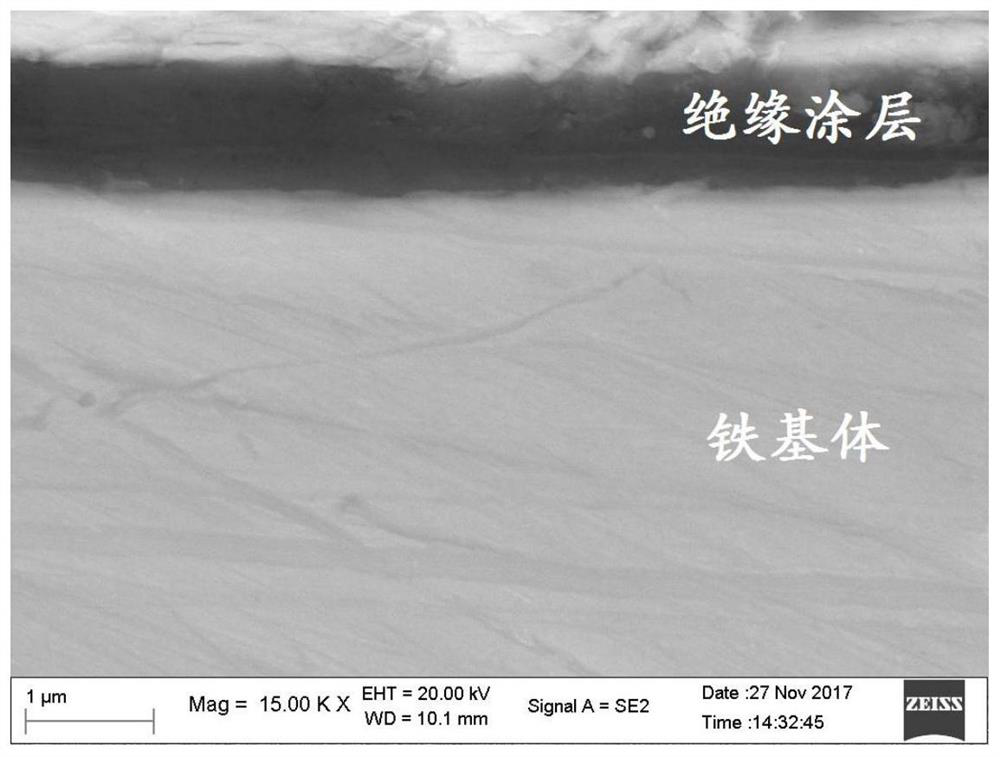

A kind of insulating coating on the surface of ultra-thin silicon steel and its preparation method

A technology of insulating coating and silicon steel, applied in the direction of coating, fireproof coating, etc., can solve the problems of poor adhesion on the surface of ultra-thin silicon steel, thick insulating coating on the surface of oriented silicon steel, etc., achieve excellent adhesion performance, reduce iron loss, improve Dispersion and Uniformity Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

