Stain-resistant anti-slip agent for wood floor plate and preparation method thereof

A kind of anti-slip agent technology for wood floors, which is applied to biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the problems of anti-slip agents such as cracking or shrinkage, achieve long-lasting anti-slip effects, and have mild preparation conditions , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of oxidized polyethylene wax emulsion in the application, by weight, at least comprises the following steps:

[0036] (1) Weigh 30 parts of oxidized polyethylene wax and add to 60 parts of solvent toluene, then add a certain amount of graphene oxide dispersion and 0.15-3 parts of acid catalyst. Heating and reflux for 4-8 hours, the rotation speed is 1000rpm, and the distilled water is received by a water receiver. The catalyst is recovered by filtration, the solvent is recovered by a rotary evaporator, and the oxidized polyethylene wax modified by graphene oxide is obtained by drying.

[0037] (2) the above-mentioned graphene oxide modified oxidized polyethylene wax obtained above, 6 parts of fatty alcohol polyoxyethylene ethers, and 1 part of sorbitan monostearate are put into a three-necked flask and heated;

[0038] (3) Stir after the above components are completely melted, at a speed of 800-1000 rpm, and stir for 30 minutes;

[0039] (4) Add...

Embodiment approach

[0070] As a preferred embodiment, the polycarboxylate ammonium salt (model: SN-5027) is purchased from Japan Nopco Corporation.

[0071] As a preferred embodiment, the polyacrylate is hydroxyl polyacrylate.

[0072] Polyacrylate

[0073] In this application, polyacrylates improve flow and leveling, providing a smooth, smooth and pleasing anti-slip agent. In addition, while providing leveling, it can also play a wetting role, without affecting the bonding force between the anti-slip agent and the floor, and polluting the environment. However, due to the limited compatibility with the polymer solution, pure acrylate cannot play a good leveling effect.

[0074] The anti-slip agent of the present application is added with hydroxyl polyacrylate, which has certain compatibility with polymer emulsion. At the same time, due to the polarity of the hydroxyl group, the process of migrating to the surface of the anti-slip agent can effectively take away water vapor, eliminate the for...

Embodiment 1

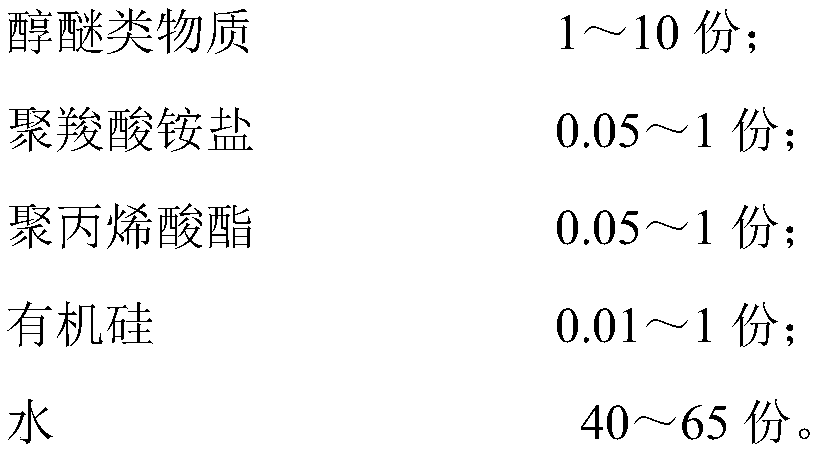

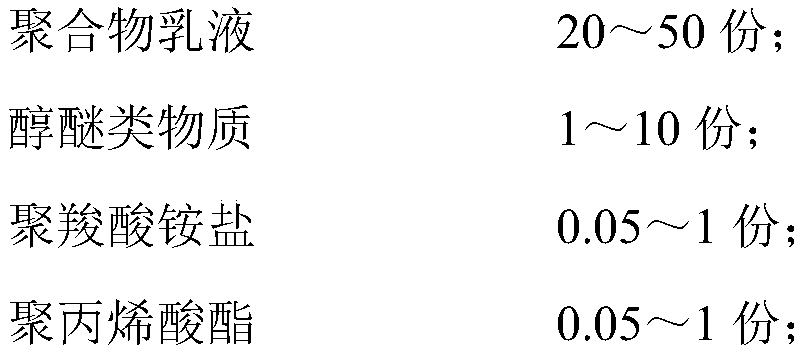

[0097] Embodiment 1 provides a kind of anti-slip agent for wooden floor, by weight, comprising the following components:

[0098]

[0099] Wherein, the polymer emulsion is composed of 10% by weight of oxidized polyethylene wax emulsion and 90% of acrylic acid emulsion.

[0100] The weight percentage of graphene oxide in the oxidized polyethylene wax emulsion is 0.1%, the sheet diameter of graphene oxide is 50-200 nm, and the thickness is 0.8-1.2 nm.

[0101] The weight percent of graphene oxide in the acrylic emulsion is 0.8%, the sheet diameter of graphene oxide is 50-200nm, and the thickness is 0.8-1.2nm.

[0102] The alcohol ethers are dipropylene glycol methyl ether.

[0103] The polycarboxylate ammonium salt (model: SN-5027) was purchased from Japan Nopco Corporation.

[0104] The polyacrylate is a hydroxyl polyacrylate, and the hydroxyl value of the hydroxyl polyacrylate is 40 mgKOH g -1 .

[0105] The organosilicon (model: TCB-1)) was purchased from Foshan Nanhai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com