The combined clamp for grinding small circular handle special-shaped blade edge

A technology of combining fixtures and fixtures, applied in the direction of grinding workpiece supports, etc., can solve the problems of high requirements for sharpness and surface finish, high labor intensity, high dimensional tolerances and geometric tolerances, and achieve automatic grinding and grinding. High efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

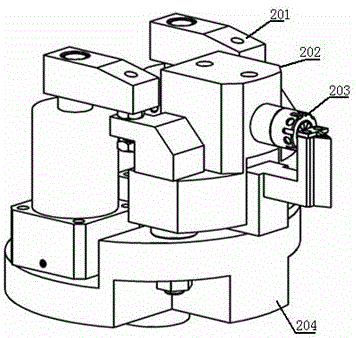

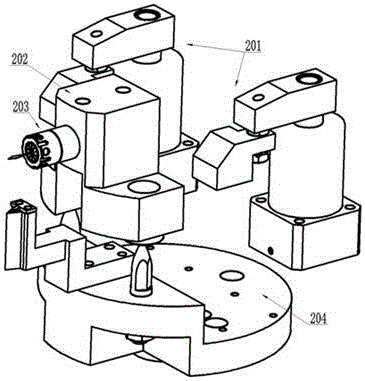

[0022] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0023] Such as Figure 1 to Figure 11 As shown, the combination clamp for grinding the edge of a micro-shaped special-shaped blade with a round handle in the present invention includes a rotary cylinder 201, a clamp base 202, a clamp handle 203, a clamp base 204, and a screw 604, and the clamp base 204 is provided with a screw hole 1005 , the two rotating cylinders 201 are fixed on the fixture base 204 through screws 604 and screw holes 1005, the fixture base 202 is assembled on the fixture base 204, the fixture base 202 is fixed with the fixture base 204 through the two rotating cylinders 201, the fixture base 202 is located between the two rotary cylinders 201 , and the clamp base 202 is provided with a clamping handle 203 .

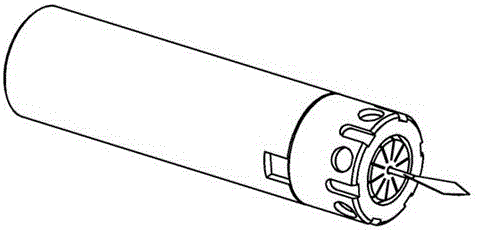

[0024] Such as Figure 4 As shown, the clamping handle 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com