Grinding wheel with array-type region grinding function

An array type, grinding wheel technology, applied in the field of grinding wheels, can solve the problems of inability to meet high-speed, large grinding volume, and inability to meet the needs of high-speed rail grinding, and achieve long-term online rail grinding, short grinding life, and grinding. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

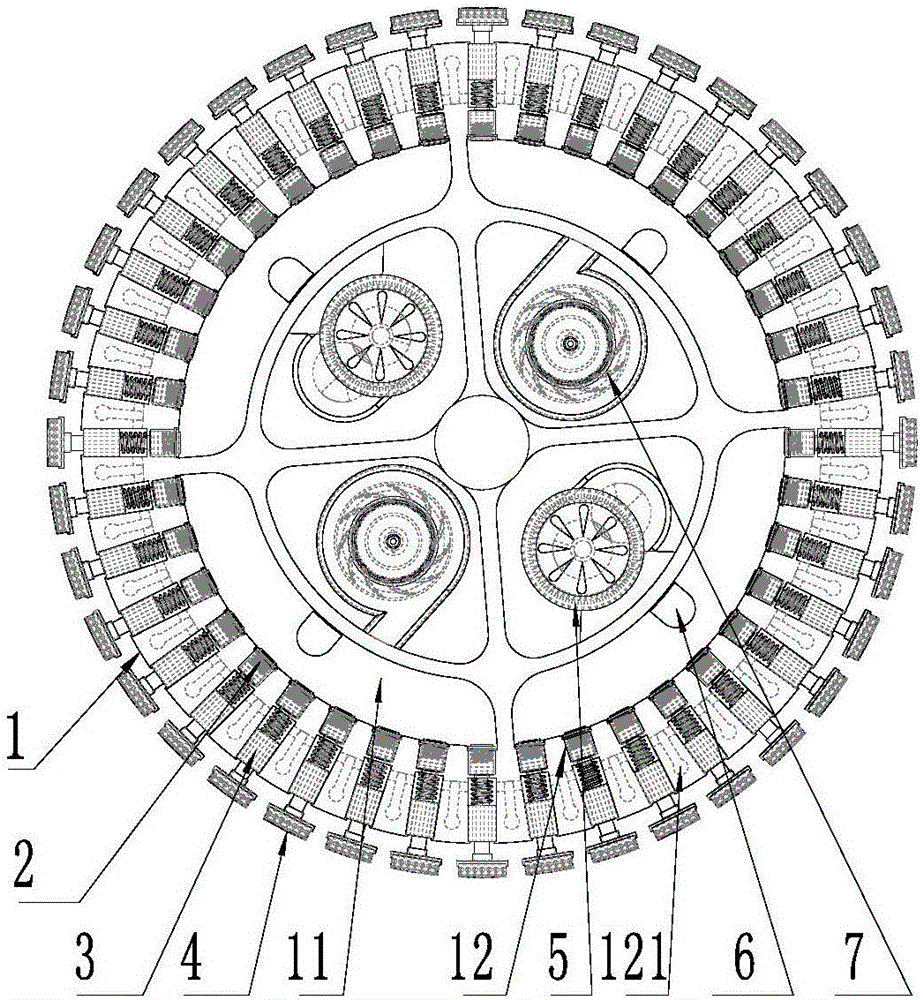

[0023] The invention provides a grinding wheel capable of array surface area polishing, which includes a grinding wheel main body, which is a rigid rotating wheel.

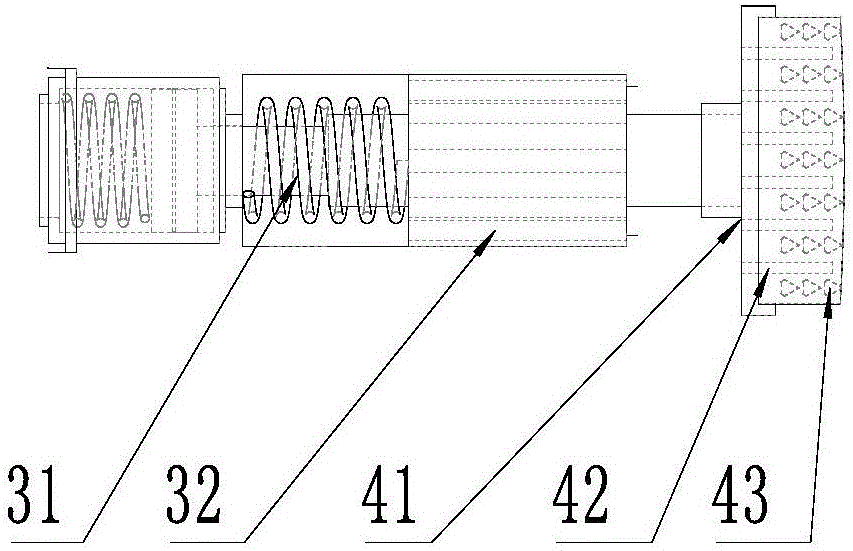

[0024] The middle part of the grinding wheel body is provided with one or several air storage cavities for storing compressed air; the grinding wheel body is provided with one or several small air compressors, and the air outlet of the small air compressors is connected with the air storage cavity. The opening and closing and speed regulation of the air compressor are controlled by the remote control device. The main body of the grinding wheel is provided with a high-pressure blower for delivering high-pressure and high-speed airflow to the airflow cooling channel, and the airflow cooling channel includes the first airflow cooling channel, the second airflow cooling channel, and the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com