Dyeing and finishing technology for Hismer blended fabric

A blended fabric, dyeing and finishing technology, applied in the field of dyeing and finishing, can solve the problem of unable to complete the dyeing of Haysmore blended fabrics, and achieve the effect of good moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

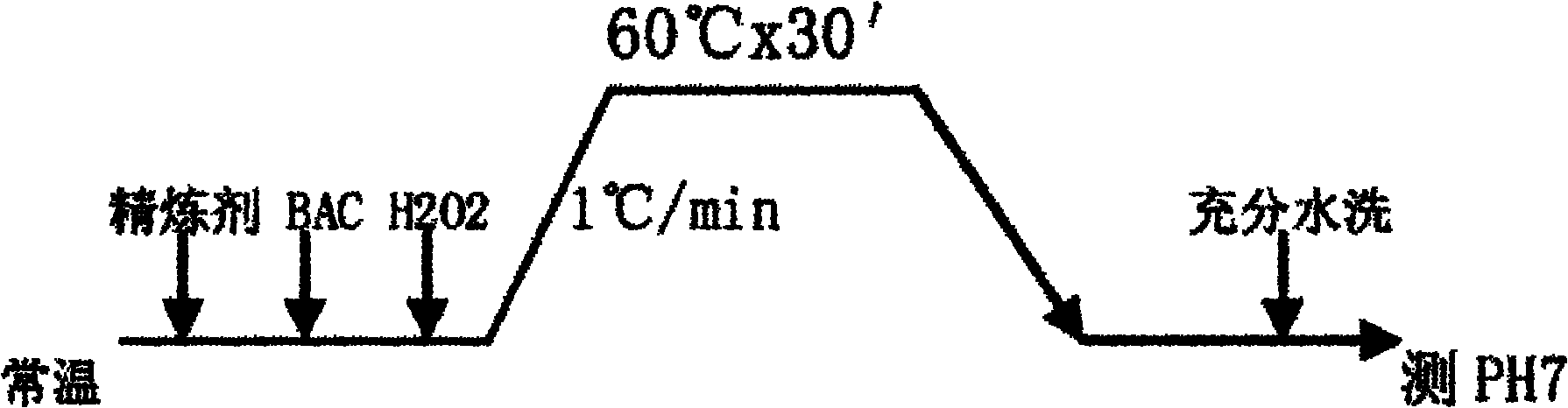

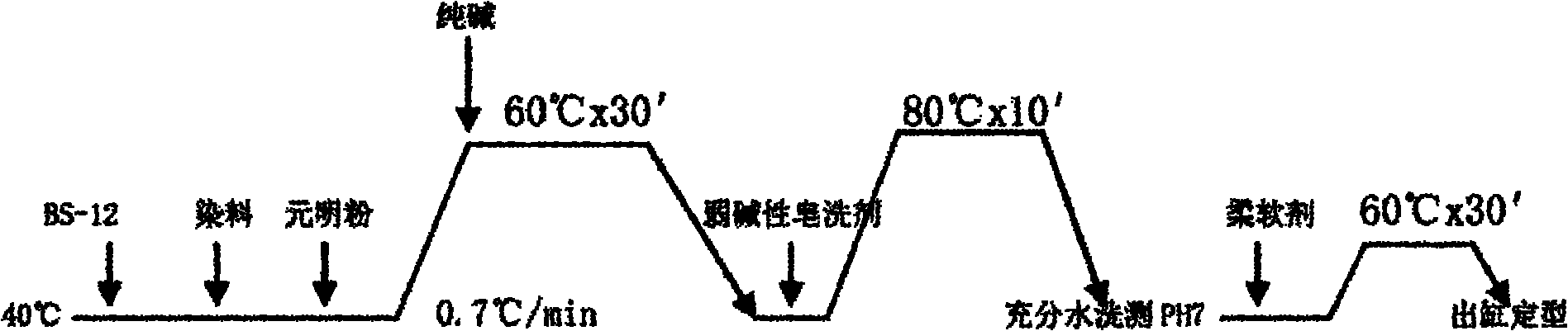

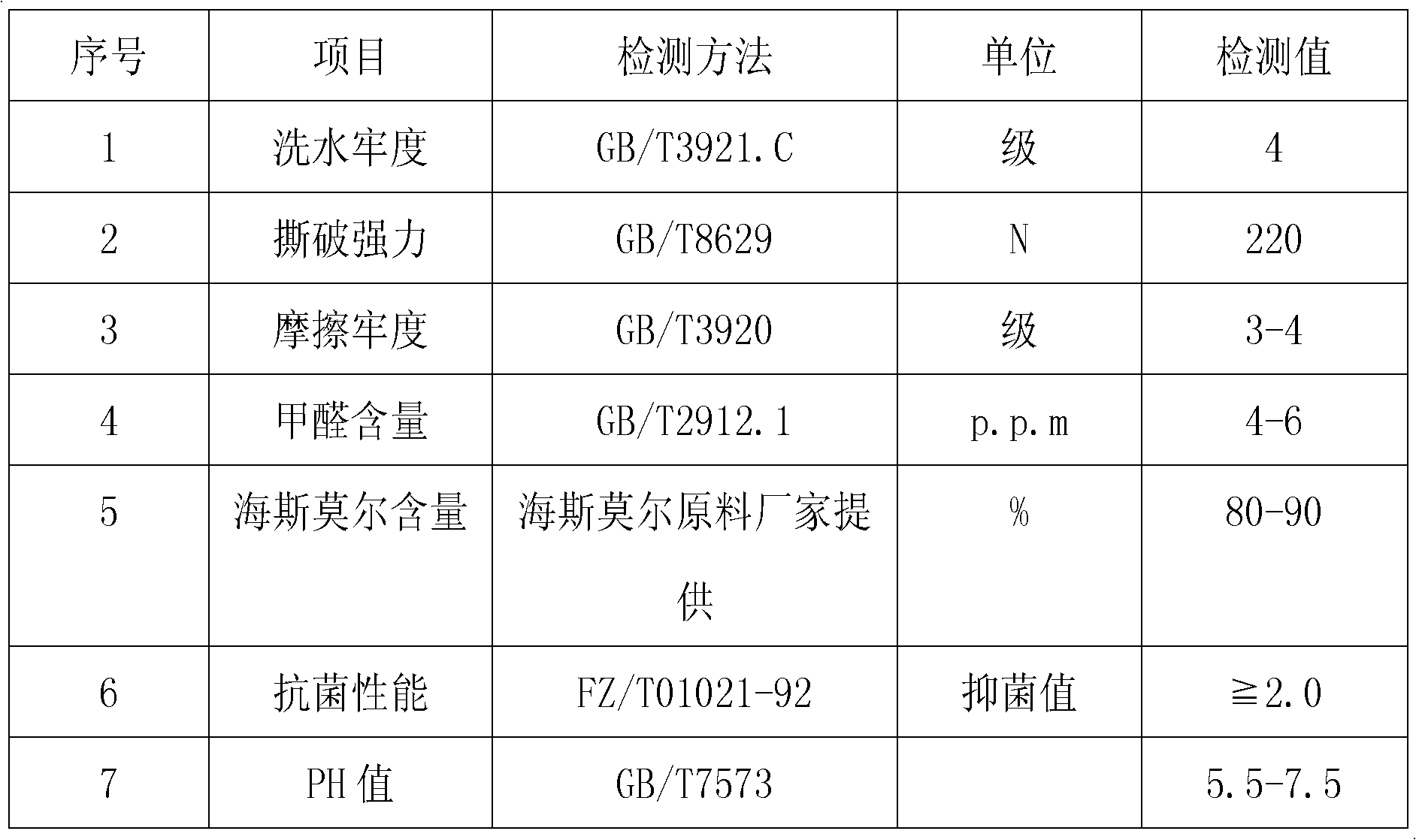

[0024] Such as figure 1 , figure 2 As shown, the dyeing and finishing technology of the Hessmore blended fabric described in this embodiment mainly includes a pretreatment process and a dyeing process, and is characterized in that:

[0025] a) Pre-treatment process: Put the Hessmore blended fabric into a mixed solution containing refining agent, anionic surfactant BAC and hydrogen peroxide and treat it at 60°C for 30 minutes, then fully wash it until the pH is PH7;

[0026] b) Dyeing process: before dyeing, first add amphoteric surfactant BS-12 into the dye bath at 40°C; then put the Hessmore blended fabric into the dye vat, slowly add vinylsulfone type reactive dyes and dyeing assistants in batches Then slowly heat up to 60°C at a heating rate of 0.7°C per minute. After reaching the specified temperature, add soda ash, use weak alkaline pH9-10, and keep the temperature at 60°C for 30 minutes to fix the color; after the color is fixed, add weak Alkaline soaping agent and ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com