A kind of pvc reinforcement board and preparation method thereof

A technology of reinforced board and PVC resin powder, which is applied in the field of PVC reinforced board and its preparation, and can solve the problems that the notched impact strength, tensile elongation at break and tensile properties cannot be improved at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

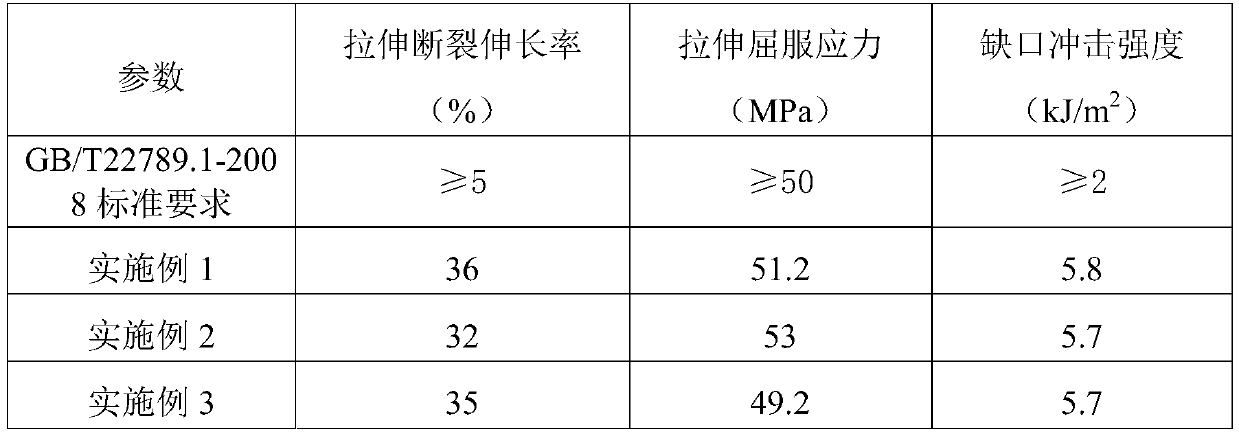

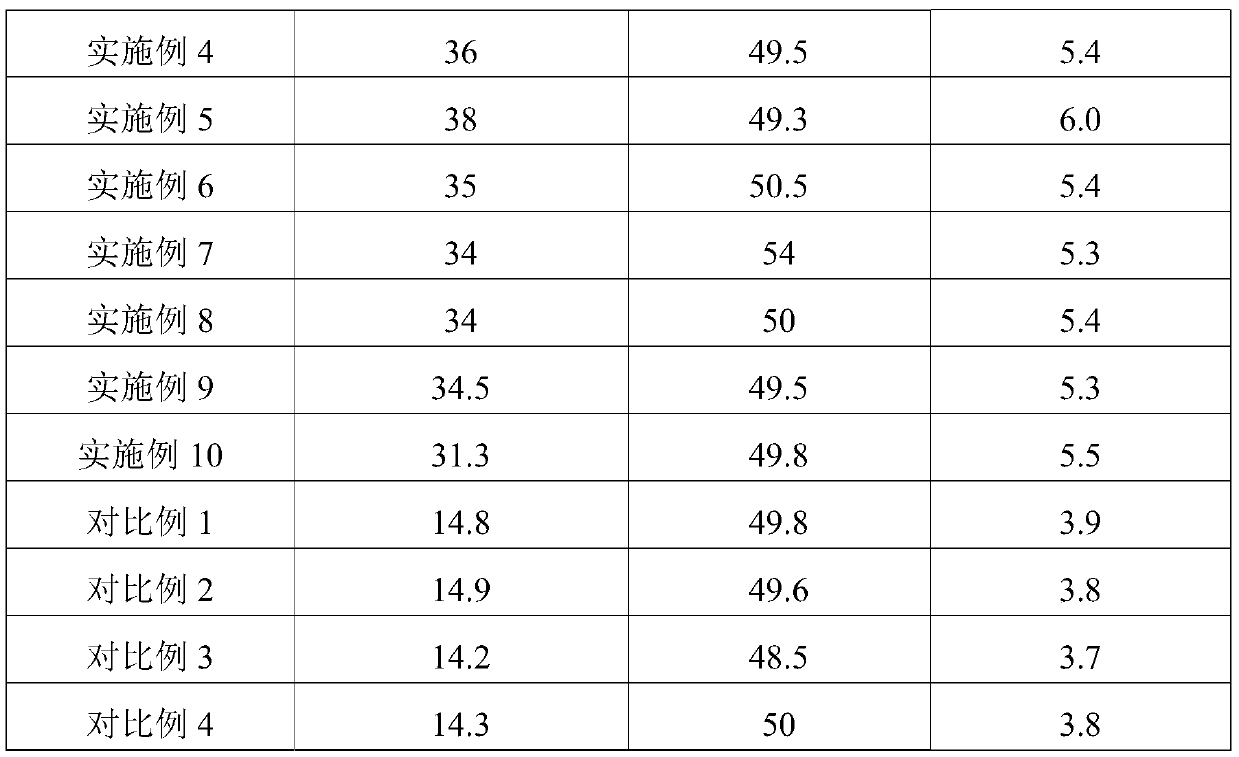

Examples

Embodiment 1

[0022] The present embodiment 1 is prepared according to the following components: 100kg PVC resin powder, 1kg tribasic lead sulfate, 4kg composite lead stabilizer, 0.7kg barium stearate, 0.8kg calcium stearate, 3kg chlorinated polyethylene, 2kgACR high resistance Punch type modifier, 0.8kg rare earth coupling agent, 10kg active calcium carbonate; and above-mentioned preparation method prepares PVC reinforced plate by above-mentioned preparation method.

Embodiment 2

[0024] The present embodiment 2 is prepared according to the following components: 100kg PVC resin powder, 3kg tribasic lead sulfate, 2kg composite lead stabilizer, 0.3kg barium stearate, 0.6kg calcium stearate, 1.5kg chlorinated polyethylene, 2kgACR high Anti-impact modifier, 0.5kg rare earth coupling agent, 8kg active calcium carbonate; and prepare PVC reinforced board according to the above preparation method.

Embodiment 3

[0026] Present embodiment 3 is prepared according to the following components: 100kg PVC resin powder, 2kg tribasic lead sulfate, 3kg composite lead stabilizer, 1.2kg barium stearate, 1.2kg calcium stearate, 4kg chlorinated polyethylene, 1.3kg ACR high Anti-impact modifier, 1.5kg rare earth coupling agent, 8kg active calcium carbonate; and prepare PVC reinforced board according to the above preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com