Resource-saving mechanical solid raw material grinding system for chemical industry production

A chemical production and resource-saving technology, applied in the direction of grain processing, etc., can solve the problems of not being able to meet the needs of chemical solid raw material grinding, solid raw material cannot be effectively and continuously discharged, and solid raw material grinding is not sufficient, so as to achieve low labor intensity, Prevents clogging and improves grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

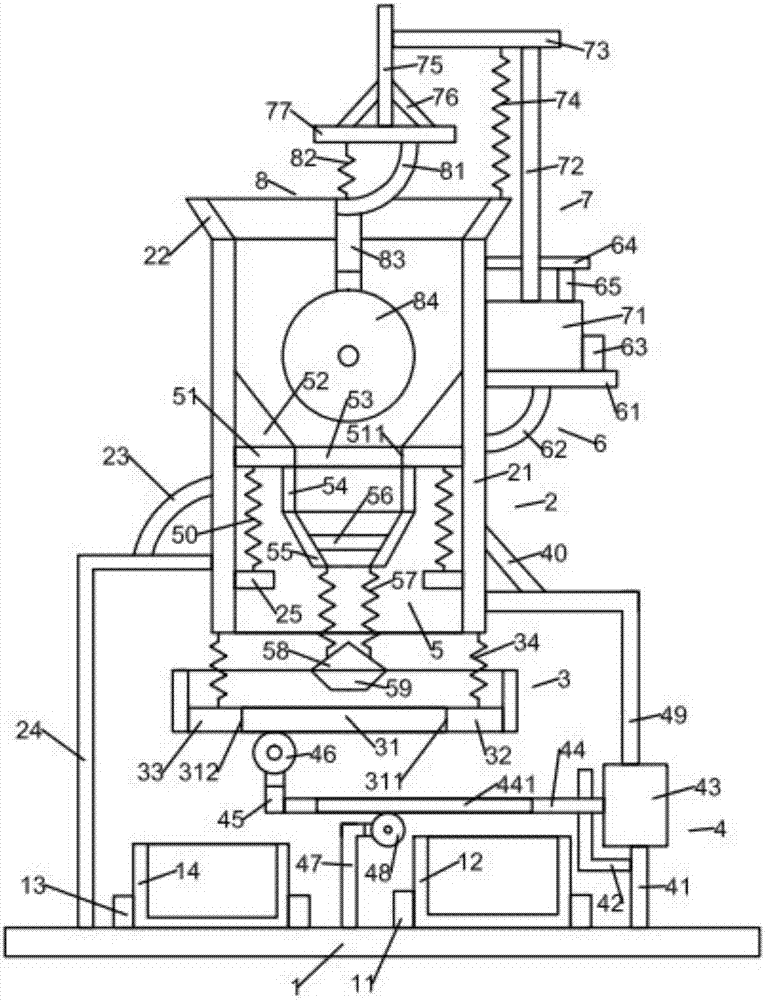

[0009] The resource-saving mechanical solid raw material grinding system for chemical production of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0010] Such as figure 1 As shown, the resource-saving mechanical solid raw material grinding system for chemical production of the present invention includes a bottom plate 1, a frame device 2 positioned above the bottom plate 1, a filter device 3 positioned below the frame device 2, and a filter device 3 positioned under the frame device 2. The supporting device 4 below the filter device 3, the concentrating device 5 accommodated inside the frame device 2, the fixing device 6 arranged on the frame device 2, and the electric cylinder device 7 arranged on the fixing device 6 . The grinding device 8 arranged on the electric cylinder device 7 .

[0011] Such as figure 1 As shown, the bottom plate 1 is rectangular parallelepiped and placed horizontally. The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com