Preparing method of novel acidic dye-fixing agent for seamless underwear and prepared dye-fixing agent

An acidic color-fixing agent and seamless underwear technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of reduced stretchability, non-conformity, rough hand feeling, etc., easy to control process conditions, strong alkali and high temperature resistance , Excellent color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

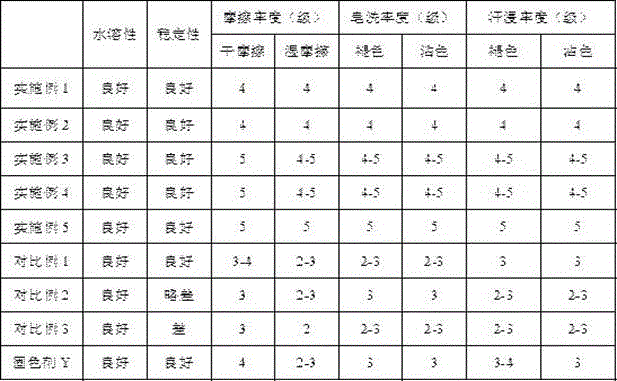

Examples

Embodiment 1

[0019] In the embodiment of the present invention, a method for preparing a novel acidic color-fixing agent for seamless underwear consists of the following steps:

[0020] 1) Mix alkanolamide with 30% ethanol whose mass is 5.2 times to prepare an alkanolamide solution; mix citric acid with deionized water to prepare a citric acid solution with a mass concentration of 42%; Vinyl ether was mixed with deionized water to prepare a solution of isomerized decanol polyoxyethylene ether with a mass concentration of 18%.

[0021] 2) Mix bisphenol S, dibutyltin oxide and alkanolamide solution, raise the temperature to 118°C, and stir at this temperature for 18min, then add hexamethyldisilazane, drop to 78°C and The temperature was stirred for 35 minutes, wherein the mass ratio of bisphenol S, dibutyltin oxide and hexamethyldisilazane was 28:1:5, and the volume ratio of hexamethyldisilazane and alkanolamide solution 1:6; then add citric acid solution, stir at 62°C for 53 minutes, where...

Embodiment 2

[0023] In the embodiment of the present invention, a method for preparing a novel acidic color-fixing agent for seamless underwear consists of the following steps:

[0024] 1) Mix alkanolamide with 30% ethanol whose mass is 5.2 times to prepare an alkanolamide solution; mix citric acid with deionized water to prepare a citric acid solution with a mass concentration of 42%; Vinyl ether was mixed with deionized water to prepare a solution of isomerized decanol polyoxyethylene ether with a mass concentration of 18%.

[0025] 2) Mix bisphenol S, dibutyltin oxide and alkanolamide solution, raise the temperature to 118°C, and stir at this temperature for 18min, then add hexamethyldisilazane, drop to 78°C and The temperature was stirred for 35 minutes, wherein the mass ratio of bisphenol S, dibutyltin oxide and hexamethyldisilazane was 36:5:13, and the volume ratio of hexamethyldisilazane and alkanolamide solution 1:8; then add citric acid solution, stir at 62°C for 53 minutes, wher...

Embodiment 3

[0027] In the embodiment of the present invention, a method for preparing a novel acidic color-fixing agent for seamless underwear consists of the following steps:

[0028] 1) Mix alkanolamide with 30% ethanol whose mass is 5.2 times to prepare an alkanolamide solution; mix citric acid with deionized water to prepare a citric acid solution with a mass concentration of 42%; Vinyl ether was mixed with deionized water to prepare a solution of isomerized decanol polyoxyethylene ether with a mass concentration of 18%.

[0029] 2) Mix bisphenol S, dibutyltin oxide and alkanolamide solution, raise the temperature to 118°C, and stir at this temperature for 18min, then add hexamethyldisilazane, drop to 78°C and The temperature was stirred for 35 minutes, wherein the mass ratio of bisphenol S, dibutyltin oxide and hexamethyldisilazane was 30:2:7, and the volume ratio of hexamethyldisilazane and alkanolamide solution 1:7; then add citric acid solution, stir at 62°C for 53 minutes, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com