Method for improving color fastness of polyester cotton

A color fastness, polyester-cotton technology, applied in the direction of dyeing, textiles and papermaking, can solve the problems of large fabric wear and increase cost, improve production efficiency, improve washing fastness and color fastness, omit reduction cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Take dyed 32S / 100D navy blue blow cloth as an example:

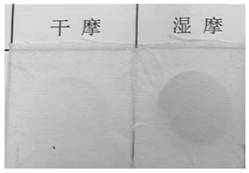

[0022] Dyeing process: high-temperature dyeing machine 130 ℃ fixed washing, soaping color fastness test after the cloth is out, using new additives, soaping color fastness test after the cloth is set, compared with the former, see the finalized Effect.

[0023]

[0024]

[0025] S1. Use the commonly used dyeing machine for knitted fabrics (ECO-8-D1T Fong’s Dyeing and Finishing Machinery Co., Ltd.) to dye in water at a liquor ratio of 1:10, and accelerate the high-temperature leveling agent and acetic acid into the dyeing machine at a constant speed;

[0026] S2. Load the cloth, adjust the cloth speed to about 200m / min, and adjust the pump pressure to make the spray volume of the nozzle 80% of the maximum;

[0027] S3. Dyeing and washing: raise the temperature of the dyeing machine by 40°C, add the disperse dyes into the slurry into the dyeing machine through the chemical tank, raise the temperature to 80°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com