Cover film with high-temperature boiling and sterilization resistance

A technology of high-temperature cooking and covering film, which is applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of poor quality stability of the covering film, and achieve improved retort and sterilization resistance and good composite fastness , enhance the effect of surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

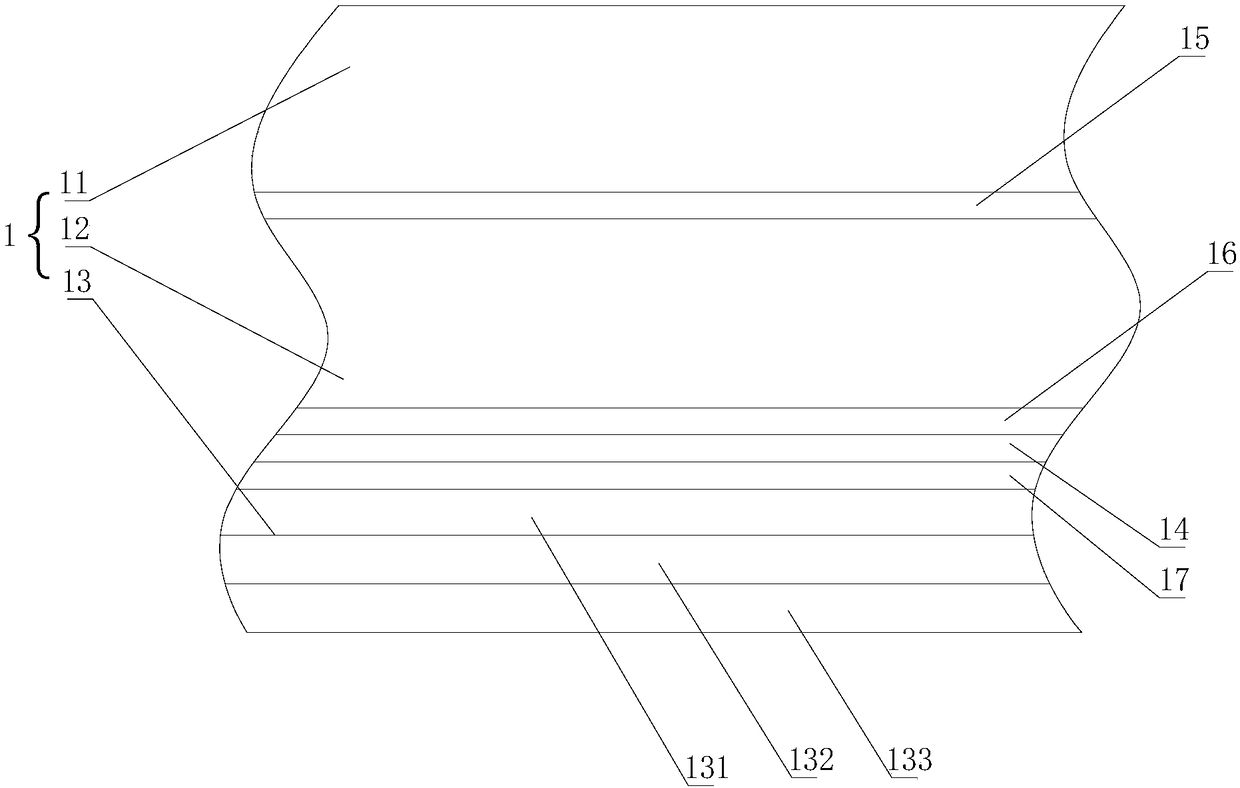

[0024] Such as figure 1 As shown, a cover film that can be retorted and sterilized at high temperature includes a main body 1, and the main body 1 includes a PET layer 11, an aluminum layer 12 and a PE layer 13 in sequence from the outside to the inside, and the PE layer 13 includes a composite layer 131, a middle layer 132 and a heat-sealing layer 133 , the aluminum layer 12 is disposed on the composite layer 131 . A thin film layer 14 is provided between the aluminum layer 12 and the composite layer 131. Through the setting of the thin film layer 14, it is ensured that the aluminum layer 12 is reliably composited on the PE layer 13, and the composite cover film is not deformed as a whole. Effectively improve the overall retort and sterilization performance of the cover film;

[0025] The composite layer 131 includes the following components: 100 parts by mass of low-density polyethylene, 5-15 parts by mass of linear low-density polyethylene, and 1-3 parts by mass of PPA; du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corona value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com