A device and method for measuring explosion vent distance of pipe gallery

A technique of measuring device and measuring method, which is applied in the field of gas explosions in narrow and long spaces, to achieve the effects of reducing explosion hazards, satisfying explosion venting safety, and reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

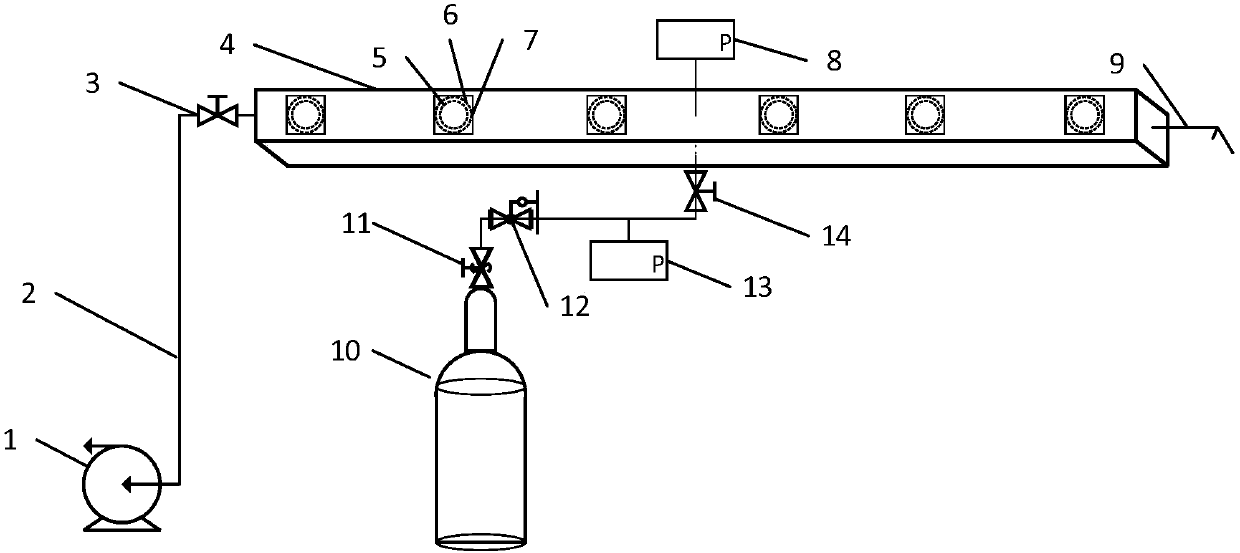

[0018] A device for measuring the explosion vent distance of a pipe gallery, including a vacuum pump 1, a knob valve 3, a pipe gallery 4, an explosion vent 5, a manhole cover 6, a heavy pressure object 7, a pressure gauge 8, an igniter 9, a gas storage cylinder 10, and a knob valve 11. Pressure reducing valve 12, pressure gauge 13 and knob valve 14; vacuum pump 1 is connected to knob valve 3, the other end of knob valve 3 is connected to pipe gallery 4, and the opening of explosion vent 5 is provided on pipe gallery 4 , the pipe gallery 4 is also provided with a manhole cover 6 and a heavy pressure object 7, and the manhole cover 6 covers the explosion vent 5; there is a first pressure gauge 8 and an igniter 9 on the pipe gallery 4, and a knob valve 11 is arranged on the gas storage cylinder 10 in sequence , a pressure reducing valve 12 and a second pressure gauge 13, and the gas cylinder 10 is connected to the pipe gallery 4 through a knob valve 14.

[0019] In the above embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com