Edge grinding chamfering device and method for pipe fitting socket

A technology for pipe fittings and chamfering machines, which is applied to grinding drive devices, machine tools suitable for grinding workpiece edges, grinding machines, etc. The effect of improving accuracy and efficiency, saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

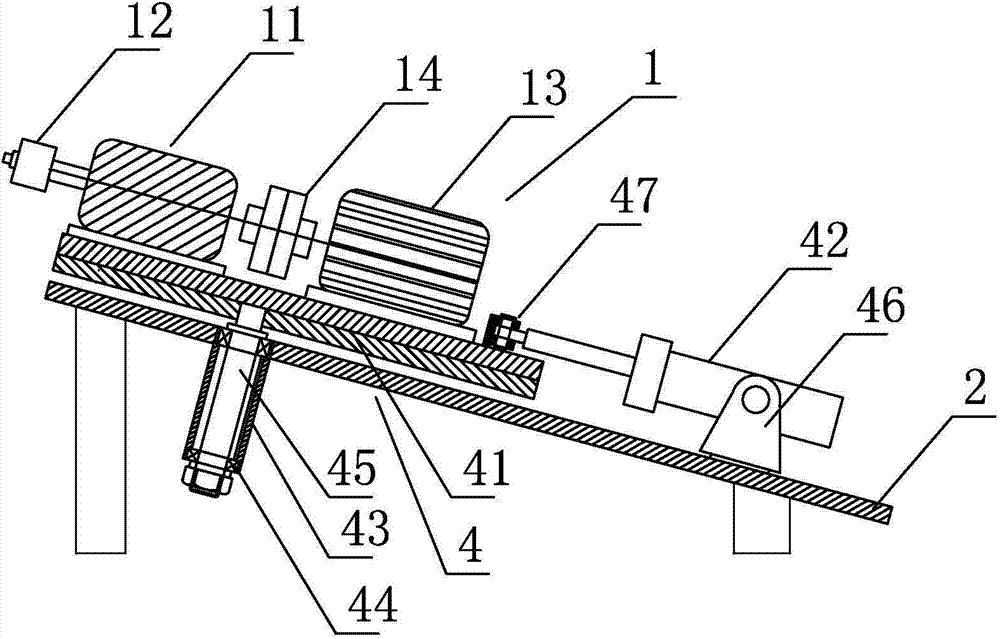

[0020] Such as figure 1 As shown, the pipe fitting socket edge grinding and chamfering device in this embodiment includes a grinding device 1, a support 2 for installing the grinding device 1, and a support bracket 3 for supporting a pipe fitting. Specifically, the grinding device 1 includes a chamfering Angle machine 11, grinding wheel 12 installed on the output shaft of chamfering machine 11 and motor 13 driving chamfering machine 11, chamfering machine 11 is connected with motor 13 through shaft coupling 14, motor 13 is connected with PLC control system, PLC control The system sends a command to the motor 13 to start the grinding device 1 to work or to stop working.

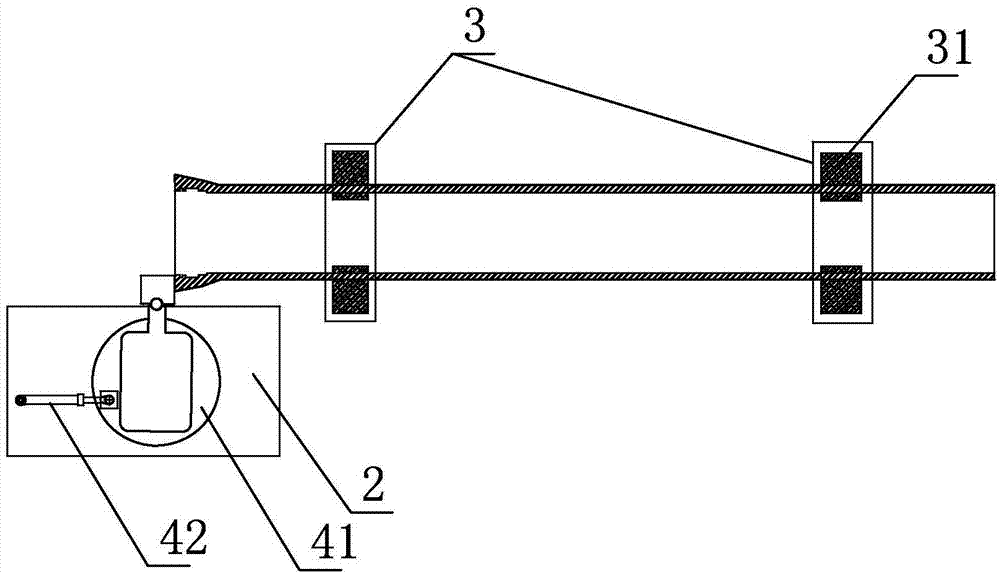

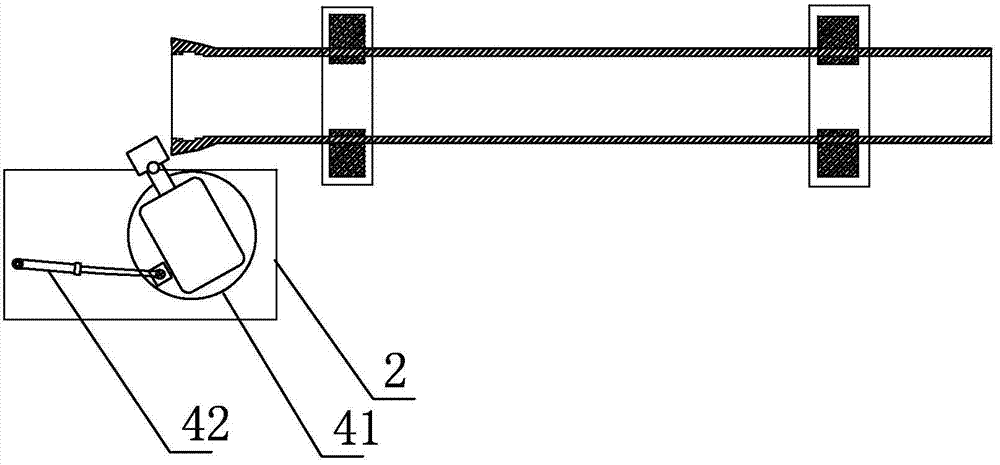

[0021] Such as figure 1 and 2 As shown, in order to realize the automatic switching between edging and chamfering, the grinding device 1 of this embodiment is installed on the support 2 by means of the rotating device 4 to realize the adjustment of the grinding angle. Specifically, the rotating device 4 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com