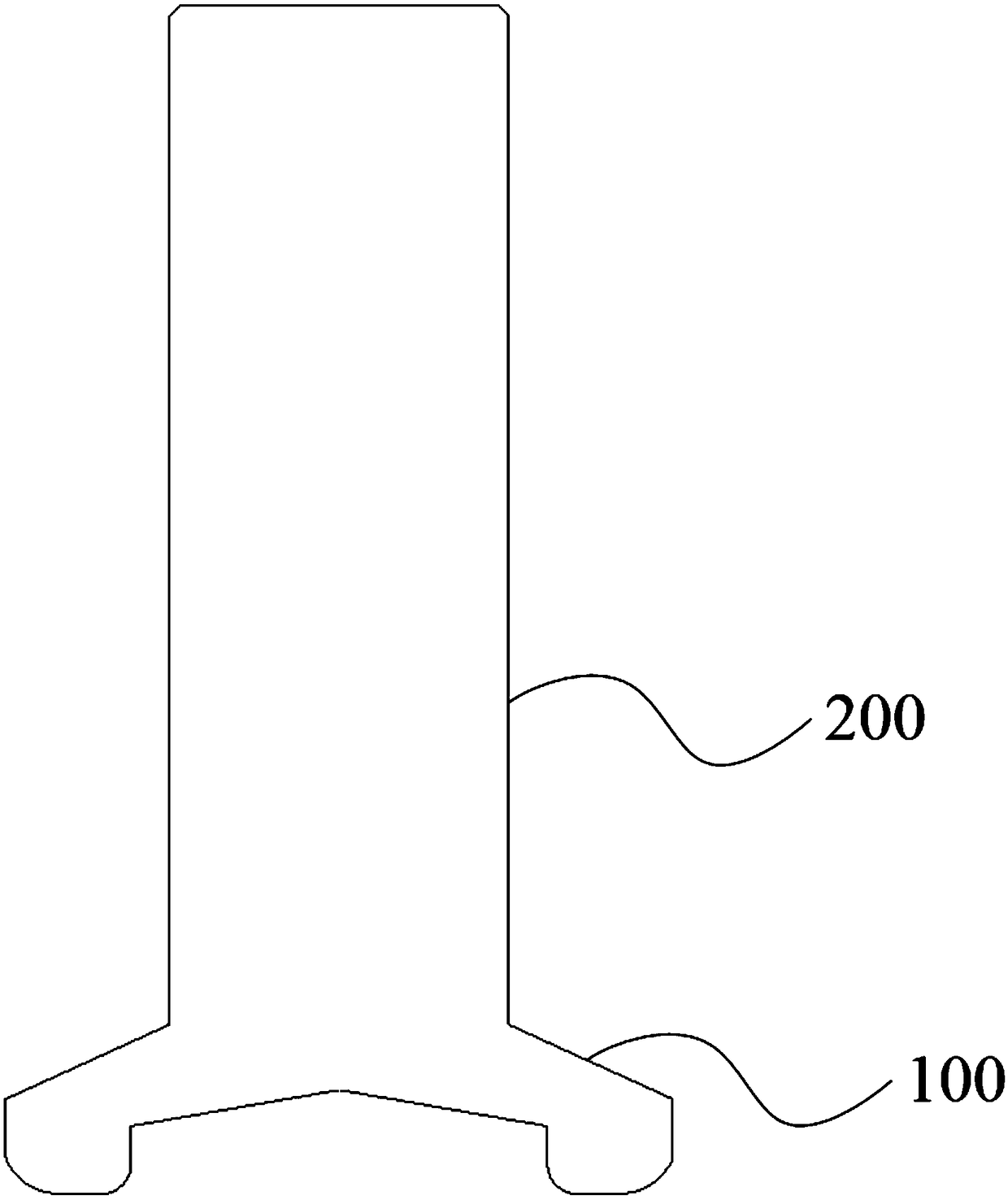

[0057] see figure 1 , figure 1 It is a schematic cross-sectional structure diagram of a finishing grinding tool provided in this embodiment.

