UV (ultraviolet) glue water, polyurethane acrylate oligomer and preparation method of polyurethane acrylate oligomer

A polyurethane acrylate, oligomer technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc. The effect of high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

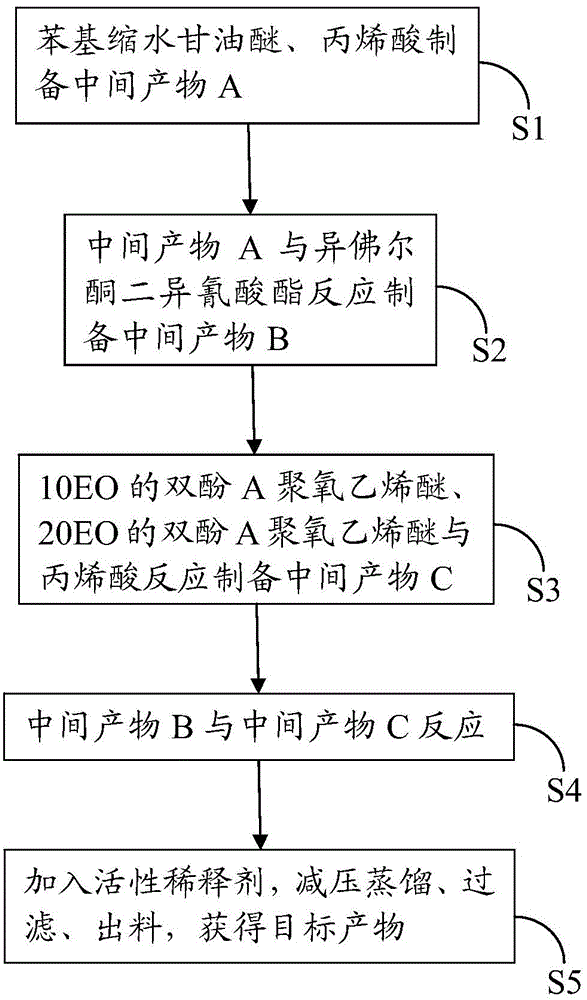

[0029] Such as figure 1 Shown, the present invention discloses a kind of preparation method of polyurethane acrylate oligomer, and it comprises the steps:

[0030] Step S1. Add phenyl glycidyl ether and acrylic acid to the first reactor at a molar ratio of 1:1 to 1:1.05, then add a polymerization inhibitor and a catalyst to the first reactor, and obtain an intermediate product A after reaction. Preferably, the molar ratio of phenyl glycidyl ether and acrylic acid is 1:1.01˜1:1.03, and the optimum molar ratio of phenyl glycidyl ether and acrylic acid is 1:1.01.

[0031] Wherein, in the S1, the temperature in the first reactor is increased to 95-120°C, preferably 100-108°C, and the optimum value is 105°C. Under this temperature condition, the reaction is carried out for 3-7 hours, preferably 4-5 hours. When the acid value of the system in the first reactor is less than 4 mgKOH / g, the reaction is stopped to obtain the intermediate product A.

[0032] The mass fraction of the po...

Embodiment 1

[0048] Add 30g of phenylglycidyl ether, 14.54g of acrylic acid, 0.3g of tetramethylammonium bromide, and 0.0223g of inhibitor 4-methoxyphenol into the reactor, heat up to 100°C under stirring, and react for about 5 hours. When the acid value of the system in the reactor was 2 mgKOH / g, the reaction was stopped to obtain an intermediate substance A.

[0049] After the temperature of the system in the reactor drops to 60°C, add 44.4g of isophorone diisocyanate and 60g of toluene, stir evenly, then add 3 drops of dibutyltin dilaurate to it, and react for 1.5h. When the -NCO group content of the system in the reactor drops to half of the initial value, the reaction is stopped to obtain the intermediate product B.

[0050] 100.2g bisphenol A polyoxyethylene ether (10EO), 55.4g bisphenol A polyoxyethylene ether (20EO), 1.8g p-toluenesulfonic acid, 0.08g inhibitor 4-methoxyphenol, 0.5g sub Phosphoric acid and 130g toluene were mixed in another reactor. Then add 14.4g of acrylic acid...

Embodiment 2

[0053] Add 30g of phenylglycidyl ether, 14.54g of acrylic acid, 0.25g of tetraethylammonium bromide, 0.0223g of polymerization inhibitor 2,6-di-tert-butyl p-cresol into the reactor, heat up to 108°C under stirring, and react About 4.5h. When the acid value of the system in the reactor was 1.6 mgKOH / g, the reaction was stopped to obtain intermediate product A.

[0054] After the temperature of the system drops to 55°C, add 44.4g of isophorone diisocyanate and 60g of toluene, stir evenly, then add 3 drops of dibutyltin dilaurate to it, and react for 1.5h. When the -NCO group content of the system in the reactor drops to half of the initial value, the reaction is stopped to obtain the intermediate product B.

[0055] 80.16g bisphenol A polyoxyethylene ether (10EO), 88.64g bisphenol A polyoxyethylene ether (20EO), 2.0g p-toluenesulfonic acid, 0.09g inhibitor 2,6-di-tert-butyl p-cresol , 0.5g hypophosphorous acid and 130g toluene were mixed in another reactor. Then add 14.4g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com