Method for producing dye through textile waste materials to dye fabric

A technology for dyeing textile waste and fabrics, which is applied in the field of textile printing and dyeing, can solve the problems of increasing secondary pollution, reducing product yield, and lack of affinity, and achieves the effects of reducing pollution, reducing dosage, and realizing recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This implementation provides a kind of method that utilizes textile waste to produce dyestuff to fabric dyeing, and this method comprises the following steps:

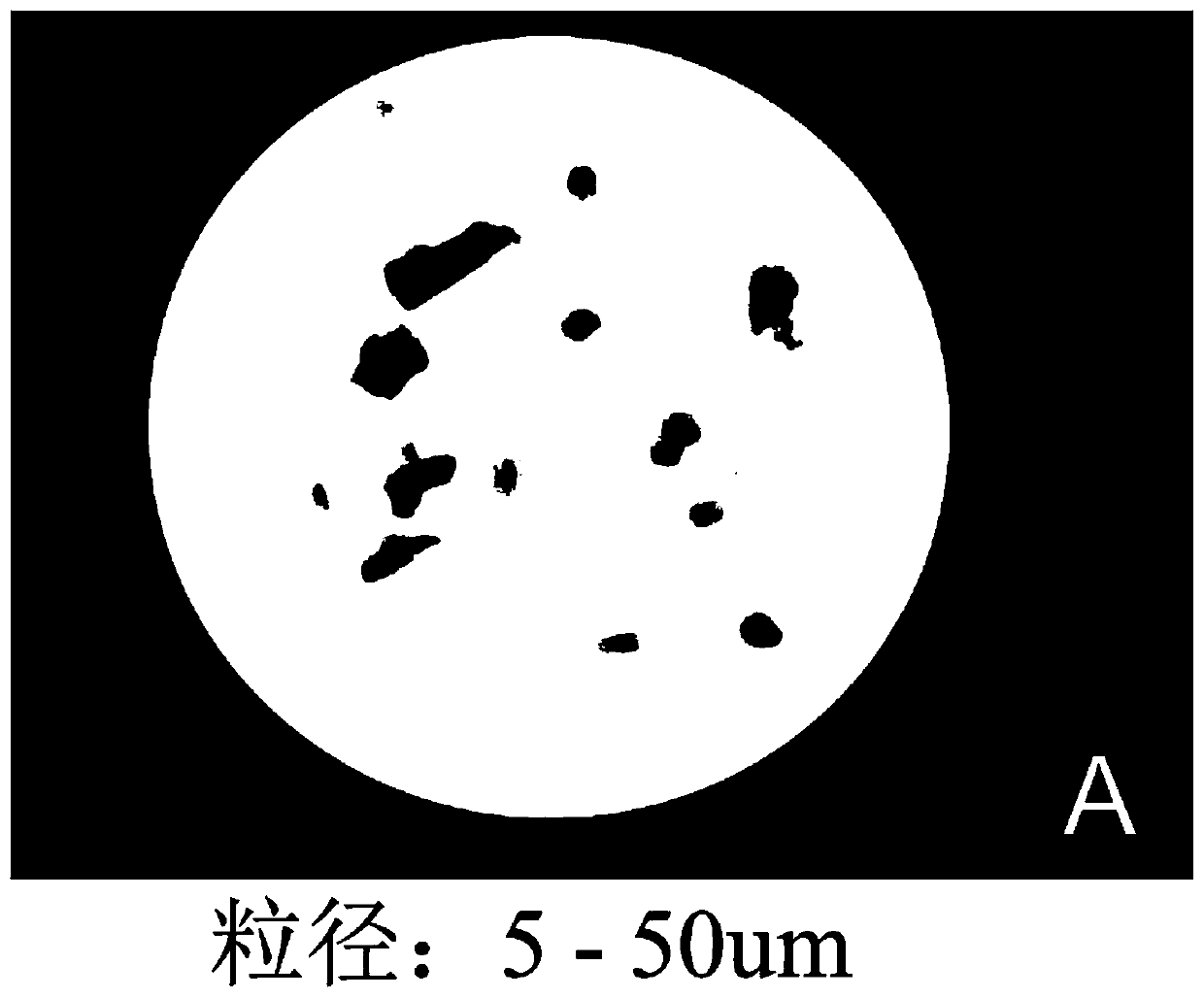

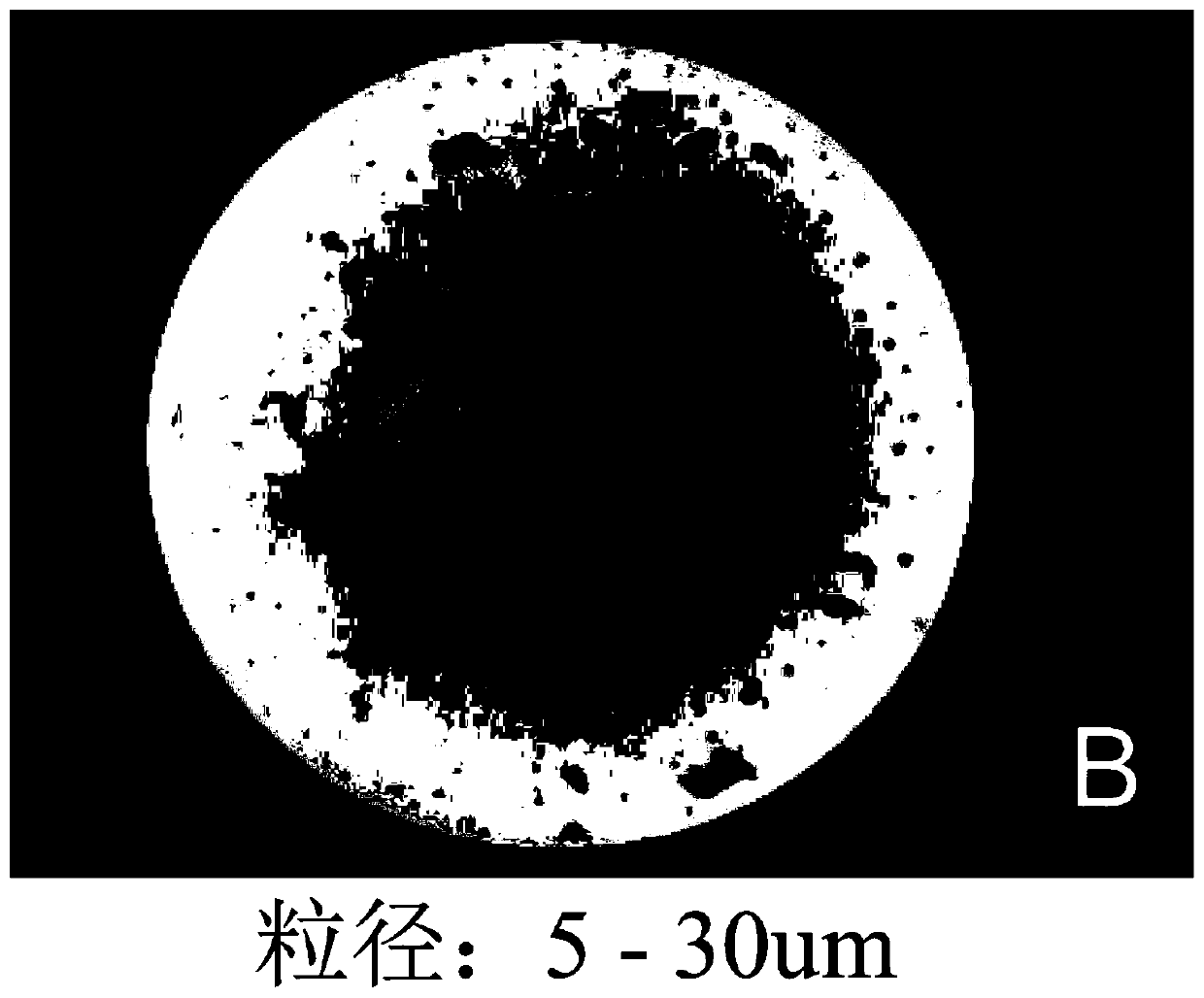

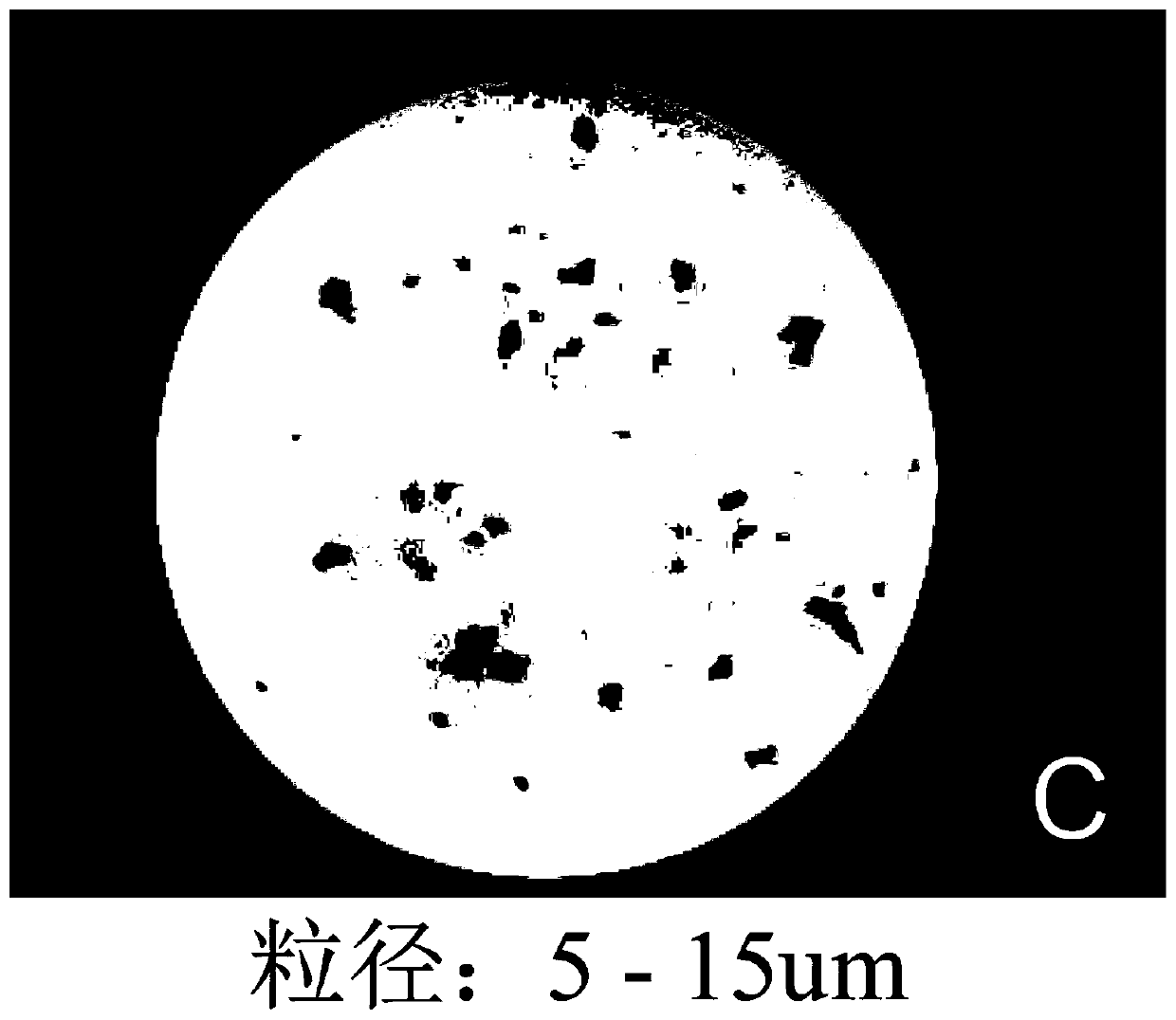

[0057] Step 1: Coarsely pulverize the dyed red cotton fabric discarded in the production process of the factory, and then efficiently grind the coarsely pulverized red cotton fabric with a shock grinder. The grinding frequency is 2800 times / min, and the grinding time is 5 minutes. , and sieve the fiber powder to obtain effective fiber powder with a particle size of 30-60 μm. Such as Figure 1A , Figure 1B and Figure 1C as shown, Figure 1A : Grinding for 3min (x400), particle size: 5-50um; Figure 1B : Grinding for 5min (x400), particle size: 5-30um; Figure 1C : Grinding for 10min (x400), particle size: 5-15um.

