Cold-pad batch dyeing process for loose fibers

A technology for dyeing and dispersing fibers by cold pad stacking, which is applied in liquid/gas/vapor fiber/sliver/roving processing, textile processing machine accessories, textile material processing, etc. Loose fibers cannot be rolled and stacked to achieve the effect of overcoming uneven dyeing, ensuring uniform dyeing, and better and even leaching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

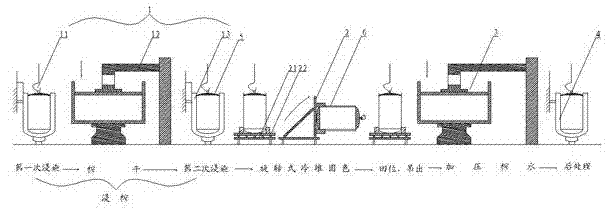

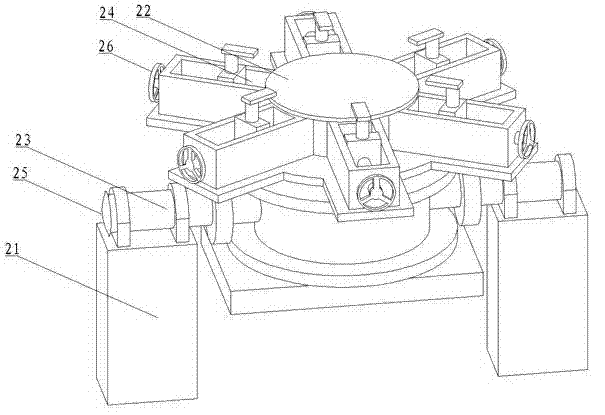

[0030] In the present embodiment, the cotton fiber is dyed special black, combined with figure 1 , the dyeing process of bulk fiber is: dipping (first dipping → drying → second dipping) → rotary cold stack → adding squeezed water → post-treatment, among which,

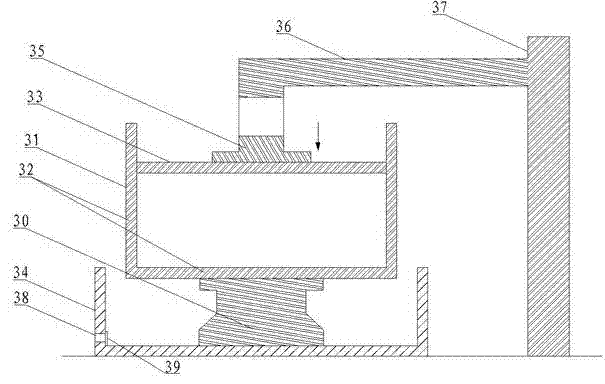

[0031] (1) Soaking: Put the loose fiber or loose fiber cake in the leaching device 1. The way of leaching is two immersion and one pressing to ensure that the loose fiber or loose fiber cake is absorbed evenly. The composition of the dyeing liquid is: H- ED reactive black 18g / L, 3RS yellow 2.2 g / L, 3BS red 3.0 g / L, NaOH 5 g / L, water glass 2.8 g / L, liquor ratio 1:4.5, dyeing at room temperature;

[0032]Wherein, two dipping and one squeezing include the first dipping, squeezing and second dipping carried out in sequence, the loose fiber or loose fiber cake is first dipped in the dye liquor of dipping device 11, and the first dipping The time is 10 minutes, and the first dipping plays the purpose of pretreatment, and th...

Embodiment 2

[0040] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that the loose fiber to be dyed is viscose fiber, and the viscose fiber is dyed bright red. Dry pressure is 1.8kg / cm 2 , the drying time is 5 minutes, and the second dipping time is 15 minutes. Among them, the conditions of the first dipping and the second dipping are the same, the bath ratio is 1:4.5, and the components of the dyeing solution: 3BS red 7.5 g / L, B-X Yuanqing 1.5 g / L, NaOH 2g / L, water glass 1 g / L, dyeing at room temperature; (2) Rotary cold pile: the rotating speed is 8r / min, the cold pile temperature is room temperature, and the cold pile processing time is 12 hours; (3) add squeezed water: the squeezed pressure is 2.8kg / cm 2 , The processing time is 8 minutes, the leak hole diameter is 3mm, and the opening rate is 70%.

Embodiment 3

[0042] The bulk fiber to be dyed in this embodiment is cotton fiber, and the dyed color is bright red. (1) Squeeze: the first dipping time is 30 minutes, and the drying pressure is 2 kg / cm 2 , the drying time is 5 minutes, and the second dipping time is 10 minutes, wherein, the liquor ratio of the first dipping and the second dipping is 1:4, and the components of the dyeing solution: 3BS red 7.5 g / L, B-X Yuanqing 1.5 g / L, NaOH 2g / L, water glass 1 g / L, dyeing at room temperature; (2) Rotary cold pile: the rotation speed is 15r / min, the cold pile temperature is room temperature, and the cold pile treatment time is 11 hours; (3) Add squeeze water: squeeze pressure is 1.5kg / cm 2 , The processing time is 15 minutes, the leak hole diameter is 2mm, and the opening rate is 50%. The rest of the settings and working principles are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com