Control method for workpiece automatic grinding

A control method and technology for workpieces, which are applied to automatic grinding control devices, machine tools suitable for grinding workpiece planes, and grinding machines, can solve the problems of reducing workpiece production efficiency, unfavorable rapid production, and high labor costs, and improve grinding efficiency. , The effect of saving manpower and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

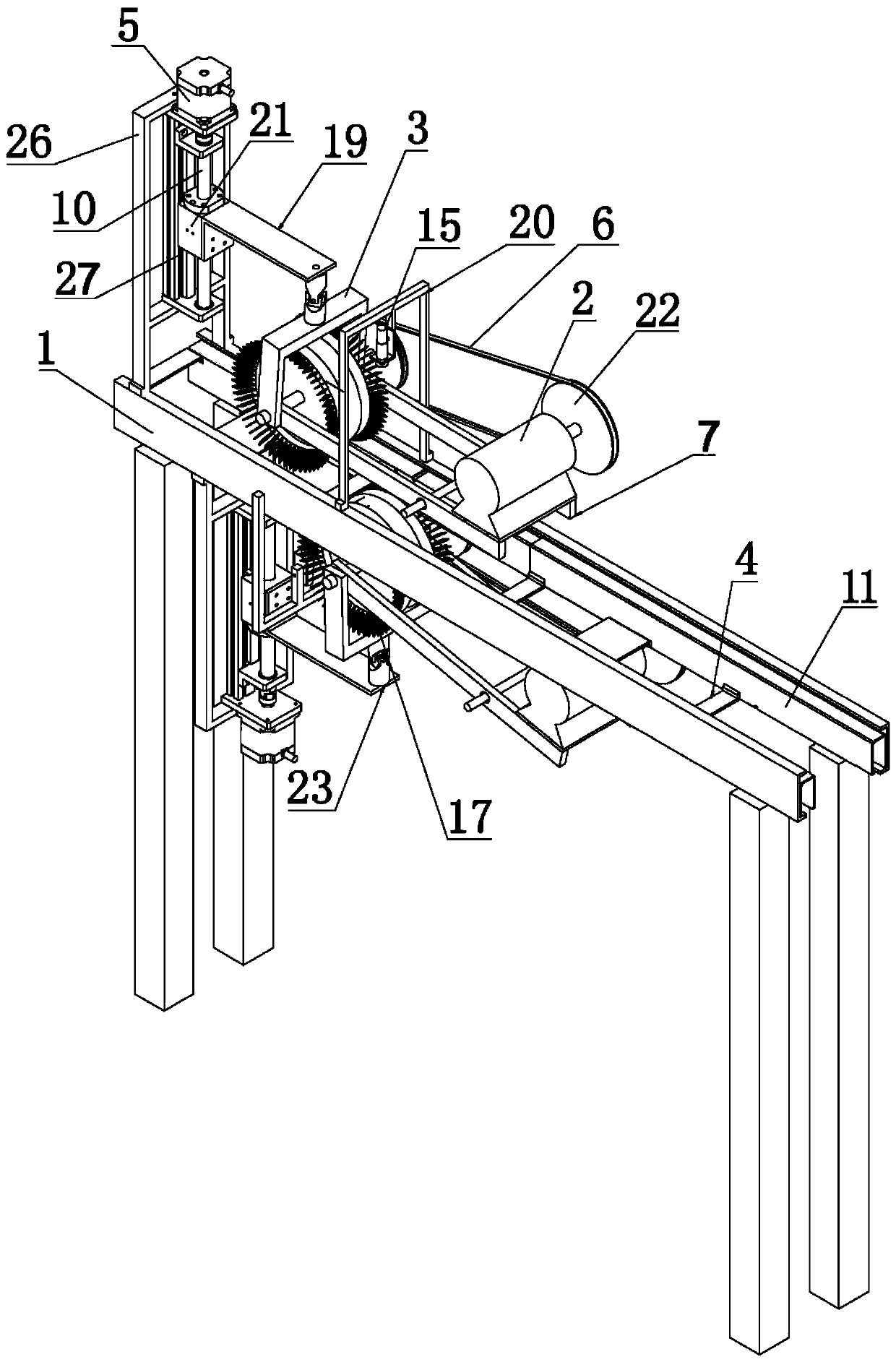

