A kind of degreasing and leveling compound emulsifier and its application

A compound emulsifier, degreasing dyeing technology, applied in the direction of dyeing, textile and papermaking, etc., can solve the problems of color light, dyeing uniformity, high temperature dispersibility of dyes, influence on production quality, etc., to achieve good degreasing function, reduce Wastewater pollution, the effect of shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0032] Raw material formula of the present invention carries out batching according to table 1, and unit is: kilogram

[0033] Table 1 raw material formula

[0034]

[0035] The preparation process of the present invention is: the selected pentaerythritol polyoxyethylene polyoxypropylene fatty acid ester, fatty diol terephthalate, biomass surfactant and maleic acid di-sec-octyl sodium sulfonate Mix evenly to obtain the oil-removing and leveling compound emulsifier of the present invention.

[0036] The beneficial effects that the degreasing and leveling compound emulsifier of the present invention has:

[0037] 1. It has good surface activity and has excellent emulsifying and dispersing effect on the oil agent on the fabric.

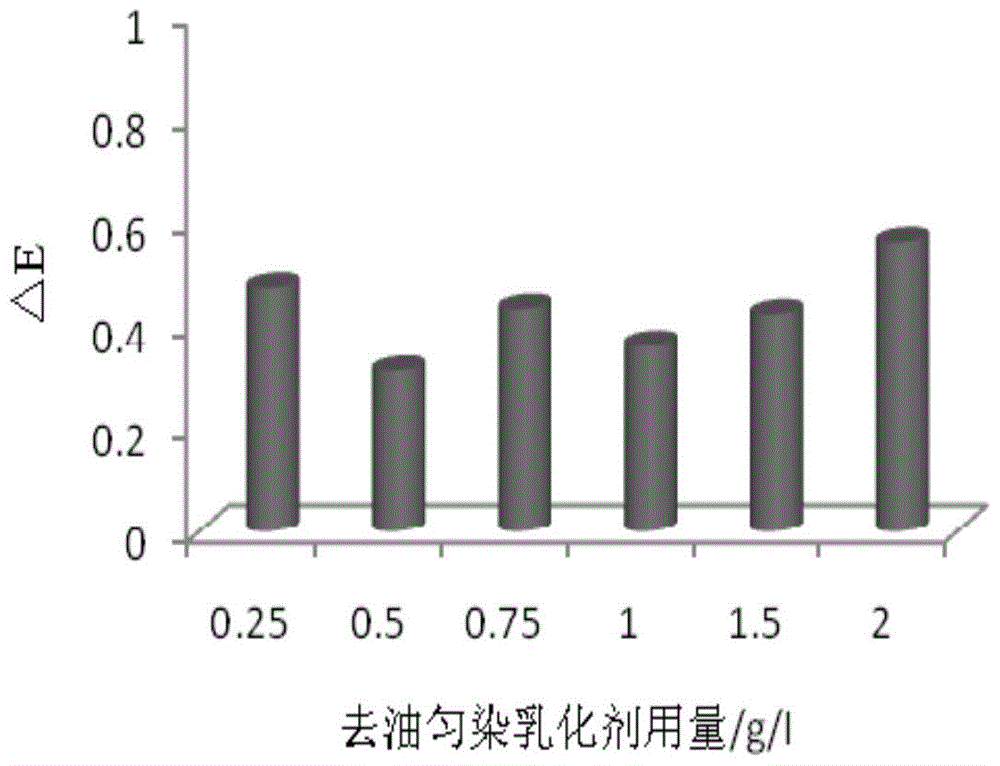

[0038] 2. It has good dye dispersibility, dye migration and dye uptake rate, has little effect on fabric shade, and can improve the success rate and reproducibility of dyeing at one time. Its migration, dye uptake rate and shade influence are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com