All-around brightener for denim fabric as well as preparation method and application of all-around brightener

A technology for denim fabrics and brighteners, used in textiles and papermaking, improved hand-feel fibers, spray/jet textile material processing, etc., can solve hand and gloss defects, single formula, and denim brighteners are difficult to obtain to meet market requirements and other problems, to achieve the effect of improved feel and gloss, easy to use and fluffy feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

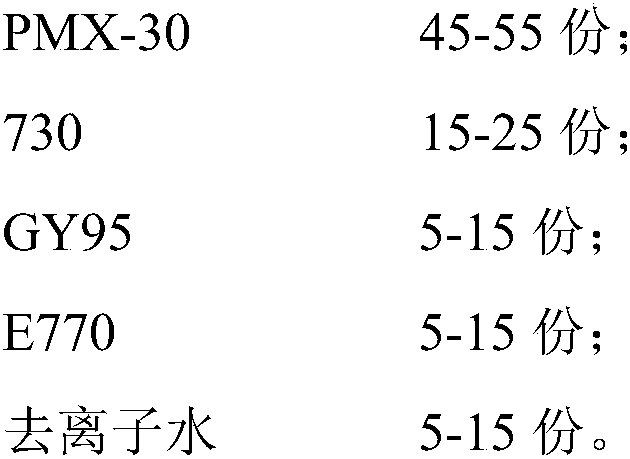

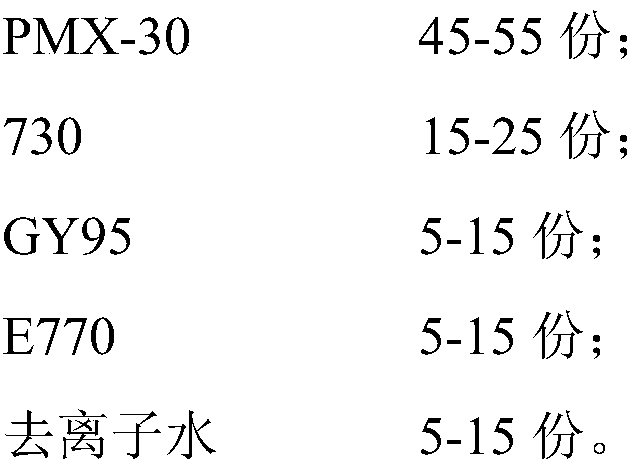

[0020] A kind of all-purpose brightener preparation method is as follows:

[0021] (1) Preparation of PMX-30:

[0022] In parts by weight, put 19 parts of TMN-6 and 1 part of TMN-3 into the reaction tank, control the temperature in the tank at 50°C, control the speed at 100r / min, and stir for 10 minutes. Put 30 parts of PMX-200 into the reaction tank, control the speed at 1000r / min, and stir for 10min. Then 50 parts of deionized water was slowly added into the reaction kettle while stirring. After adding water, continue to stir at high speed for 30 minutes to obtain milky white PMX-30.

[0023] (2) Preparation of 730:

[0024] In parts by weight, 6 parts of 1308 and 4 parts of 1305 were added into the tank, the temperature inside the tank was controlled at 60°C, and the rotation speed was controlled at 50 r / min. Add 30 parts of ternary copolymerization block silicone oil (897) into the reaction tank, control the rotation speed at 120r / min, and stir for 20min. Then add 0.1...

Embodiment 2

[0028] A method for preparing an all-purpose brightener, comprising the steps of:

[0029] (1) Preparation of PMX-30:

[0030] According to parts by weight, 10 parts of TMN-6 and 2 parts of TMN-3 were stirred and reacted at 45°C for 15 minutes, and the speed was controlled at 120r / min; then 25 parts of PMX-200 were put into the reaction for 15 minutes, and the speed was controlled at 1200r / min; Slowly add 45 parts of deionized water to the reaction system while stirring; after adding the water, continue to stir at high speed (1200r / min) for 25 minutes to prepare milky white PMX-30.

[0031] Both TMN-6 and TMN-3 are emulsifiers; the PMX-200 is simethicone with a viscosity of 350cs.

[0032] (2) Preparation of 730:

[0033] In parts by weight, 2 parts of isotridecyl alcohol polyoxyethylene ether 1308 and 6 parts of isomeric tridecyl alcohol polyoxyethylene ether 1305 were stirred at 55°C for 10 minutes, the speed was controlled at 40r / min, and 40 parts of block silicone oil 89...

Embodiment 3

[0037] A method for preparing an all-purpose brightener, comprising the steps of:

[0038] (1) Preparation of PMX-30:

[0039] According to parts by weight, 20 parts of TMN-6 and 0.5 parts of TMN-3 were stirred and reacted at 55°C for 5 minutes, and the speed was controlled at 120r / min; then 35 parts of PMX-200 were stirred and reacted for 5 minutes, and the speed was controlled at 1200r / min; Slowly add 55 parts of deionized water to the reaction system while stirring; after adding the water, continue to stir at high speed (1200r / min) for 35 minutes to obtain milky white PMX-30.

[0040] Both TMN-6 and TMN-3 are emulsifiers; the PMX-200 is simethicone with a viscosity of 350cs.

[0041] (2) Preparation of 730:

[0042]In parts by weight, 10 parts of isotridecyl alcohol polyoxyethylene ether 1308 and 2 parts of isomeric tridecyl alcohol polyoxyethylene ether 1305 were stirred at 65 ° C for 10 minutes, and the speed was controlled at 60 r / min. 25 parts of block silicone oil 89...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com