[0058] Such as figure 1 As shown, this finishing grinding tool includes a grinding main body 100 and an installation connecting rod 200, wherein,

[0059] The installation connecting rod 200 is cylindrical, the grinding main body 100 is disc-shaped, the installation connecting rod 200 is coaxially connected with the grinding main body 100, and the ratio of the diameter of the grinding main body 100 to the diameter of the installation connecting rod 200 is 1.2-2.4;

[0060] The grinding body 100 includes a connecting portion 120 and a grinding portion 110;

[0061] The shape of the connecting portion 120 is a truncated cone, with a circular top surface and a bottom surface, and a side surface shaped as a conical surface; the diameter of the top surface is smaller than the diameter of the bottom surface; the top surface is connected co...

Embodiment 2

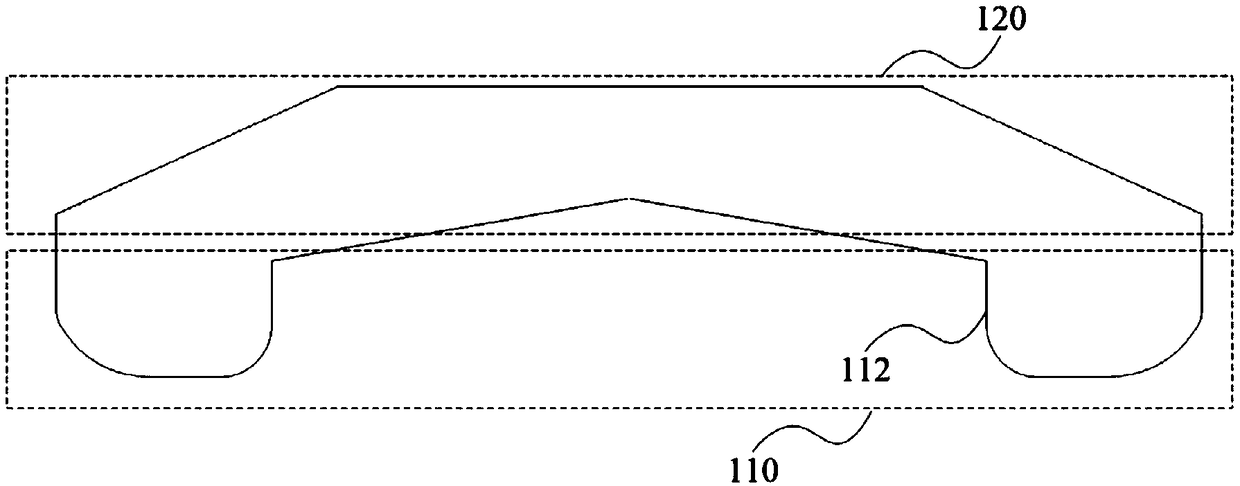

[0085] see figure 2 , figure 2 yes figure 1 A partial sectional structural schematic diagram of a sectional structural schematic diagram of a finishing grinding tool is provided.

