High-speed grinding diamond grinding disc and manufacturing process thereof

A manufacturing process and diamond technology, which is applied in the field of high-speed grinding of diamond grinding discs and its manufacturing process, can solve the problems that sand and gravel dust cannot be discharged in time and block the grinding surface of the cutter head, so as to avoid a large amount of heat accumulation and reduce the grinding temperature , Improve the effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

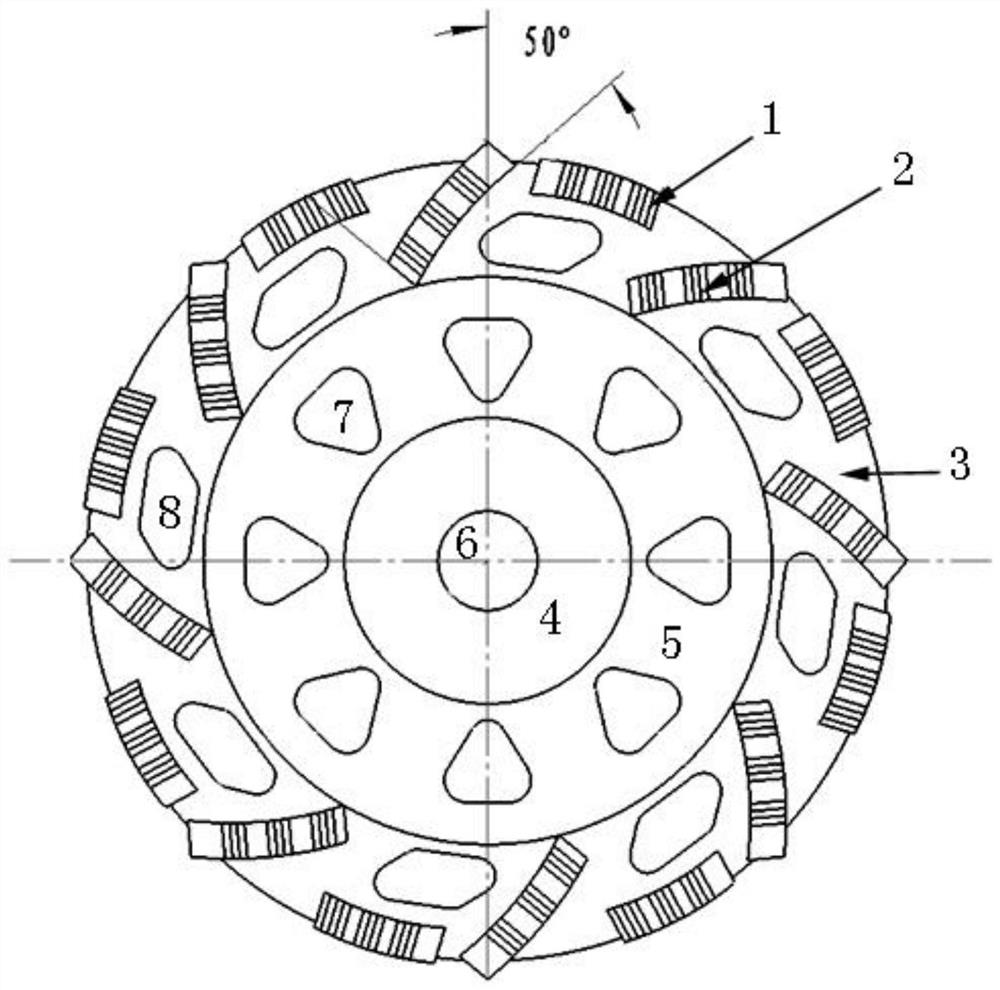

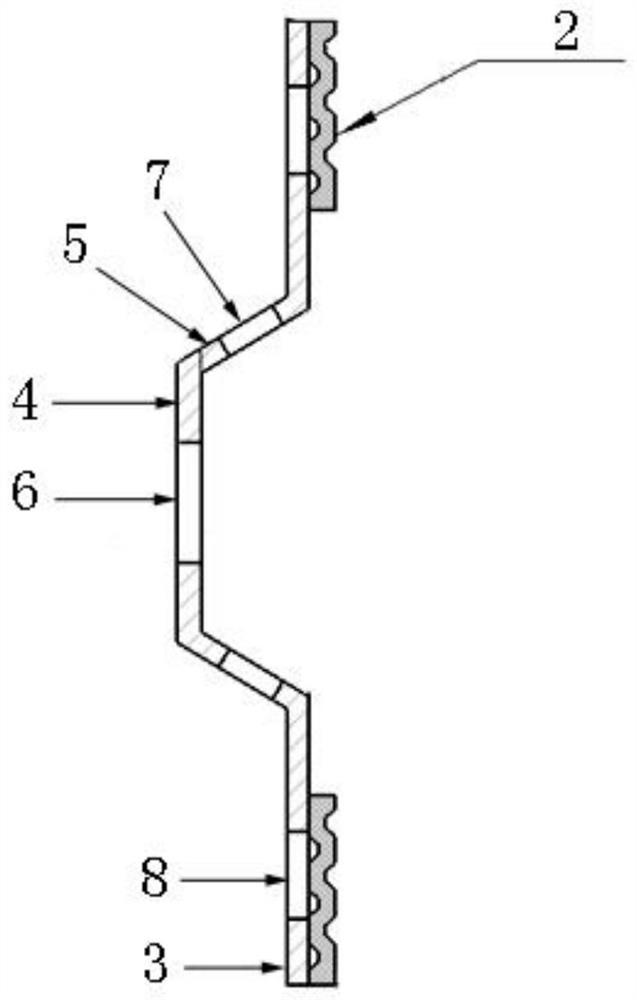

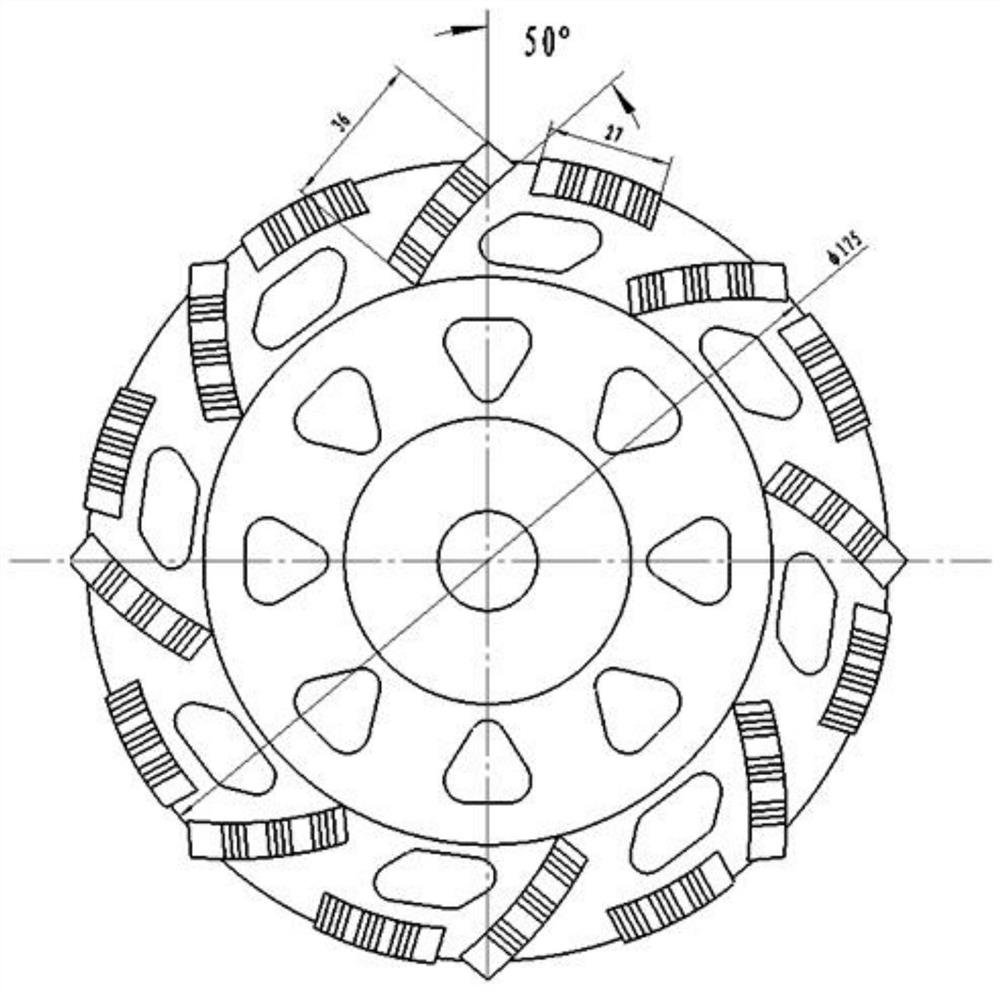

[0051] This embodiment is a manufacturing process of a diamond grinding disc, and the design dimensions are as follows Figure 3-4 As shown, the manufacturing process includes the following steps:

[0052] (1) Substrate processing:

[0053] According to the requirements of the drawing, turn and cut the required matrix structure;

[0054] (2) Sintering of diamond cutter head:

[0055] Take 2.6kg of copper powder, 3.76kg of iron, 0.8kg of nickel, 0.95kg of zinc, 0.84kg of tin, and 0.75kg of manganese, put them into the mixing tank and mix for 30 minutes, add 0.09kg of liquid paraffin, 