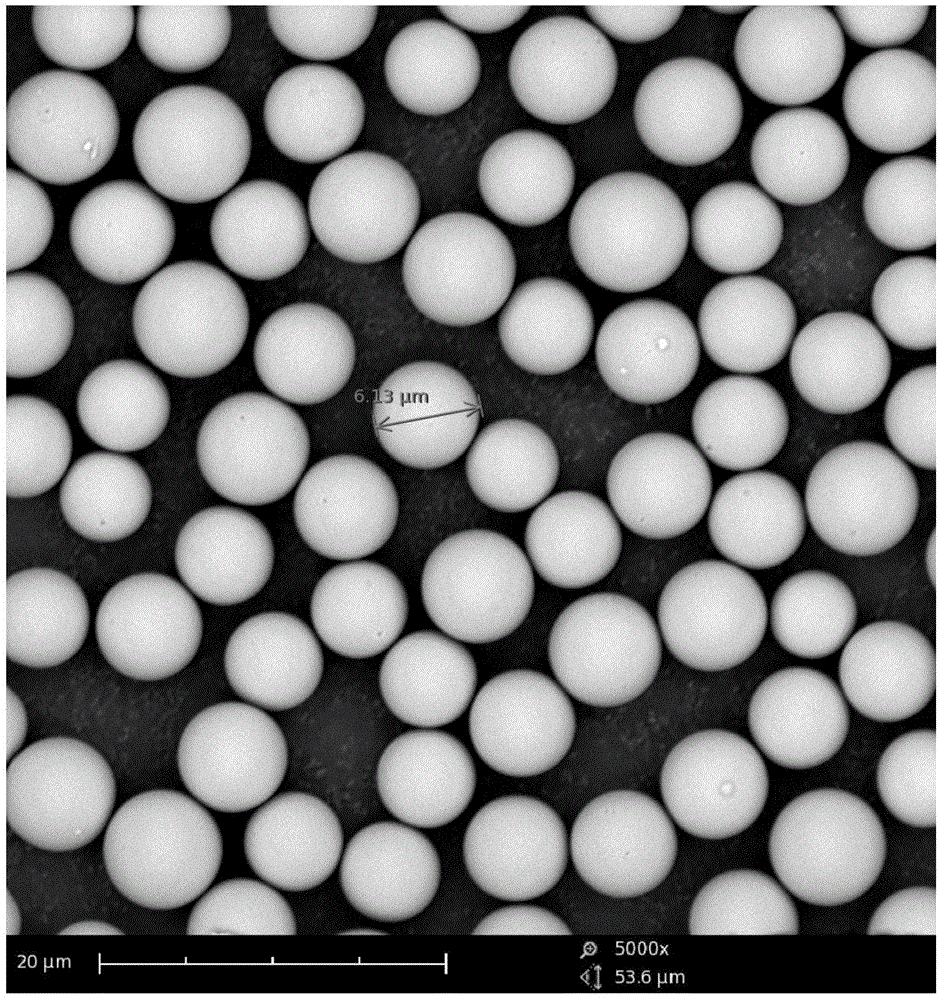

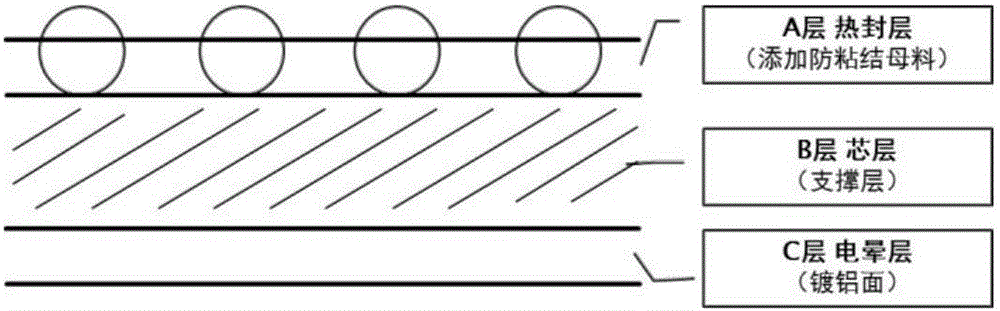

Low-friction coefficient anti-bonding master batch special for metallized base film and preparation method thereof

A low friction coefficient, metallized technology, applied in the field of functional polymer materials, can solve the problems of high hardness, easy to scratch the film surface and wear equipment, etc., and achieve the effect of low surface energy, good processing performance and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0034] The materials were weighed according to the formula shown in Table 1 to prepare a low friction coefficient anti-adhesion masterbatch for metallized base film.

[0035] Components and contents thereof in Table 1 Embodiment 1-6

[0036]

[0037] The binary copolymerized polypropylene in the embodiment has a melt index of 7-9g / 10min; it can also be replaced with a ternary copolymerized polypropylene with a melt index of 7-9g / 10min.

[0038] Wherein the synthesis method of PMSQ-PPSQ is: PhSi(OEt) 3 and MeSi(OEt) 3 Soluble in benzene, and under the catalysis of a small amount of HCL, use ultra-pure water for hydrolysis and condensation to obtain a high-purity ladder polymer with hydroxyl terminated and side chains containing methyl and phenyl groups; then add polysilicon under the condition of nitrogen gas oxane mass half of R 3 SiCl (R is Me, Et, Ph), kept at about 90°C for 2h to terminate the reaction. end up with R 3 SiO (R is Me, Et, Ph) terminated ladder polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com