Yilun printed fabric and its printing method

A printing method, Yilun's technology, applied in the textile field, can solve the problems of not being able to reach customers, poor high-temperature ironing fastness of garments, and lighter colors, etc., achieve high printing color fastness and color depth, and meet the high-end needs of the market , pattern realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A printing method for Yilun fabric, the steps are as follows:

[0058] 1. Use 100D Benbai Yilun embryo yarn to weave required gray fabric.

[0059] Among them, D (denier) is an expression method of the fineness of chemical fibers, which refers to the weight in grams of 9000-meter-long fibers at a given moisture regain.

[0060] 2. Arrange the above blanks in the pretreatment solution for padding, two dipping and two rolling, after taking out, dry at 130°C for use.

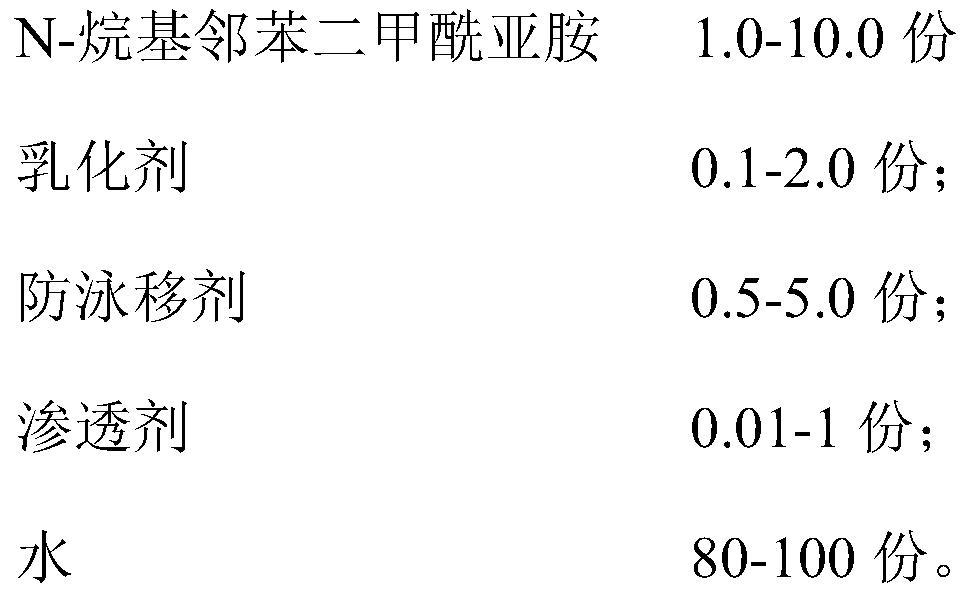

[0061] The components of the pretreatment liquid are as follows (in parts by weight):

[0062]

[0063] 3. Use Epson thermal sublimation ink (High Density Black T742X, Yellow T7424, Magenta7423, Cyan T7422) to print the target pattern on the thermal sublimation transfer paper, and then transfer the target pattern from the thermal sublimation printing paper to the dry After the gray cloth.

[0064] The process parameters of the transfer printing are as follows: the temperature is 160° C., the pressure i...

Embodiment 2

[0077] A printing method for Yilun fabric, the steps are as follows:

[0078] 1. Use 100D Benbai Yilun embryo yarn to weave required gray fabric.

[0079] Among them, D (denier) is an expression method of the fineness of chemical fibers, which refers to the weight in grams of 9000-meter-long fibers at a given moisture regain.

[0080] 2. Arrange the above blanks in the pretreatment solution for padding, two dipping and two rolling, after taking out, dry at 100°C for use.

