Dyeing technology for cotton cloth

A technology, a technology of cotton cloth, applied in the field of cotton dyeing technology, can solve the problems of unsatisfactory cotton cloth, easy color falling off, low color fastness, etc., and achieve the effect of improving color fastness, improving color fastness, and improving binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

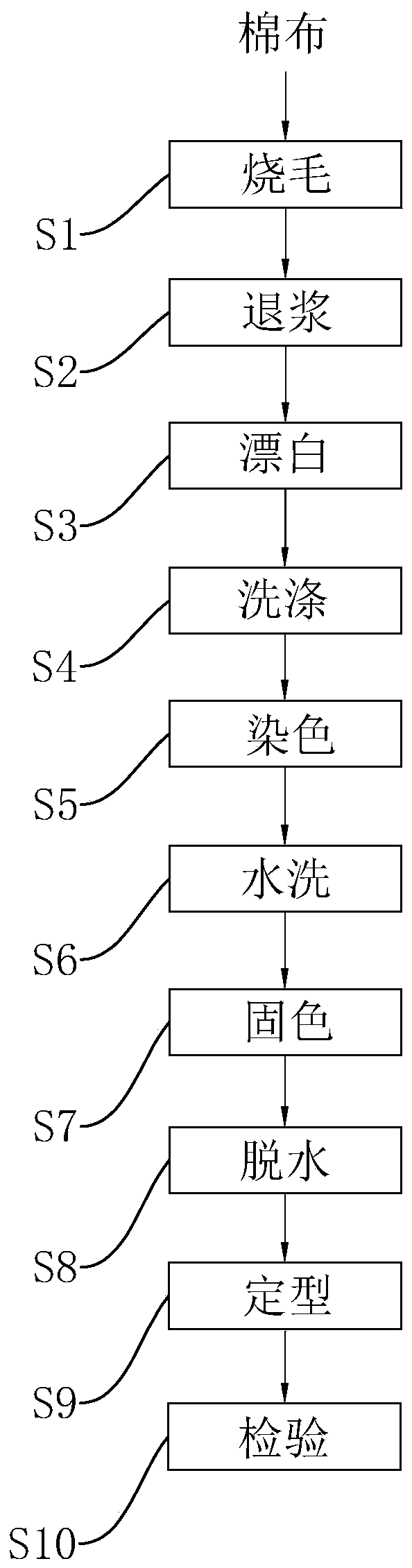

[0042] refer to figure 1, a dyeing process for cotton cloth, the following steps are carried out on the cotton grey cloth:

[0043] S1: singeing the grey cloth. The grey cloth is conveyed to the singeing machine for singeing, and the fluff and thread ends on the surface of the grey cloth are removed, so that the surface of the grey cloth is smooth and clean, and the dyeing defects caused by the existence of the fluff are prevented during dyeing.

