Modified auxiliary capable of improving printing compound performance of polypropylene film, preparation method and application

A technology of polypropylene film and polypropylene, which is applied in the field of polypropylene processing aids, can solve the problem of peeling of the sheet structure without mentioning vermiculite, poor printing and composite performance of polypropylene film, and composite strength (small peel strength, etc.) problems, to achieve the effects of improved comprehensive performance, improved printing composite performance, and improved peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

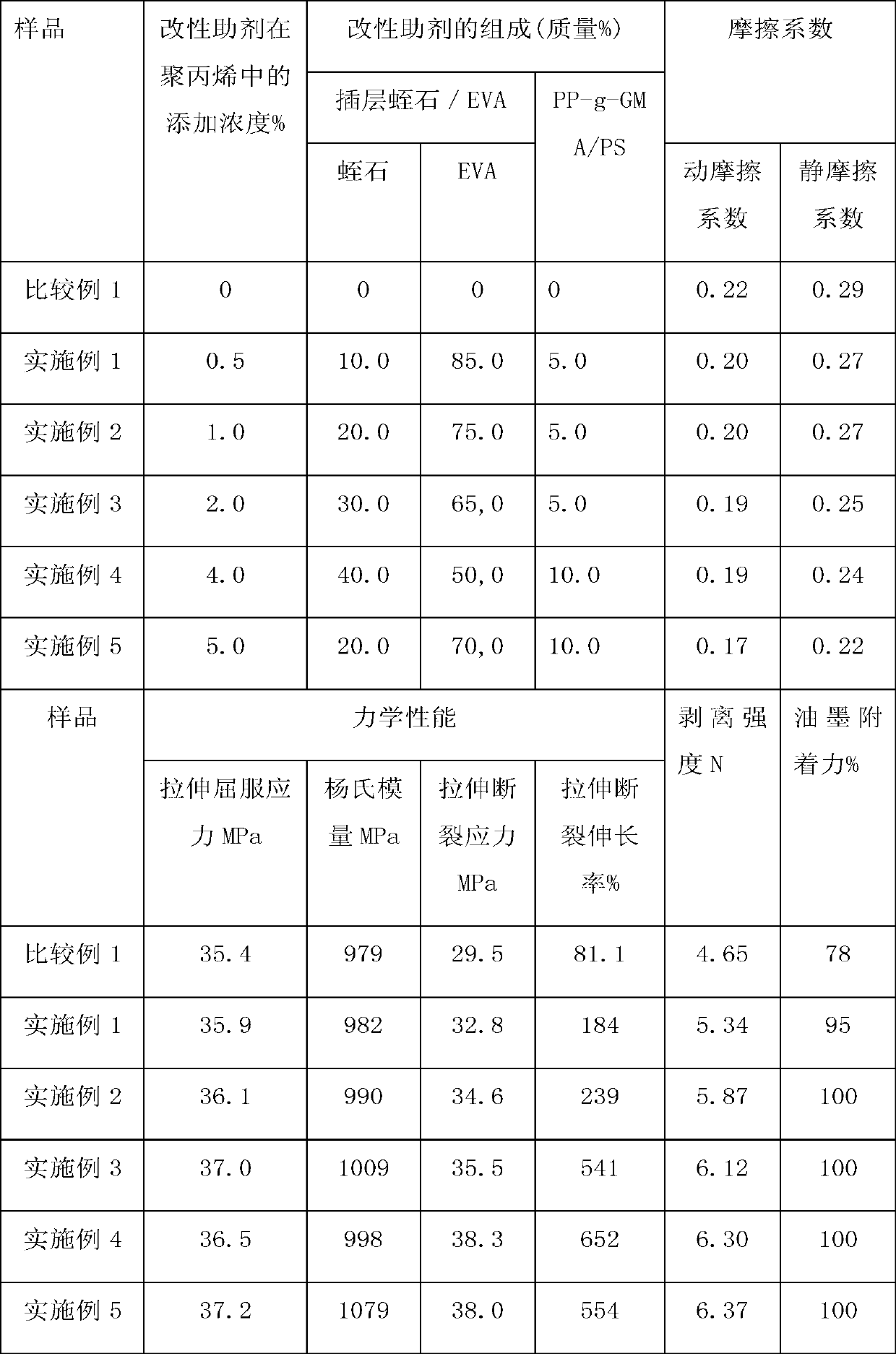

Examples

Embodiment 1

[0022] In Example 1, n-hexane was used as solvent when preparing intercalated vermiculite / EVA, and other operating conditions were as above.

Embodiment 2

[0023] Example 2 uses n-hexane and acetone as a mixed solvent when preparing intercalated vermiculite / EVA, wherein acetone accounts for 10% of the total solvent amount; other conditions are the same as in Example 1.

Embodiment 3

[0024] Example 3 used n-hexane and butanone as a mixed solvent when preparing intercalated vermiculite / EVA, wherein butanone accounted for 10% of the total solvent amount; other conditions were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com