Production process of colored viscose filament yarns

A technology of viscose filament and production process, which is applied in the production of colored viscose filament, the production process of viscose filament, and the production process of colored viscose filament, which can solve the problem of inability to carry out large-scale production and increase environmental protection. Cost, narrow scope of application and other issues, to achieve the effect of broadening color varieties, avoiding loss and pollution, and broadening the application market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

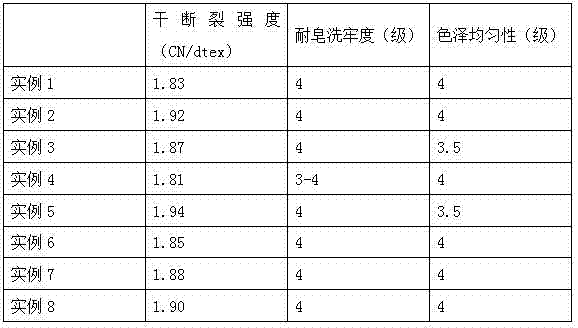

Examples

Embodiment 1

[0028] A production process for colored viscose filaments, comprising the following process steps:

[0029] A. Color paste preparation:

[0030] Prepare 10% of the reduced date red 2R aqueous solution, stir evenly, and obtain the color slurry;

[0031] B. Preparation of colored viscose:

[0032] Mix the color paste liquid prepared in step A into the dissolving barrel after yellowing in proportion, and the mass percentage of dyestuff and methyl cellulose in the colored viscose after mixing is 2%;

[0033] C. Spinning and dyeing:

[0034] After the mixed colored viscose is produced according to the ordinary viscose filament production process, after filtration and defoaming, it is pumped into the spinning machine by the glue supply pump for 120D / 30F spinning and forming. The raw silk strips coming out of the acid bath are passed through the air bath and The deacidified water containing 1 gram / liter of hydrogen peroxide is oxidized to make the color show the original color and...

Embodiment 2

[0036] A production process for colored viscose filaments, comprising the following process steps:

[0037] A. Color paste preparation:

[0038] Weigh SU-08 sulfur bright green (sulfur green 14), add it to the sodium hydroxide solution, the mass concentration of the sodium hydroxide solution is 6%, stir evenly to obtain the color slurry, the total mass concentration of the dye in the color slurry is 5%;

[0039] B. Preparation of colored viscose:

[0040] Mix the prepared color slurry solution in step A into a filtered intermediate barrel in proportion, and the mass percentage of dyestuff and methyl cellulose in the mixed colored viscose is 0.8%;

[0041] C. Spinning and dyeing:

[0042] After the mixed colored viscose is produced according to the ordinary viscose filament production process, after filtration and defoaming, it is pumped into the spinning machine by the glue supply pump for 300D / 50F spinning and forming, and the raw silk strips coming out of the acid bath ar...

Embodiment 3

[0044] A production process for colored viscose filaments, comprising the following process steps:

[0045] A. Color paste preparation:

[0046] Take vat yellow G and join in the sodium hydroxide solution, the mass concentration of the sodium hydroxide solution is 3%, stir evenly, obtain the color paste liquid, the total mass concentration of the dyestuff in the color paste liquid is 7%;

[0047] B. Preparation of colored viscose:

[0048] Mix the prepared color paste in step A in proportion to the intermediate barrel after the second filter, and the mass percentage of dyestuff and methyl cellulose in the mixed colored viscose is 1.5%;

[0049] C. Spinning and dyeing:

[0050]After the mixed colored viscose is produced according to the ordinary viscose filament production process, after filtration and defoaming, it is pumped into the spinning machine by the glue supply pump for 150D / 30F spinning and forming. The raw silk strips coming out of the acid bath are passed through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com