Method for preparing colored polyacrylonitrile fibers

The technology of polyacrylonitrile fiber and polyacrylonitrile is applied in the field of preparation of polyacrylonitrile fiber, which can solve the problems of uneven dyeing, difficulty in dyeing uniform color, increased cost, etc., and achieves simple preparation method and application performance. Stable, simplified dyeing and finishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

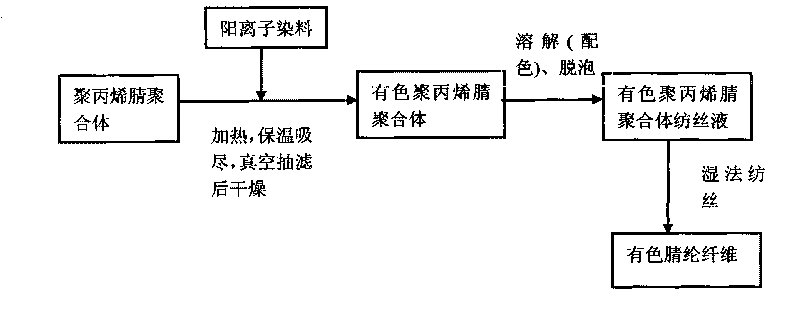

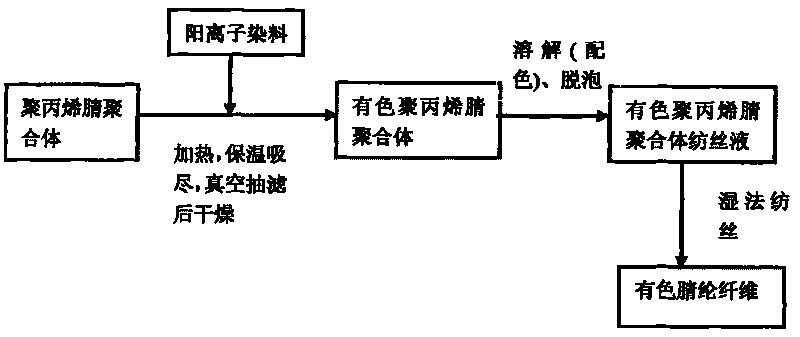

[0025] (1) Acrylic polymer dyeing

[0026] According to the standard GB2401-2006 "Determination method of fiber saturation value dye saturation value and saturation factor when cationic dyes dye acrylic fiber", find out the maximum dosage of each commercial dye for acrylic fiber polymer, mix powder polyacrylonitrile polymer with water, get Homogeneous mixture, according to the maximum dosage of each commercial dye to polyacrylonitrile, add the dye, the dyeing temperature is 98 ℃, the bath ratio is 1:50, the pH is 4-5, and the dye is dyed for 1h under the condition of full stirring. The exhaustion rate can reach 99.9%. After dyeing, the dye molecules in the water-soluble dye and the molecules of the polyacrylonitrile polymer are fully combined to obtain a suspension of the colored polyacrylonitrile polymer, and the excess in the colored polyacrylonitrile polymer suspension is removed by vacuum filtration. The moisture is removed, and it is fully dried at 110 °C.

[0027] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com