Rubber-type light curing 3D printing material and preparation method thereof

A 3D printing and light-curing technology, which is applied in the field of rubber-type light-curing 3D printing materials and its preparation, can solve the problems of high hardness, limited application range and development, and low flexibility, and achieve low hardness, high elasticity, and high molding precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

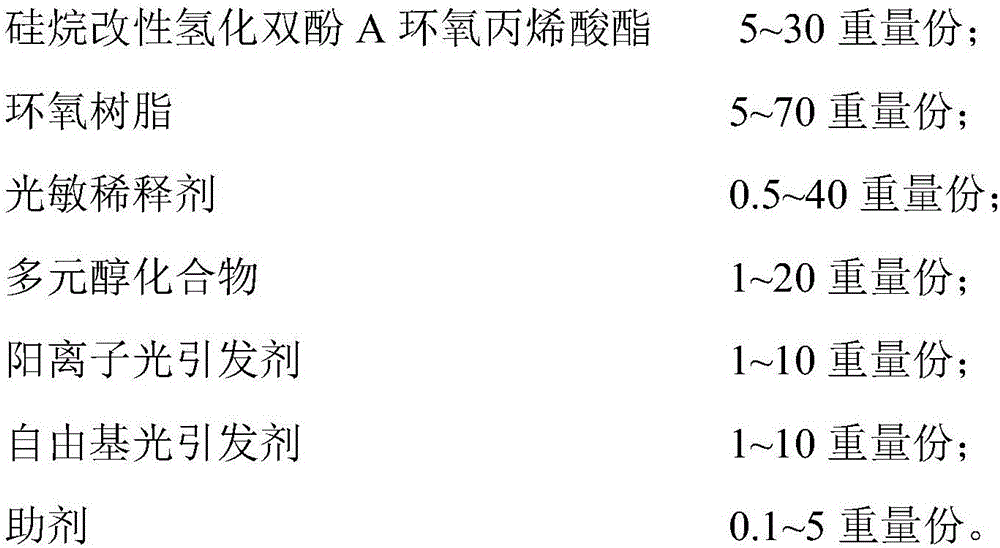

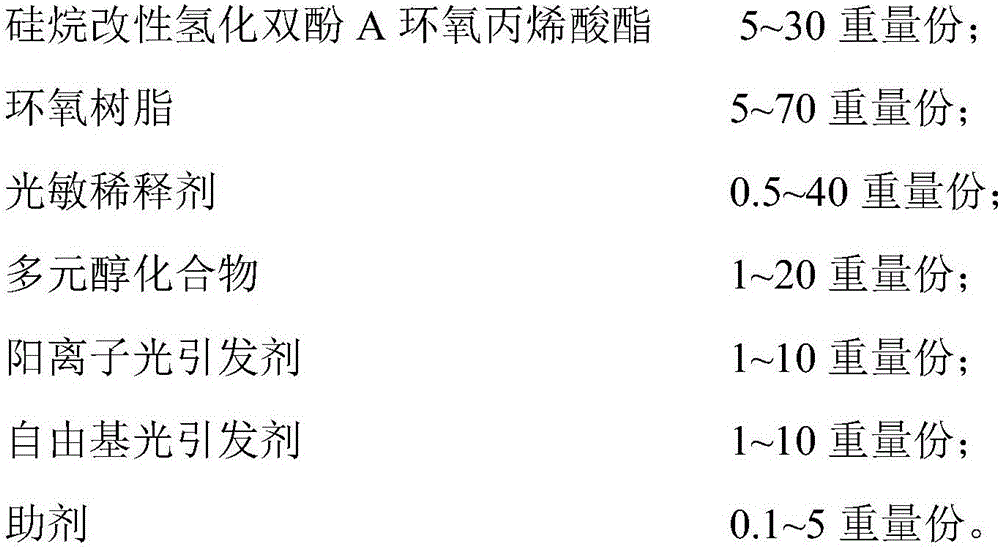

Method used

Image

Examples

preparation example Construction

[0031] Correspondingly, the present invention also provides a method for preparing a rubber-type photocurable 3D printing material, comprising the following steps: mixing the silane-modified hydrogenated bisphenol A epoxy acrylate, epoxy resin, and photosensitive diluent described in the above technical solution , a polyol compound, a cationic photoinitiator, a free radical photoinitiator and an auxiliary agent are mixed, and stirred at 20-60° C. for 30-120 minutes to obtain a rubber-type photocurable 3D printing material. Among them, the stirring temperature is preferably 30-50°C, more preferably 30-40°C; the stirring time is preferably 40-100 minutes, more preferably 50-90 minutes.

