Cold-pad batch dyeing process of loose fibers

A technology of cold pad pile dyeing and loose fibers, applied in the field of loose fiber dyeing, can solve the problems of unsatisfactory combination of dyes and loose fibers, easy fading of loose fibers, and high process cost, so as to overcome uneven distribution of dye liquor and increase dye uptake. The effect of efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

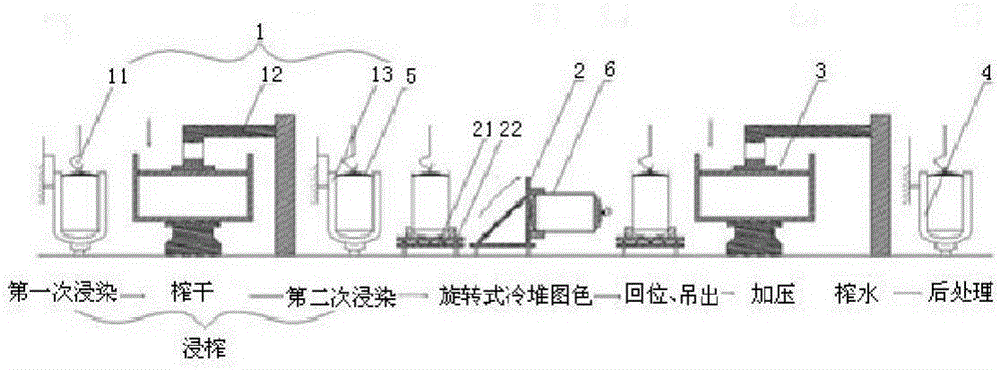

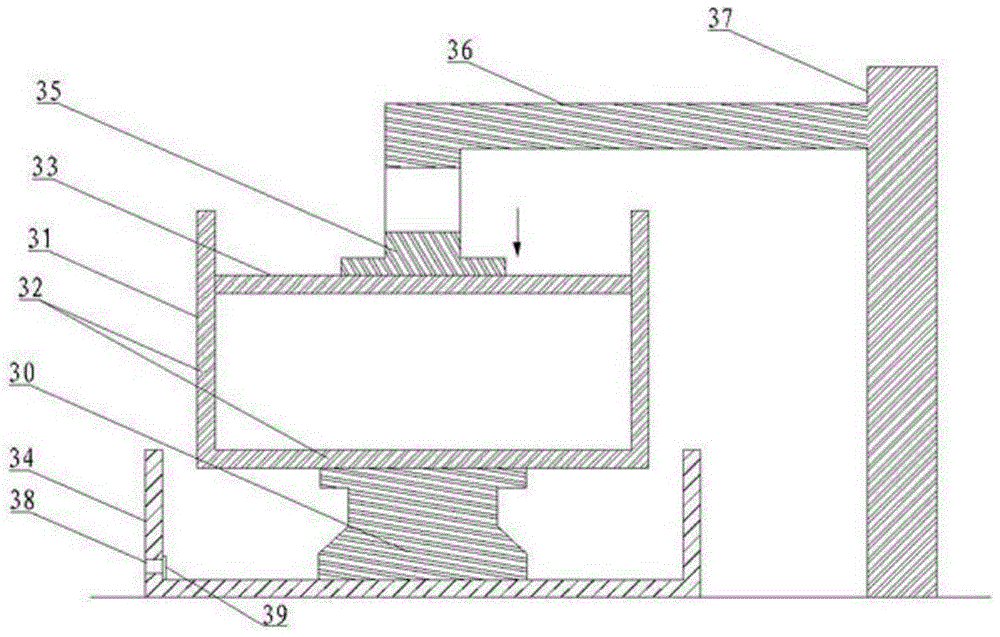

[0038] In this embodiment, cotton fibers are dyed black, and the dyeing process of loose fibers is: ultrasonic dyeing→rotary cold stack→pressurized water→post-treatment, wherein