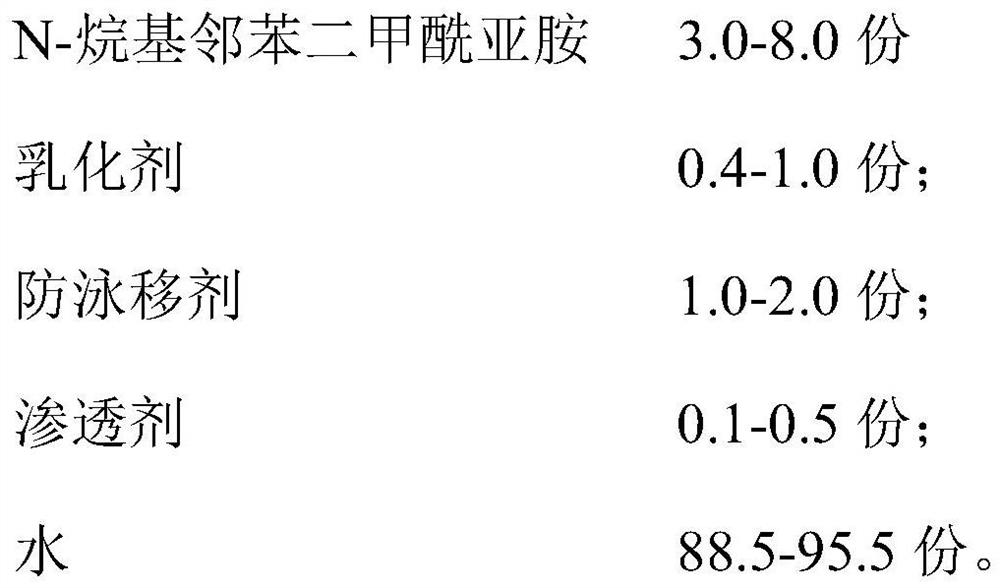

[0081] The components of the pretreatment liquid are as follows (in parts by weight):

[0082]

[0083] 3. Use Epson thermal sublimation ink (High Density Black T742X, Yellow T7424, Magenta7423, Cyan T7422) to print the target pattern on the thermal sublimation transfer paper, and then transfer the target pattern from the thermal sublimation printing paper to the dry After the gray cloth.

[0084] The process parameters of the transfer printing are as follows: the temperature is 160° C., the pressure i...

Embodiment 3

[0097] A printing method for Yilun fabric, the steps are as follows:

[0098] 1. Use 100D Benbai Yilun embryo yarn to weave required gray fabric.

[0099] Among them, D (denier) is an expression method of the fineness of chemical fibers, which refers to the weight in grams of 9000-meter-long fibers at a given moisture regain.

[0100] 2. Arrange the above blanks in the pretreatment solution for padding, two dipping and two rolling, after taking out, dry at 150°C for use.

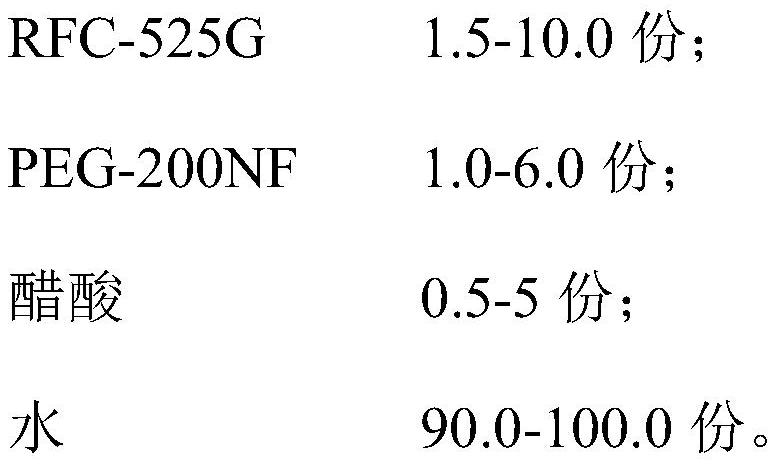

[0101] The components of the pretreatment liquid are as follows (in parts by weight):

[0102]

[0103] 3. Use Epson thermal sublimation ink (High Density Black T742X, Yellow T7424, Magenta7423, Cyan T7422) to print the target pattern on the thermal sublimation transfer paper, and then transfer the target pattern from the thermal sublimation printing paper to the dry After the gray cloth.

[0104] The process parameters of the transfer printing are as follows: the temperature is 170° C., the pressure i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com