Manufacturing method of compressor piston and compressor piston

A manufacturing method and compressor technology, which is applied in the field of compressors, can solve the problems of high cost and increased cost, and achieve the effects of improving surface hardness, improving wear resistance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

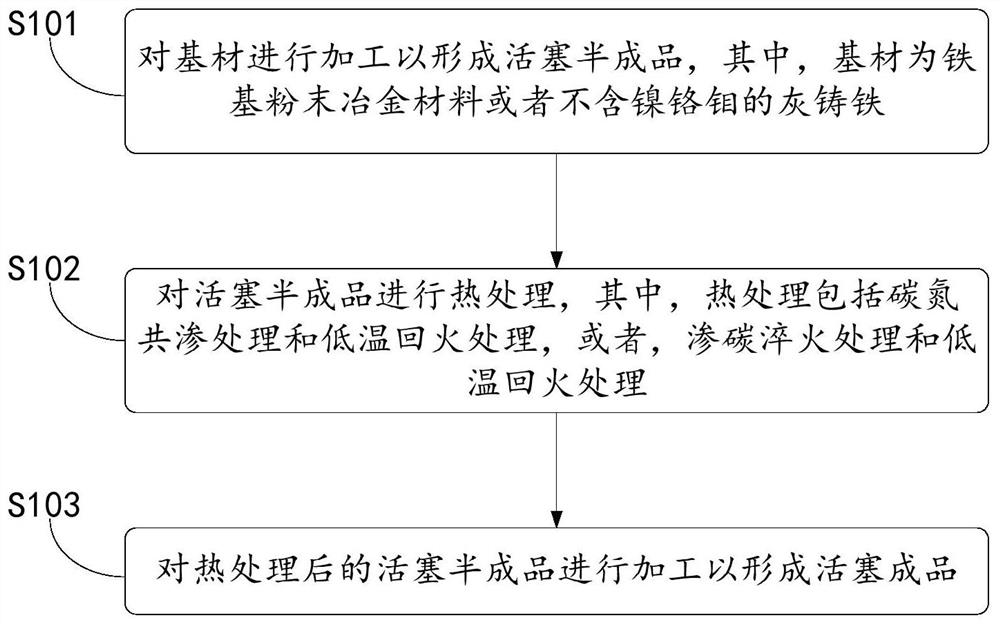

Method used

Image

Examples

Embodiment 1

[0041] First, the gray cast iron casting with the grade HT250 is roughly machined to form a semi-finished piston; then the semi-finished piston is subjected to carbonitriding / carburizing and quenching treatment, and the treatment temperature for carbonitriding / carburizing and quenching is 900°C , the carbon potential is 1.1%, and the carburizing time is 4 hours; then the semi-finished piston is tempered at a low temperature, the holding temperature is 200°C, and the holding time is 3 hours; finally, the semi-finished piston is finished after heat treatment to form The finished piston, at this time, the surface hardness of the finished piston is 50±3HRc.

Embodiment 2

[0043] First, the iron-based powder metallurgy material is directly sintered into a piston semi-finished product through a grinding tool. The chemical composition (weight %) of the iron-based powder metallurgy is as follows: C0.8%, Cu1.6%, Fe balance, and the density of the pressed piston semi-finished product 7.1cm 2 / g; Carry out carbonitriding treatment / carburizing quenching treatment to this piston semi-finished product then, the treatment temperature of carbonitriding treatment / carburizing quenching treatment is 880 ℃, carbon potential is 1.1%, and carburizing time is 4 hours; Then the semi-finished piston is subjected to low-temperature tempering treatment, the holding temperature is 200°C, and the holding time is 3 hours; finally, the semi-finished piston that has been heat-treated is processed to form a finished piston. At this time, the surface hardness of the finished piston is 50±3HRc .

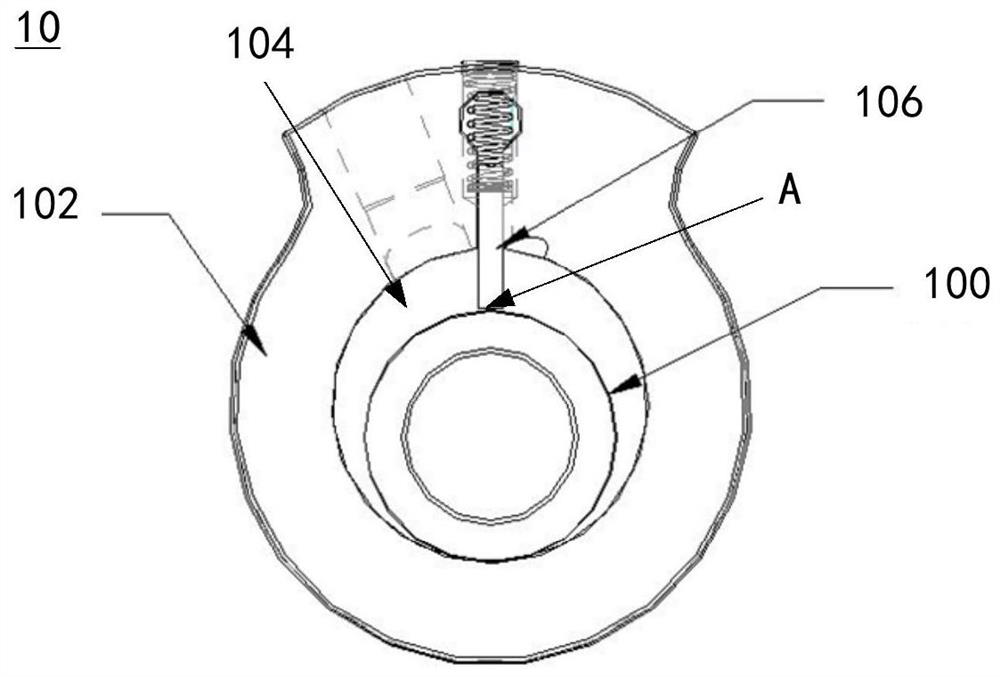

[0044] see Figure 2-Figure 3 , figure 2 It is a structural schematic diag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com