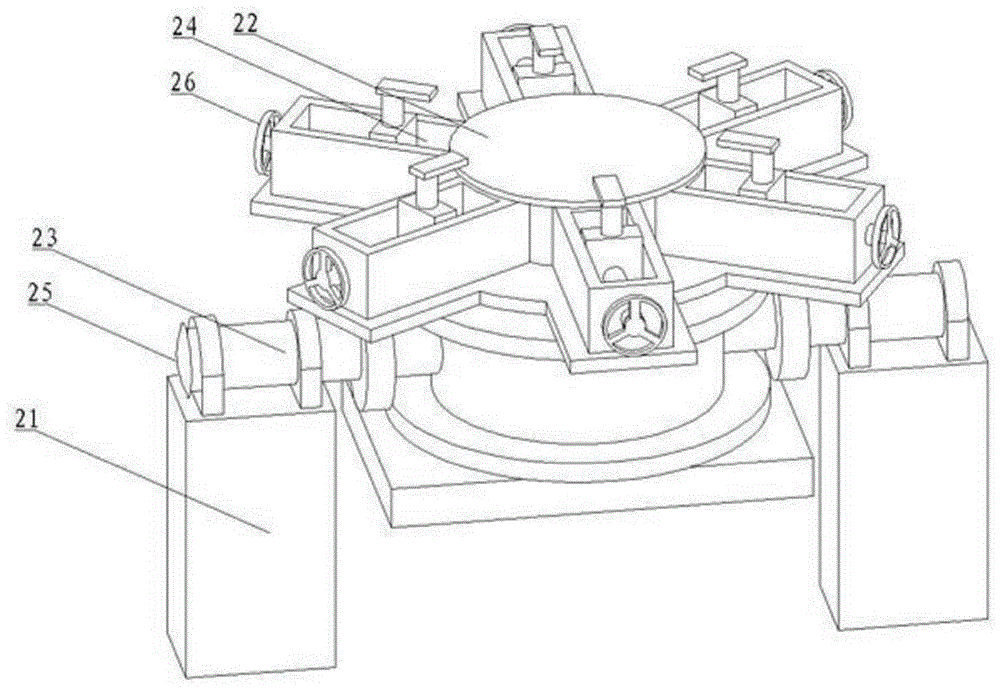

[0039] (1) Ultrasonic dyeing: put the prepared dye into the ultrasonic dyer and heat up to 65°C, turn on the ultrasonic wave, set the frequency at 35Hz and heat up to 95°C at a rate of 0.5°C / min, then add carboxylated carbon nanospheres and leveling agent and stirred at a speed of 30r / s for 50min, wherein the mass ratio of carboxylated carbon nanospheres to dyestuffs was 0.007:1, and the mass ratio of leveling agent to dyestuffs was 0.04:1, and was put into loose fibers for dyeing for 3.5h; (2) Rotary cold stack: place the impregnated bulk fiber or loose fiber cake in a horizontal state, and conduct a rotary cold stack in a sealed environment with a rotation speed of 10r / min and a cold stack temperature of room temperature (20-25°C ), the cold stack processing time is 10 hours; wherein, the rotary co...

Embodiment 2

[0044] (1) Ultrasonic dyeing: In addition to putting the prepared dye in an ultrasonic dyer and heating it up to 60°C, ultrasonically, set the frequency at 30Hz and raise the temperature to 90°C at a rate of 0.5°C / min, and stir at a rate of 20r / s 60min, the mass ratio of carboxylated carbon nanospheres and dyestuff is 0.005:1, the mass ratio of leveling agent and dyestuff is 0.03:1, put into loose fiber dyeing 3h, other steps are identical with step (1) in embodiment 1 .

[0045] (2) Rotary cold pile: except that the rotating speed is 5r / min, the cold pile temperature is room temperature (20-25° C.), and the cold pile treatment time is 12 hours, other steps are the same as step (2) in Example 1.

[0046] (3) and (4) are all the same as steps (3) and (4) in Example 1.

Embodiment 3

[0048] (1) Ultrasonic dyeing: In addition to putting the prepared dye in an ultrasonic dyer and heating it up to 70°C, ultrasonically, set the frequency at 40Hz and raise the temperature to 100°C at a rate of 0.5°C / min, and stir at a rate of 40r / s 40min, the mass ratio of carboxylated carbon nanospheres and dyestuff is 0.01:1, the mass ratio of leveling agent and dyestuff is 0.06:1, put into loose fiber dyeing 4h, other steps are identical with step (1) in embodiment 1 .

[0049] (2) Rotary cold pile: except that the rotating speed is 15r / min, the cold pile temperature is room temperature (20-25° C.), and the cold pile treatment time is 10 hours, other steps are the same as step (2) in Example 1.

[0050] (3) and (4) are all the same as steps (3) and (4) in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com