Washing-free non-aqueous-solvent dyeing device and method adopting activated dye

A technology of reactive dyes and non-aqueous solvents, which can be used in dyeing methods, equipment configuration for processing textile materials, and containers for processing textile materials, etc., which can solve the problems of unsuitable dyeing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

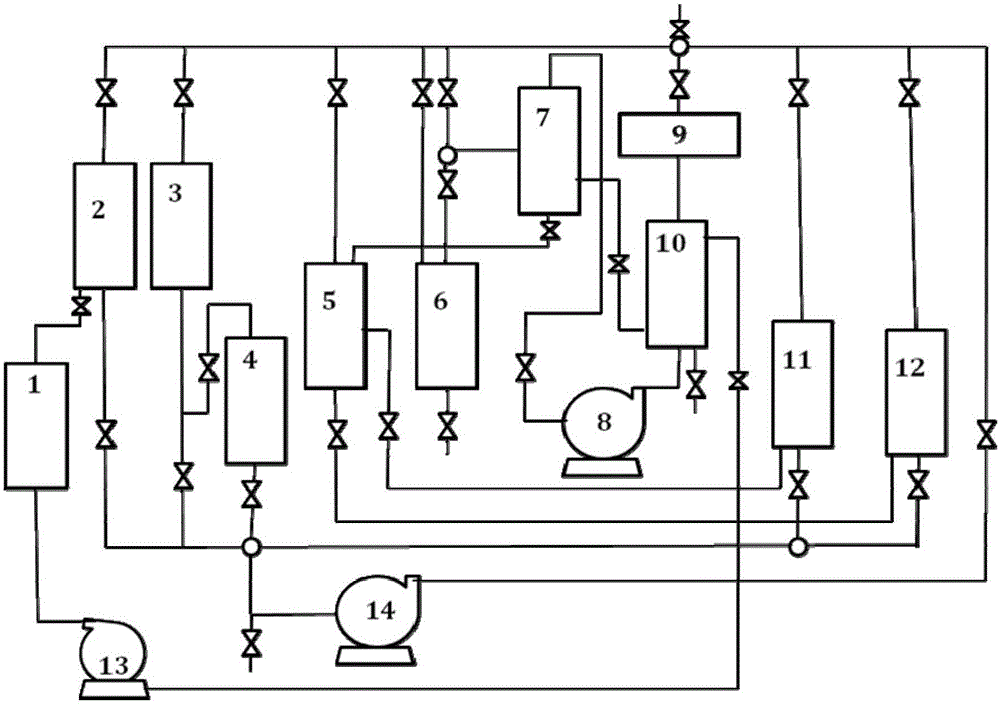

[0078] This embodiment provides a kind of non-aqueous solvent dyeing equipment of cotton cheese free-washing reactive dyes, such as figure 1 As shown, the dyeing equipment includes an auxiliary heating tube 1, a main dyeing vat 2, a chemical tank 3, a liquid storage tank 4, a liquid separator 5, a distillation tank 6, a condenser A7, a condenser B10, a vacuum pump 8, and an activated carbon box 9 , polar solvent storage tank 11, non-polar solvent storage tank 12, air pump 13 and main pump 14;

[0079] The main dye vat 2 is provided with a first feed port and a first discharge port, and the material tank 3 is provided with a second feed port and a second discharge port; the auxiliary heating pipe 1 is respectively connected with the main dye vat 2 and the air pump 13; the main dye vat The first feed port of 2 and the first discharge port are connected with the main pump 14 respectively, and the main dye vat 2 is also connected with the condenser A7; the second feed port and the...

Embodiment 2

[0096] This embodiment provides a non-aqueous solvent dyeing method for cotton cheese without washing reactive dyes, which uses the cotton cheese non-washing reactive dye non-aqueous solvent dyeing equipment provided in Example 1 to dye, comprising the following steps:

[0097] Place 700g of pure cotton cheese in a sodium carbonate solution with a concentration of 15g / L to swell at 90°C for 40min, then centrifugally dehydrate and dry with radio frequency;

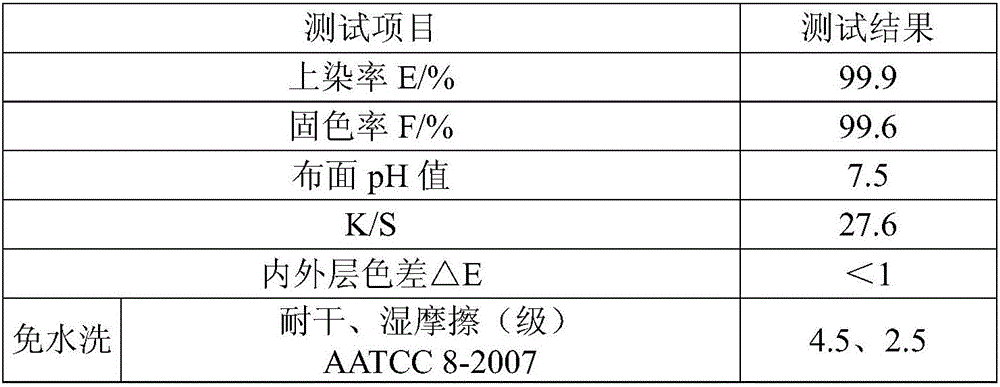

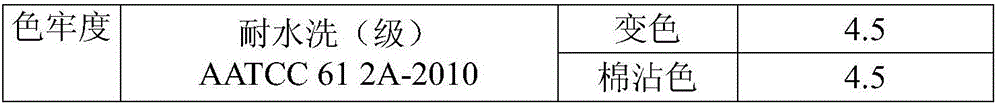

[0098] The cheese pre-swollen with sodium carbonate solution was placed in main dyeing vat 2, 21g (3% o.m.f) Avitera Blue SE dye, 12g potassium acetate, 10g benzyltriethylammonium bromide and 7g hexadecyl Add trimethylammonium chloride to material tank 3, then pump 2800mL of N,N-dimethylacetamide from polar solvent storage tank 11 into material tank 3, fully stir until evenly mixed, and then put the chemical material The solution in the tank is pumped into the main dyeing vat 2, dyeing at 35°C, and the temperature is slowly...

Embodiment 3

[0107] This embodiment provides a non-aqueous solvent dyeing method for cotton cheese without washing reactive dyes, which uses the cotton cheese non-washing reactive dye non-aqueous solvent dyeing equipment provided in Example 1 to dye, comprising the following steps:

[0108] Put 700g of pure cotton cheese into a potassium carbonate solution with a concentration of 12g / L to swell at 100°C for 30min, then centrifugally dehydrate and dry by radio frequency.

[0109] Place the cheese pre-swollen with potassium carbonate solution in the main dye vat 2, add 21g (3% o.m.f) Avitera Red SE dye, 15g sodium acetate and 23g dodecyltrimethylammonium chloride to the chemical material Groove 3, then pump the dimethyl sulfoxide of 2100mL into material tank 3 from polar solvent storage tank 11, fully stir to mix evenly, then pump the solution in the material tank into main dye vat 2, with 35 ℃ for dyeing, slowly heat up at a heating rate of 1°C / min, slowly pump 21,000 mL of decamethylcyclop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com