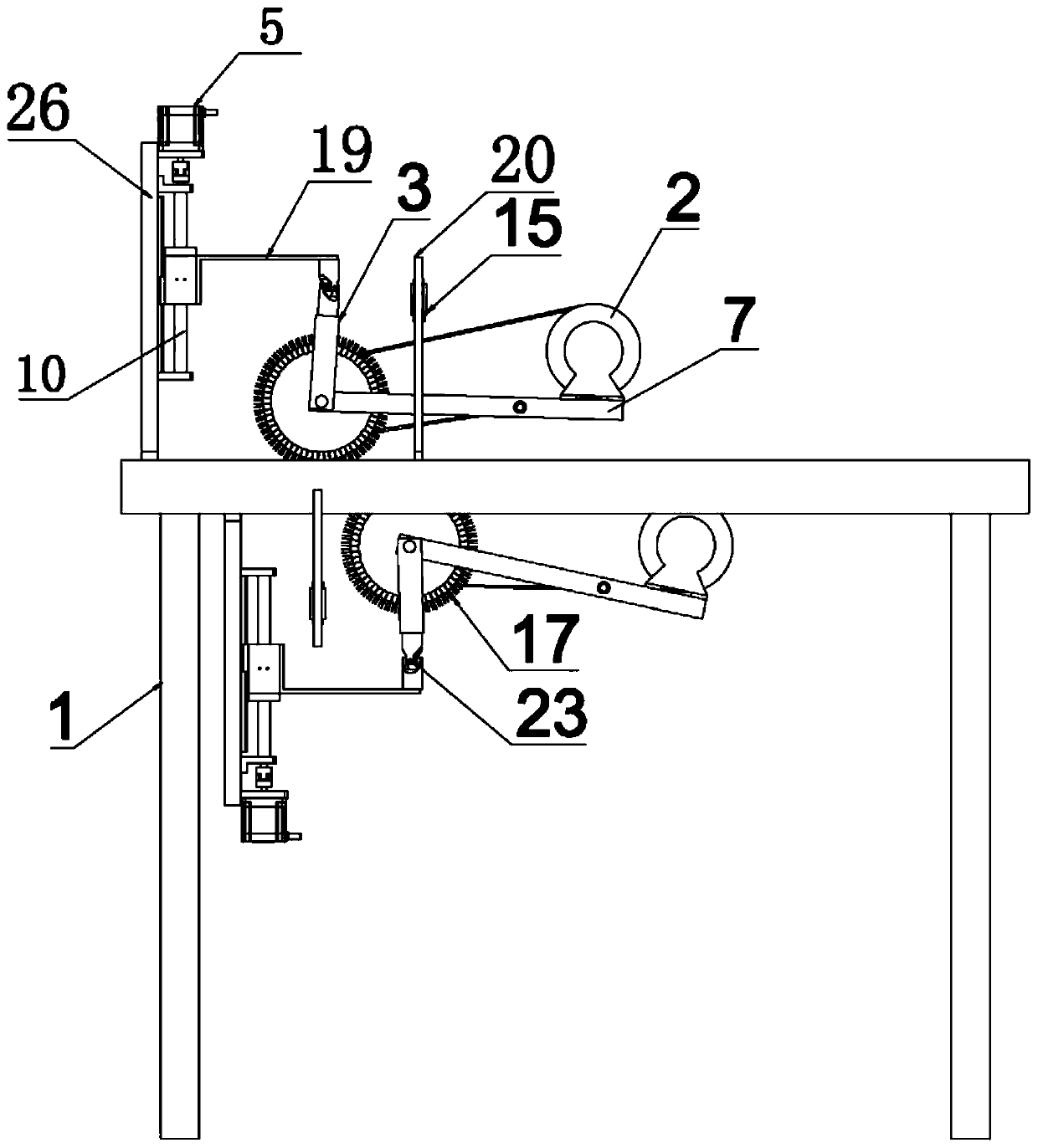

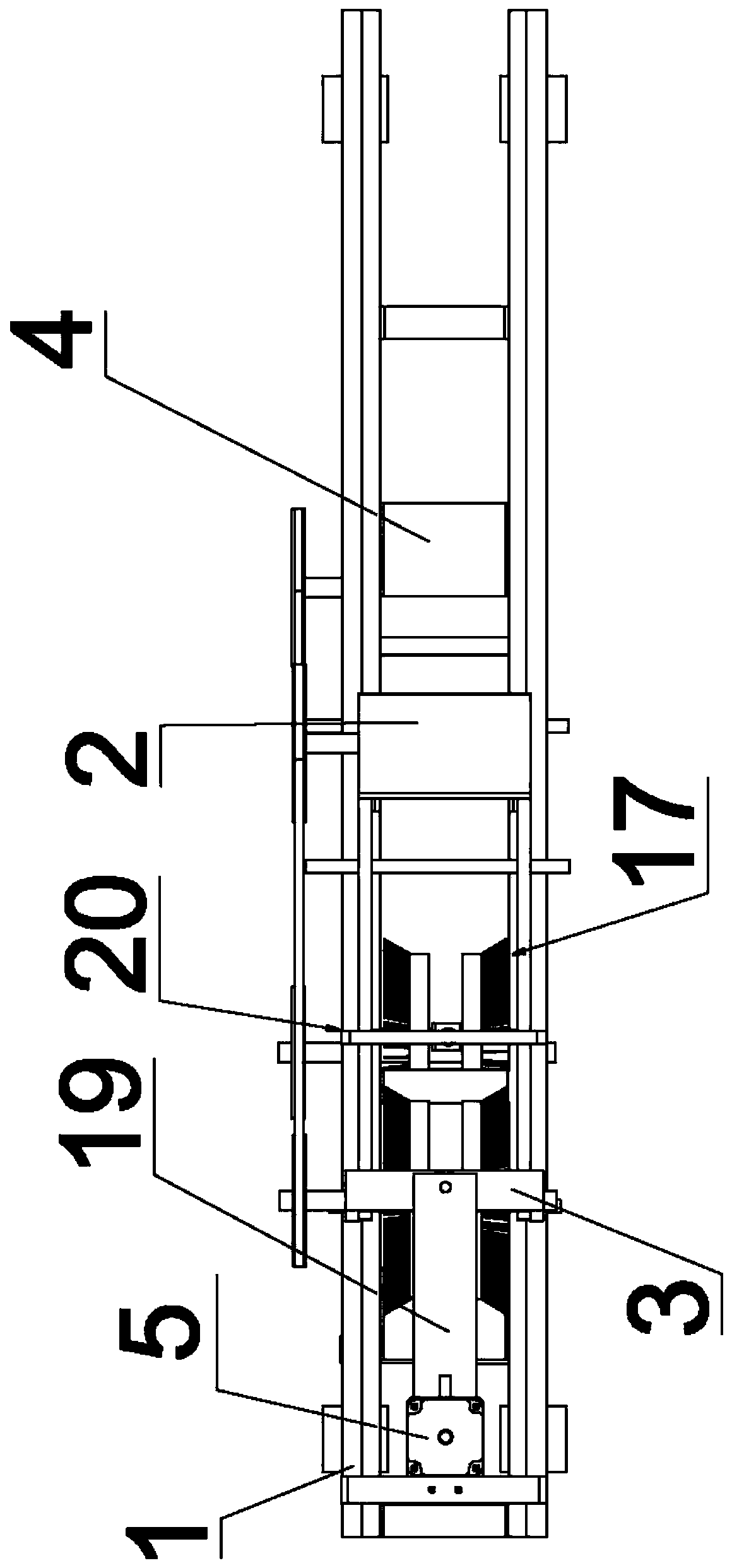

[0026] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention relates to a kind of workpiece automatic grinding device, and it is used for the grinding of workpiece 4, and it is made of frame 1, lead screw support 26, lead screw 10, lead screw motor 5, lead screw seat 21, grinding wheel support 3 , Grinding wheel 17, sensor 15, motor support 7 and several parts such as motor 2 are formed.

[0027] Wherein, a guide rail 11 is installed on the frame 1 , and the guide rail 11 can be pushed by an external force to move along the frame 1 . The workpiece 4 is arranged on the guide rail 11 and is grinded in conjunction with the guide rail 11 .

[0028] The screw support 26 is fixed on the frame 1 . The lead screw 10 is pivotally connected to the lead screw bracket 26 . The screw support 26 is arranged vertically, and a vertical guide groove 27 is provided on it.

[0029] The lead screw motor 5 is installed on the lead screw bracket 26, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com