Method for processing knitted composite fabric

A technology of composite fabrics and processing methods, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as easy peeling, fast coating aging, and untaught surface layer mass percentage, and achieve the effect of less process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

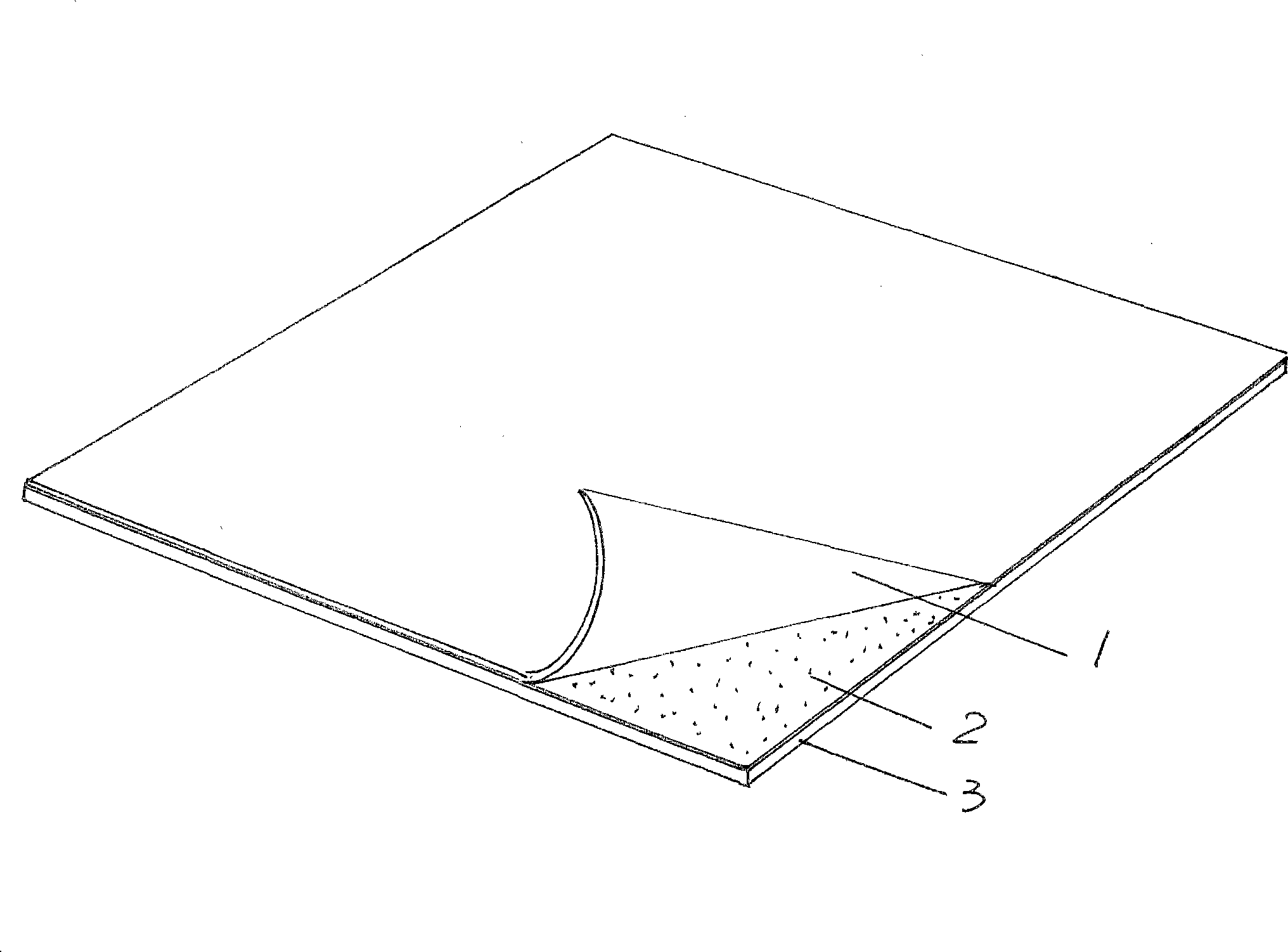

[0026] Please refer to the accompanying drawings, the knitted composite fabric shown in the figure is composed of a face cloth 1, a lining 3 and a thermoplastic polyurethane coating 2 coated on one side surface of the lining 3, wherein the face cloth 1 and the lining 3 are mutually Composite, so that the thermoplastic polyurethane coating 2 is located between the surface and the lining 1,3. This knitted composite fabric is obtained through the following processing steps.

[0027] A) Select the raw material of the face cloth and the raw material of the inner cloth, select the superfine denier polyester fiber of 75D / 144F and the spandex fiber (also known as 20D) produced and sold by the American Invista Corporation (which has been acquired by DuPont). Lycra) is used as the raw material of the face cloth, and the polyester fiber of 75D / 72F is selected as the raw material of the lining cloth, wherein: the superfine denier polyester fiber of 75D / 144F accounts for 83% of the mass pe...

Embodiment 2

[0034] The face cloth raw material in step A) is replaced with the superfine denier polyester fiber of 100D / 144F, and the mass percentage that accounts for in the face cloth raw material is 88%, and the mass percentage that spandex fiber accounts for in the face cloth raw material is 12 %;

[0035] Change the presetting temperature of the white gray fabric in step C) to 190°C, and change the cloth speed to 30m / min;

[0036] Change the adding amount of water-repellent agent into the rolling groove to 6% when the dyed face cloth is finalized in step D), change the adding amount of softening agent into 5%, and change the setting temperature and cloth speed of the setting machine into 170°C respectively. ℃, 30m / min, change the amount of Klein hygroscopic agent and clear water softener added to the rolling groove to 6% and 4% of the fabric weight when the dyed lining is set, and the setting temperature and cloth speed of the setting machine are respectively Change to 180°C and 35m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com