[0032] In the present invention, the raw materials are mixed according to the mass percentage, and fully stirred evenly, that is, the rubber-type 3D printing photosensitive resin with high elasticity and high flexibility is prepared. The light-cured product prepared by the present invention has ...

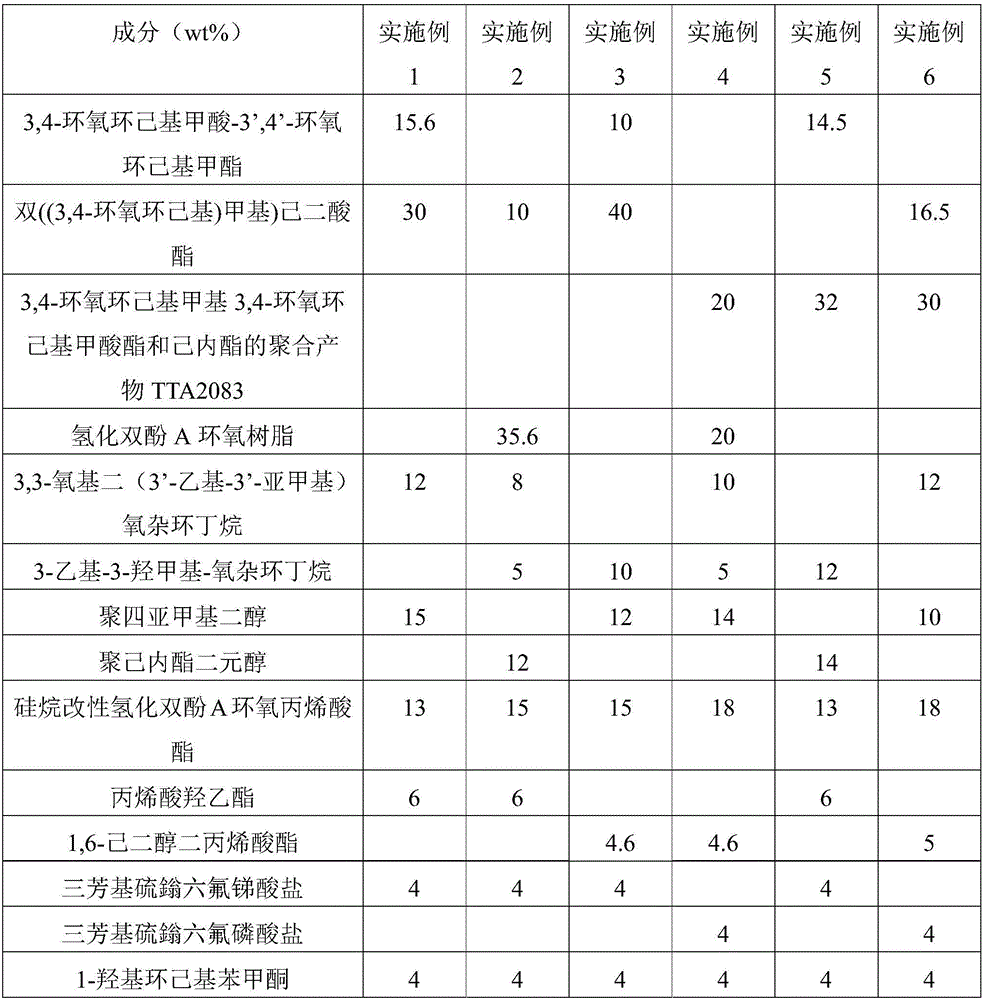

Embodiment 1-6

[0037] Add 100g of hydrogenated bisphenol A epoxy acrylate and 2g of dibutyltin dilaurate catalyst into the three-necked flask and stir, then slowly add 4g of KH-560 dropwise into the flask, heat to 75-85°C, then add 0.1-10g dropwise Distilled water, react at 90°C for 5-6 hours to obtain silane-modified hydrogenated bisphenol A epoxy acrylate;

[0038] Using the raw materials and weight percentages shown in Table 1, mix each raw material, and mechanically stir at 20-60°C for 30-120 minutes until the components are evenly mixed to obtain a rubber-type photocurable 3D printing material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com