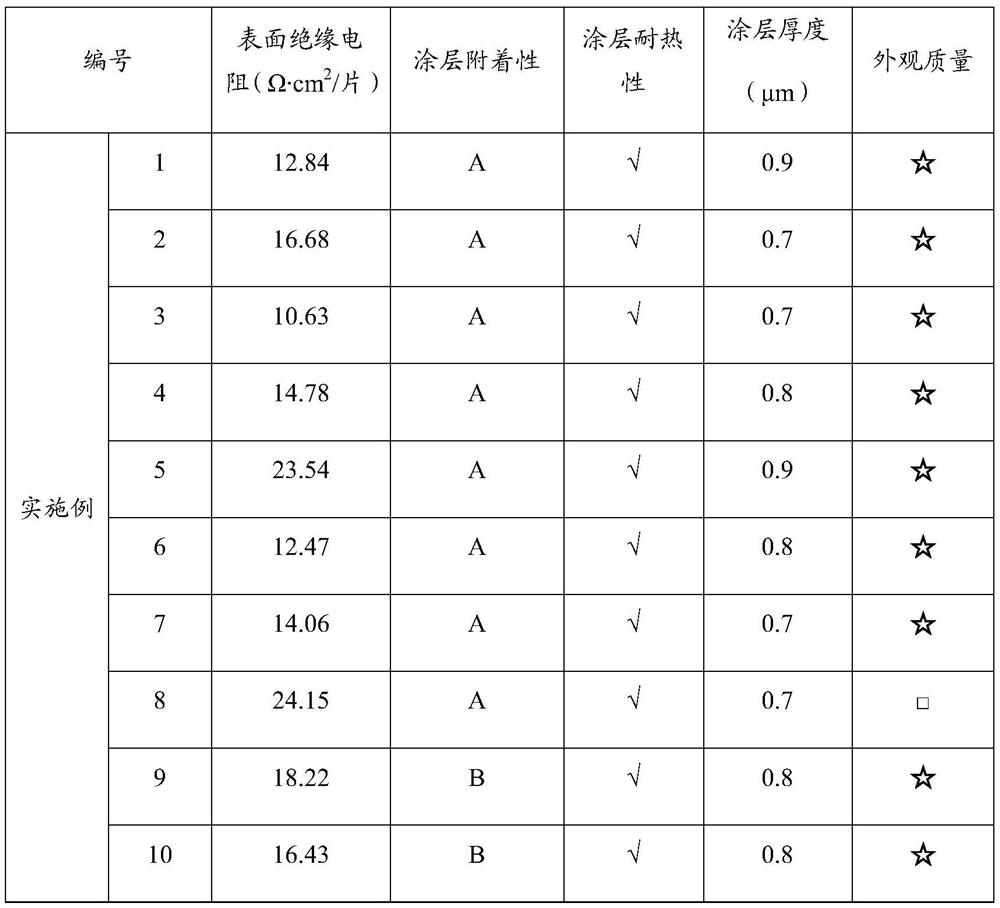

Examples

Embodiment 1

[0051] This embodiment provides an insulating coating, and its raw material composition is: 75g of magnesium dihydrogen phosphate, 1.2g of titanium nitride, 3g of boric acid, 10g of silica sol, 0.12g of magnesium stearate, and 0.06g of modified polysiloxane , silicone resin 3g, deionized water 7.62g. Wherein, magnesium dihydrogen phosphate is obtained by reacting phosphoric acid with an initial concentration of 23 wt% and magnesium oxide of 8 wt% in deionized water.

[0052] The insulating coating of this embodiment is obtained by the following method: stir and mix deionized water and silica sol evenly, let it stand for 30 minutes, and then add magnesium dihydrogen phosphate, boric acid, titanium nitride, silicone resin, and stearic acid in sequence Magnesium, modified polysiloxane, each component is fully stirred by an automatic mixer during the addition process to ensure that the coating liquid is mixed evenly and the suspended particles are dispersed. After each component i...

Embodiment 2

[0057] This embodiment provides an insulating coating, and its raw material composition is: 70g of magnesium dihydrogen phosphate, 0.8g of titanium nitride, 2g of boric acid, 12g of silica sol, 0.12g of AFCONA-4530, 0.06g of dimethylsiloxane, Film-forming resin 3g, deionized water 12.02g. Wherein, magnesium dihydrogen phosphate is obtained by reacting phosphoric acid with an initial concentration of 20 wt% and magnesium oxide of 5 wt% in deionized water.

[0058] The insulating coating of this embodiment is obtained by the following method, stir and mix deionized water and silica sol evenly, let it stand for 30 minutes, and then add magnesium dihydrogen phosphate, boric acid, titanium nitride, film-forming resin, and dispersant in sequence , defoaming agent, each component is added with an automatic mixer to fully stir to ensure that the coating liquid is mixed evenly and the suspended particles are dispersed. After each component is added, it is left to stand for 30 minutes, ...

Embodiment 3

[0063] This embodiment provides an insulating coating, the raw materials of which are composed of 78g of magnesium dihydrogen phosphate, 0.5g of titanium nitride, 2.2g of boric acid, 5g of silica sol, 0.09g of oxidized polyethylene wax, 0.06g of AFCONA-2592, and Resin 2.5g, deionized water 11.65g. Wherein, magnesium dihydrogen phosphate is obtained by reacting phosphoric acid with an initial concentration of 30 wt% and magnesium oxide of 15 wt% in deionized water.

[0064] The insulating coating of this embodiment is obtained by the following method, stir and mix deionized water and silica sol evenly, let it stand for 30 minutes, and then add magnesium dihydrogen phosphate, boric acid, titanium nitride, film-forming resin, and dispersant in sequence , defoaming agent, each component is added with an automatic mixer to fully stir to ensure that the coating liquid is mixed evenly and the suspended particles are dispersed. After each component is added, it is left to stand for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com