Spiral pipe inner wall weld joint grinding device

A technology of spiral tube and servo drive device, which is applied to the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve the problems of low efficiency, different quality control, and difficult grinding operations, so as to ensure stability, The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments. It should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. In addition, it should be understood that after reading the content taught by the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

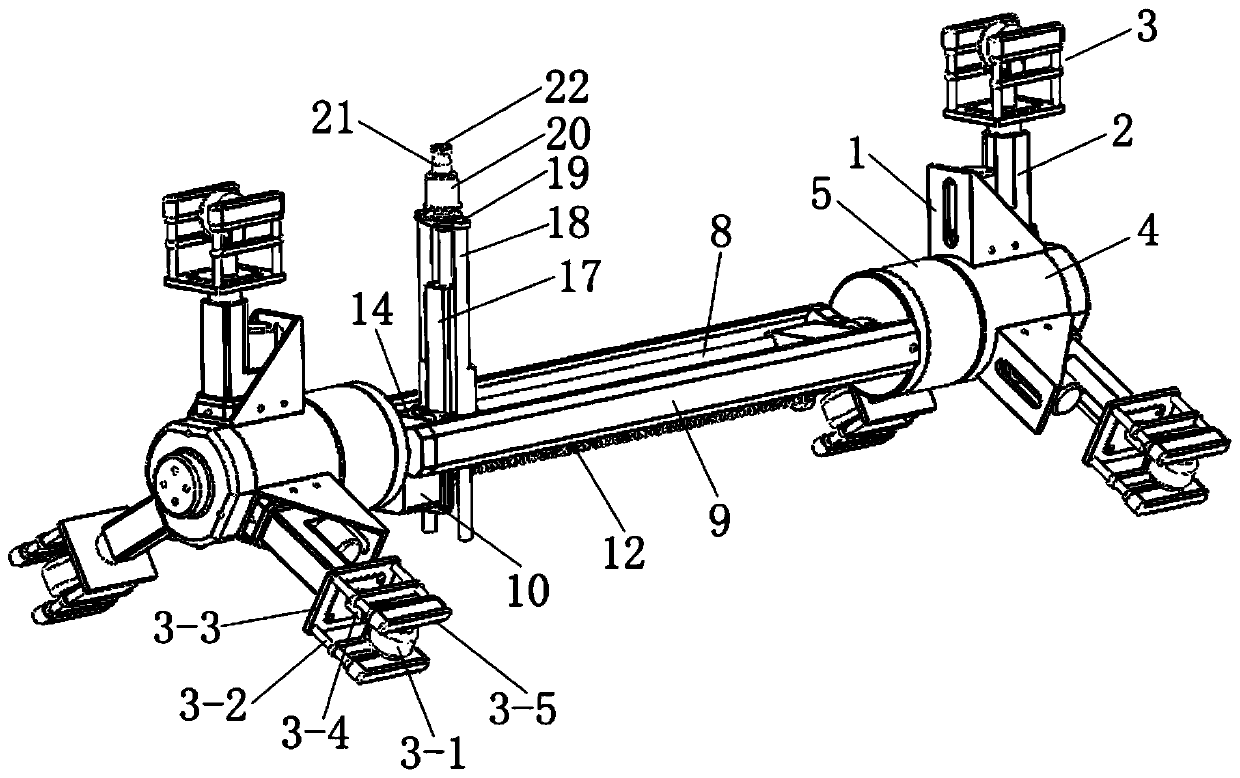

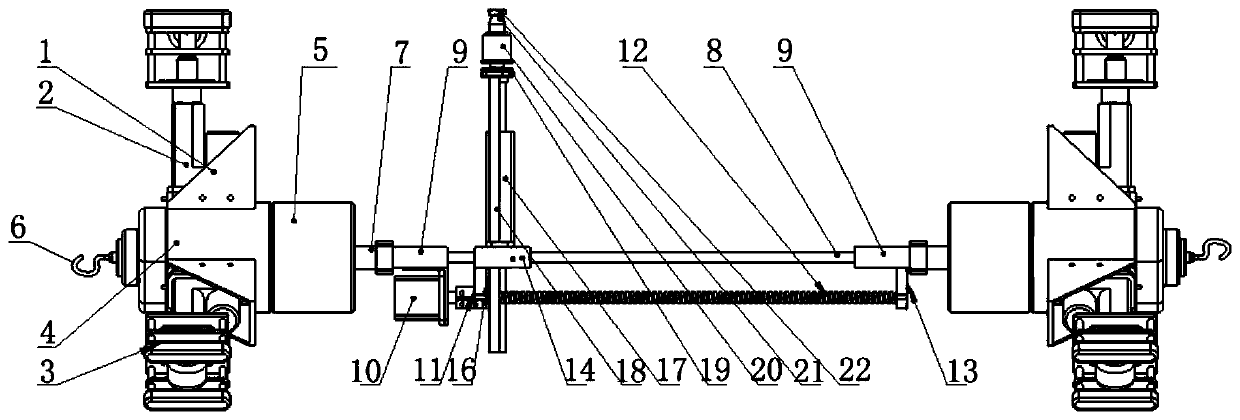

[0022] like figure 1 and figure 2 The shown device for grinding the inner wall of the spiral pipe includes a pipe support mechanism at both ends, a rotary feed mechanism and a grinding executive mechanism.

[0023] The pipeline support mechanism includes a central support base 4 and three self-lockable movable support feet 3 . The central support base 4 includes an integrally cast cylindrical hollow support shell and three m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com