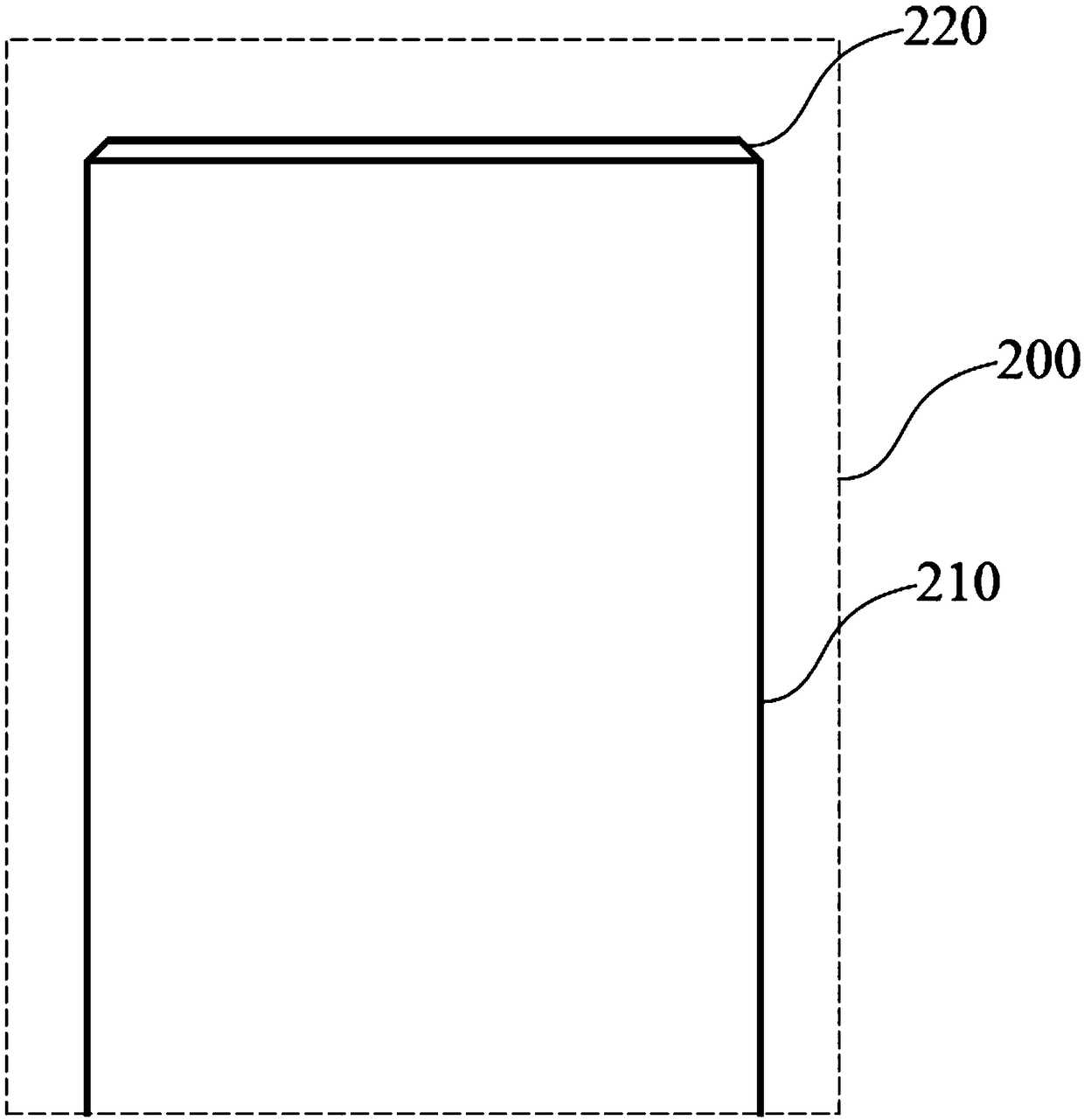

[0086] see image 3 , image 3 yes figure 1 A partial sectional structural schematic diagram of a sectional structural schematic diagram of a finishing grinding tool is provided.

[0087] Such as figure 2 and image 3 As shown, in the grinding main body 100, the discharge groove 111 is in the shape of a prism;

[0088] The taper angle of the connecting portion 120 is 145° to 170°.

[0089] In this embodiment, the bottom surface of the grinding main body 100 can be a conical surface, which can provide an internal space for grinding and is convenient for shaping; meanwhile, the inner surface of the conical surface can also provide ventilation and heat dissipation for grinding, and limit the splashing of grinding powder etc.

[0090] In this embodiment, the angle of the side of the round t...

Embodiment 3

[0118] On the basis of Embodiment 1 or Embodiment 2, in the finishing grinding tool, the axial length of the connecting part 120, the axial length of the grinding part 110 and the axial length of the connecting rod 200 satisfy the following relationship:

[0119] a*L=X+Y;

[0120] Among them, a is a preset constant coefficient, the size is 0.15 ~ 0.25;

[0121] L is the axial length of the connecting rod 200;

[0122] X is the axial length of the connecting portion 120;

[0123] Y is the axial length of the grinding part 110 .

[0124] As an optional implementation manner, the axial length of the connecting portion 120 and the axial length of the grinding portion 110 satisfy the following relationship:

[0125] Y=b*X;

[0126] Among them, b is a preset constant coefficient, the size is 0.15 ~ 0.25.

[0127] As an optional embodiment, the peripheral arc length of the discharge groove 111 and the peripheral arc length of the grinding section 112 satisfy the following relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com