[0058] Step 2, using the anionic treatment agent carboxypolyethylene glycol to anionize the fabric, the amount of carboxypolyethylene glycol is 0.3g / L, and the bath ratio is controlled at 1:20; t...

Embodiment 2

[0067] This implementation provides a kind of method that utilizes textile waste to produce dyestuff to fabric dyeing, and this method comprises the following steps:

[0068] Step 1: Coarsely pulverize the dyed yellow cotton fabric discarded during the production process of the factory, and then efficiently grind the coarsely pulverized yellow cotton fabric with a shock-type grinder. The grinding frequency is 3200 times / min, and the grinding time is 5 minutes. , and sieve the fiber powder to obtain effective fiber powder with a particle size of 15-50 μm.

[0069] Step 2, using the anion treatment agent carboxypolyethylene glycol to anionize the fabric, the amount of carboxypolyethylene glycol is 0.5g / L, and the bath ratio is controlled at 1:30; the temperature of the anionization treatment is 60°C, and the treatment The time is 10 minutes;

[0070] Then use the cationic treatment agent polyamide resin aqueous solution to carry out cationic treatment on the anionized fabric, t...

Embodiment 3

[0078] This implementation provides a kind of method that utilizes textile waste to produce dyestuff to fabric dyeing, and this method comprises the following steps:

[0079] Step 1: Coarsely pulverize the dyed blue cotton fabric discarded in the production process of the factory, and then efficiently grind the coarsely pulverized blue cotton fabric with a shock grinder at a grinding frequency of 3600 times / min. After 5 minutes, the fiber powder is sieved to obtain an effective fiber powder with a particle size of 5-30 μm.

[0080] Step 2, using the anionic treatment agent carboxypolyethylene glycol to anionize the fabric, the amount of carboxypolyethylene glycol is 0.5g / L, and the bath ratio is controlled at 1:40; the temperature of the anionization treatment is 60°C, and the treatment The time is 10 minutes;

[0081] Then utilize cationic treatment agent nitrogen heterocyclic cationic compound (Suzhou Hengwang Chemical Co., Ltd. HW-168B) to carry out cationic treatment to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com