A kind of preparation method and application of multifunctional ultraviolet absorber

A multifunctional, absorbent technology, applied in fiber type, organic chemistry, fiber treatment, etc., to achieve high dye uptake, good antistatic properties, and good anti-ultraviolet effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

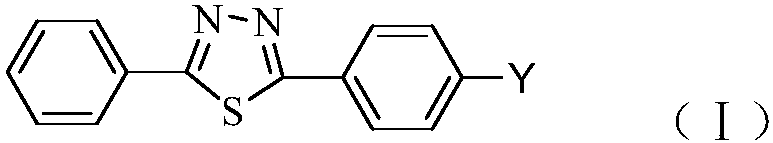

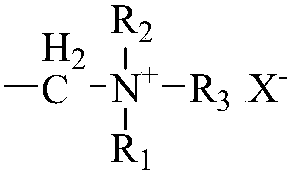

[0039] preparation of

[0040] synthetic route:

[0041]

[0042] Intermediate 1: Synthesis of methyl 4-methoxybenzoate

[0043] Add 80.00g (0.53mol) of 4-methoxybenzoic acid, 107.3ml of methanol, and 10.7ml of concentrated sulfuric acid into a 250ml round bottom flask, install a spherical condenser, heat to reflux, and control the temperature of the oil bath at 90°C React for 4 hours. Slowly pour the solution into ice water equipped with electromagnetic stirring while it is hot, and stir while adding, a white solid precipitates out immediately. Cool, filter with suction, use dilute Na 2 CO 3 The solution was washed until slightly alkaline, then washed with water until neutral, and air-dried in a fume hood to obtain a white ester-like product with a yield of 95%.

[0044] Intermediate 2: Synthesis of 4-methoxybenzohydrazide

[0045] Add 53.15g (0.32mol) methyl 4-methoxybenzoate to a 500ml round bottom flask, reflux 300ml 50% hydrazine hydrate for 4 hours, replace th...

Embodiment 2

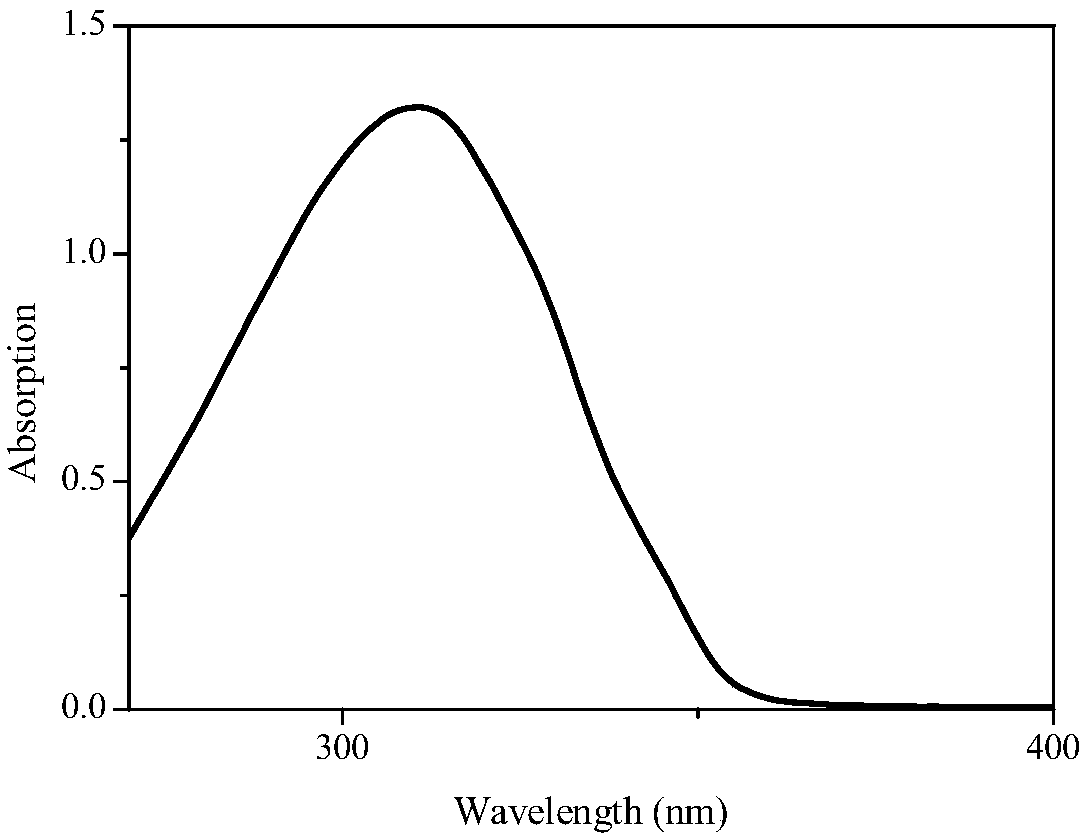

[0062] This embodiment is a research on the ultraviolet absorption performance, antibacterial and antistatic performance of the ultraviolet absorber 8, including determining the optimized finishing process, the test structure of ultraviolet absorption performance, antibacterial performance, and antistatic performance test results.

[0063] The test of fabric ultraviolet protection factor UPF: according to the standard of GB / T18830-2002, it is carried out on UV-1000F fabric ultraviolet transmittance analyzer.

[0064] Antibacterial performance test: Quantitative test is carried out with reference to the oscillation method in Appendix D8 of the antibacterial knitwear industry standard FZ / T73023-2006, and the test bacteria are: Gram-positive bacteria - Staphylococcus aureus (ATCC6538) and Gram-negative bacteria - Escherichia coli (ATCC8099).

[0065] Determination of surface specific resistance of the fabric: after placing the tested fabric in an environment of 20°C and a relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com