Novel powder metallurgy deburring machine tool

A powder metallurgy and deburring technology, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece edges, grinding machines, etc. It can solve the problems of high product rejection rate, product damage, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

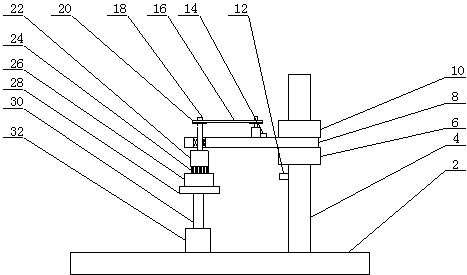

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] The present invention includes a frame and a workbench 8 that is horizontally arranged on the frame 2 and can be raised and lowered. A brush head 22 driven to rotate by a rotating device is arranged on the workbench 8. A plurality of brush filaments 24 are fixedly arranged at the lower end of the brush head 22. The feature is that a fixed seat 28 for fixing the workpiece 26 is provided directly under the brush head 22, and the bottom of the fixed seat 28 is connected to the cylinder arm 30 of a cylinder 32, which is used to push the fixed seat 28 up and down. Put the workpiece 26 on the fixed seat 28, the cylinder 32 works, the cylinder arm 30 goes up, pushes the fixed seat 28 upwards until it contacts the brush wire 24, and the brush wire 24 rotates to polish and deburr the workpiece 26. This method does not need When the operator manually stops the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com