0.2kg of diamond, and continue mixing After 3 hours, the powder is poured into the mold and cold-pressed, and then hot-pressed and sintered to obtain the cutter head blank, which is polished by a grinding wheel and abrasive belt to obtain the diamond cutter head; wherein: the hot-pressed sintered The sintering temperature is 702°C and the pressure is 310kg / cm 2 , the holding time is 3 minutes; ...

Embodiment 2

[0061] The present embodiment is the manufacturing process of diamond grinding disc, and the design size is the same as embodiment 1, and the manufacturing process comprises the following steps:

[0062] (1) Substrate processing:

[0063] According to the requirements of the drawing, turn and cut the required matrix structure;

[0064] (2) Sintering of diamond cutter head:

[0065] Take 2.95kg of copper powder, 3.8kg of iron, 0.7kg of nickel, 0.9kg of zinc, 0.8kg of tin, and 0.75kg of manganese, put them into the mixing tank and mix for 30 minutes, add 0.08kg of liquid paraffin, 0.17kg of diamond, and continue mixing After 3 hours, the powder is poured into the mold and cold-pressed, and then hot-pressed and sintered to obtain the cutter head blank, which is polished by a grinding wheel and abrasive belt to obtain the diamond cutter head; wherein: the hot-pressed sintered The sintering temperature is 710°C and the pressure is 300kg / cm 2 , the holding time is 3 minutes;

[...

Embodiment 3

[0071] The present embodiment is the manufacturing process of diamond grinding disc, and the design size is the same as embodiment 1, and the manufacturing process comprises the following steps:

[0072] (1) Substrate processing:

[0073] According to the requirements of the drawing, turn and cut the required matrix structure;

[0074] (2) Sintering of diamond cutter head:

[0075] Take 3.2kg of copper powder, 3.8kg of iron, 0.9kg of nickel, 0.8kg of zinc, 0.7kg of tin, and 0.6kg of manganese, put them into the mixing tank and mix for 30 minutes, add 0.07kg of liquid paraffin, 0.14kg of diamond, and continue mixing After 3 hours, the powder is poured into the mold and cold-pressed, and then hot-pressed and sintered to obtain the cutter head blank, which is polished by a grinding wheel and abrasive belt to obtain the diamond cutter head; wherein: the hot-pressed sintered The sintering temperature is 705°C and the pressure is 310kg / cm 2 , the holding time is 3 minutes;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com