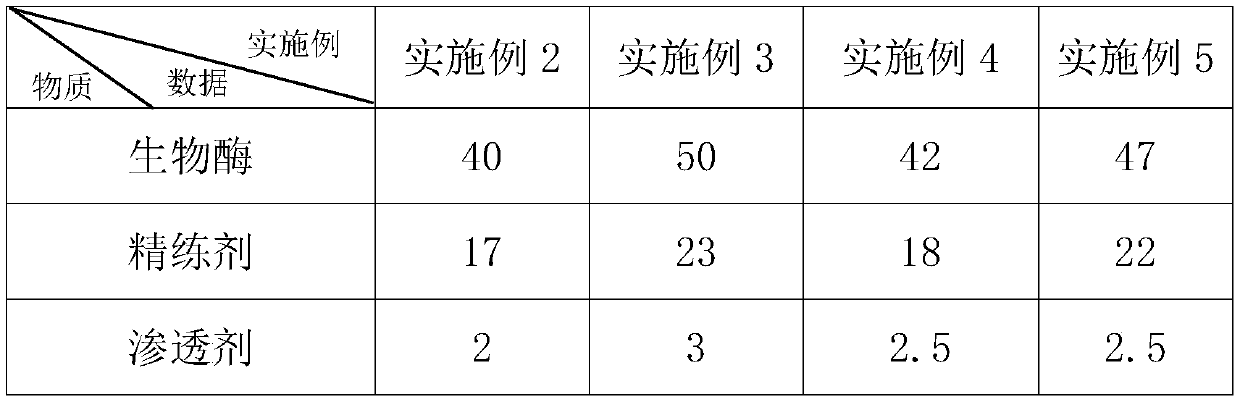

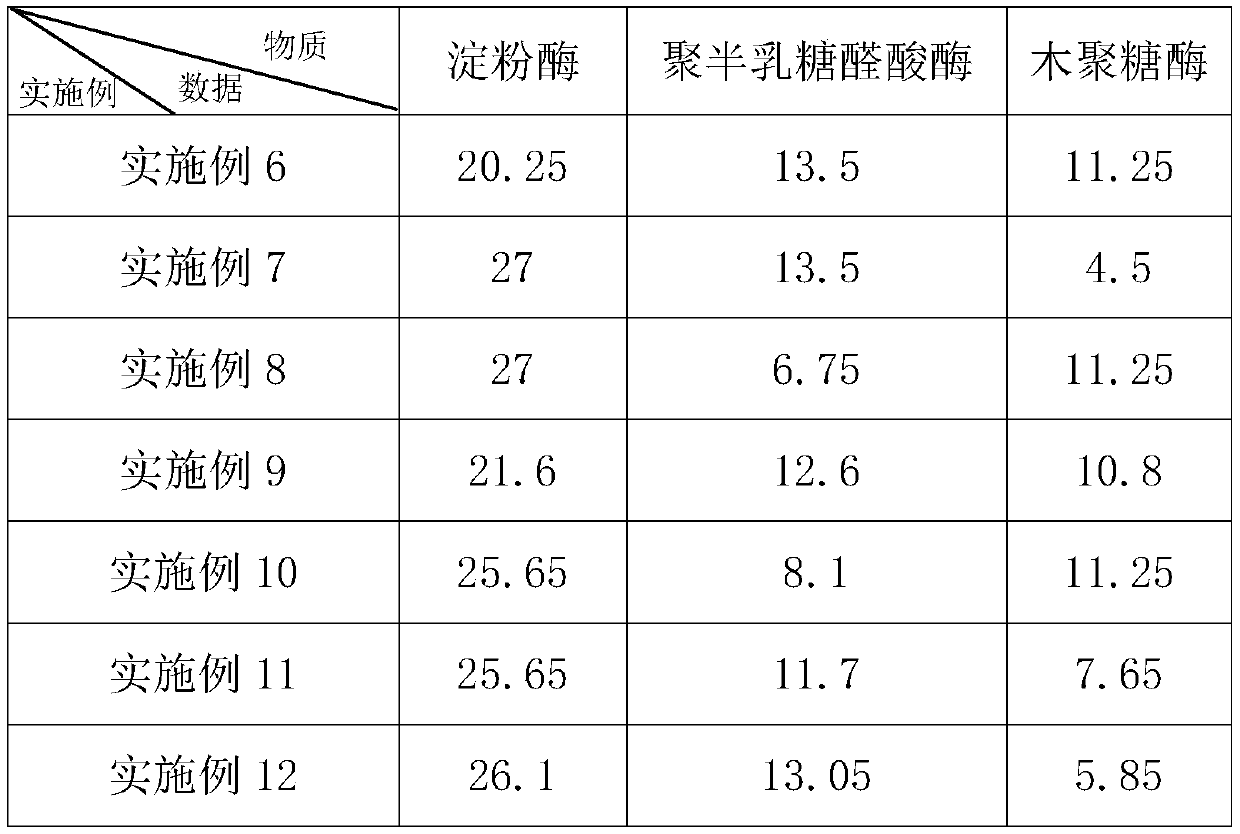

[0044] S2: Desizing. Desizing the singed grey fabric; first rinse the grey fabric with clean water, and after rinsing, transport the grey fabric to a desizing tank containing desizing solution for immersion for 90 minutes, and control the temperature of the desizing solution at 65°C during dipping, and the temperature of the desizing solution is 65°C. Each chemical composition is calculated in parts by weight: 45 parts of biological enzymes, 20 parts of scouring agents and 2.5 parts of penetrating agent, wherein the chemical compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com