Multifunctional casting polyolefine firmness-increasing film

A polyolefin and multi-functional technology, applied in the field of packaging film products, can solve the problems of poor film stiffness and high production cost, and achieve the effects of high stiffness, low use cost and good hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

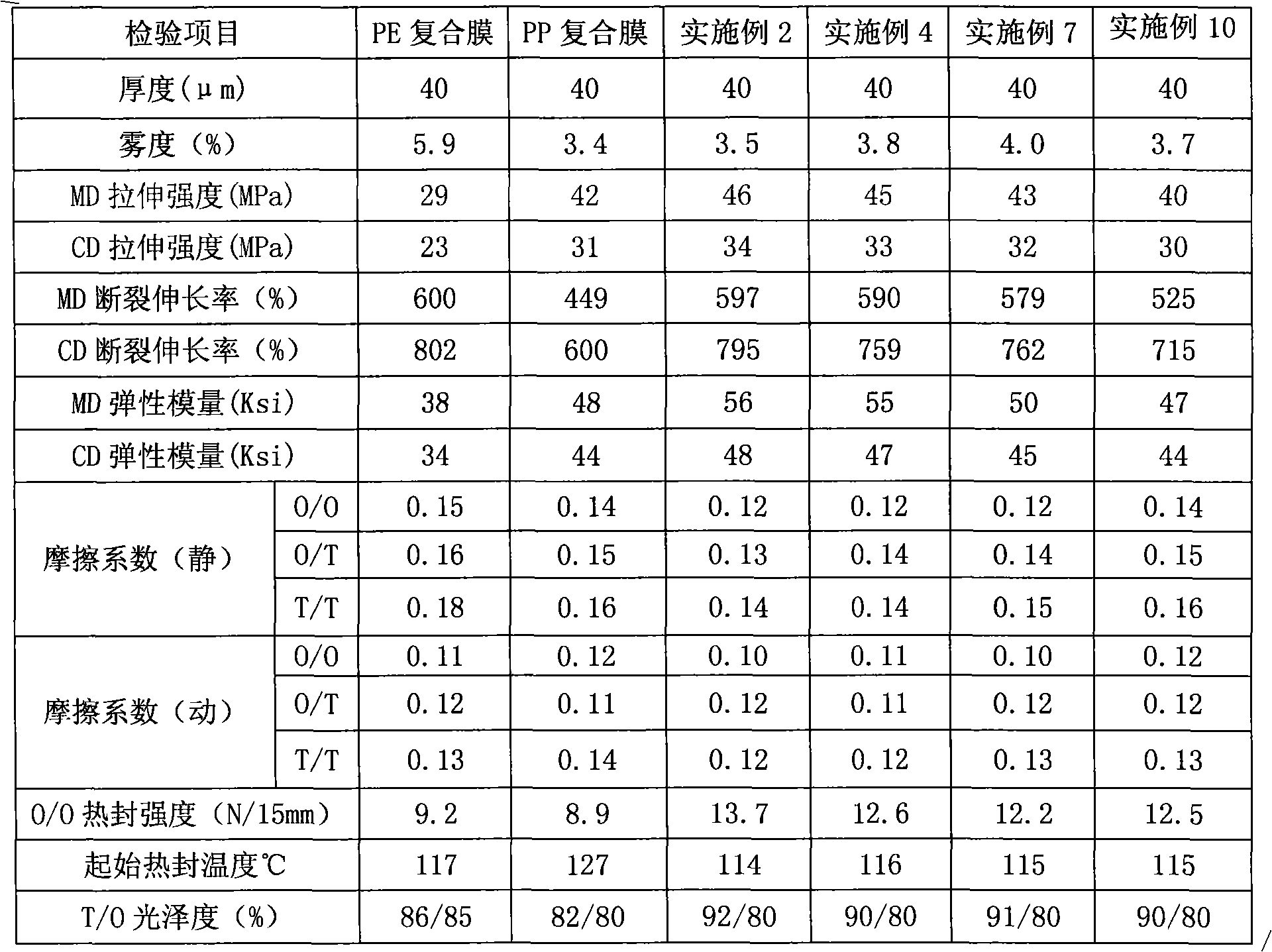

Examples

Embodiment 1

[0018] Embodiment 1: 100 parts (wherein the weight ratio of linear low density polyethylene and homopolymerized high density polyethylene is 0.67: 1) of linear low density polyethylene and high density polyethylene by weight ratio (every part of 5 kg , the same below), 43 parts of ethylene-propylene elastomer, 0.5 part of silica powder, and 0.5 part of oleic acid amide are mixed and put into the first extruder hopper and the second extruder hopper of the cast film production line respectively ; 100 parts of polypropylene resin, 0.2 part of sorbitol, 0.4 part of oleic acid amide, 4 parts of polyethylene-octene co-elastomer, and 0.3 part of monoglyceride are mixed and dropped into the third extruder hopper by weight; The molten material from the three extruders is extruded through a material collector and a T-shaped die, then cooled and shaped, the outer layer is corona treated, and the edge is trimmed to obtain a product with a heat-sealing layer, a core layer and a corona layer...

Embodiment 2

[0019] Embodiment 2: 100 parts by weight of the composition of linear low-density polyethylene and high-density polyethylene (wherein the weight ratio of linear low-density polyethylene and homopolymerized high-density polyethylene is 2: 1), ethylene-propylene elasticity 30 parts of body, 0.3 part of silicon dioxide powder, and 0.2 part of oleic acid amide are mixed and put into the first extruder hopper and the second extruder hopper of the cast film production line respectively; part, 0.8 part of sorbitol, 6 parts of polyethylene-octene co-elastomer, 0.3 part of oleic acid amide, and 0.2 part of monoglyceride are mixed and put into the third extruder hopper; The material is extruded through a material collector and a T-shaped die, then cooled and shaped, the outer layer is treated with corona, and the edge is trimmed to obtain the film product of the present invention with a heat-sealing layer, a core layer and a corona layer.

Embodiment 3

[0020] Embodiment 3: 100 parts by weight of the composition of linear low-density polyethylene and high-density polyethylene (wherein the weight ratio of linear low-density polyethylene and homopolymerized high-density polyethylene is 4: 1), ethylene-propylene elasticity 15 parts of body, 0.1 part of silica powder, and 0.1 part of oleic acid amide are mixed and put into the first extruder hopper and the second extruder hopper of the cast film production line respectively; part, 1.1 parts of sorbitol, 7 parts of polyethylene-octene co-elastomer, 0.2 part of oleic acid amide, and 0.1 part of monoglyceride are mixed and put into the third extruder hopper; The material is extruded through a material collector and a T-shaped die, then cooled and shaped, the outer layer is treated with corona, and the edge is trimmed to obtain the film product of the present invention with a heat-sealing layer, a core layer and a corona layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com