Scratch-resistant impact-resistant polypropylene material and preparation method thereof

A polypropylene material and scratch-resistant technology, which is applied in the field of scratch-resistant and impact-resistant polypropylene materials and their preparation, can solve the problems of increasing material cost and affecting material properties, so as to improve scratch resistance, improve mechanical properties, The effect of improved scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

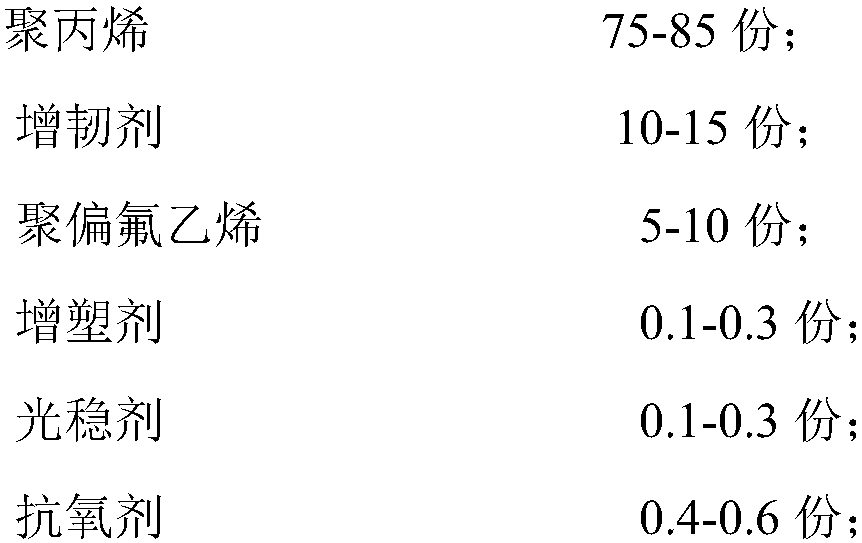

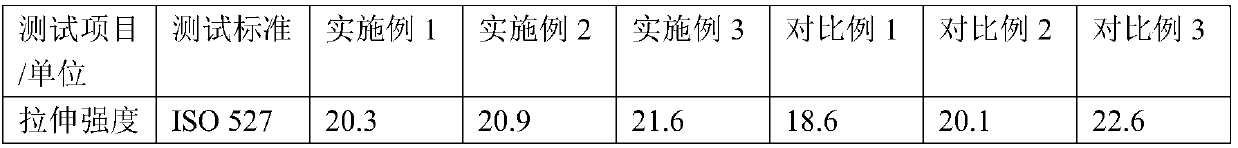

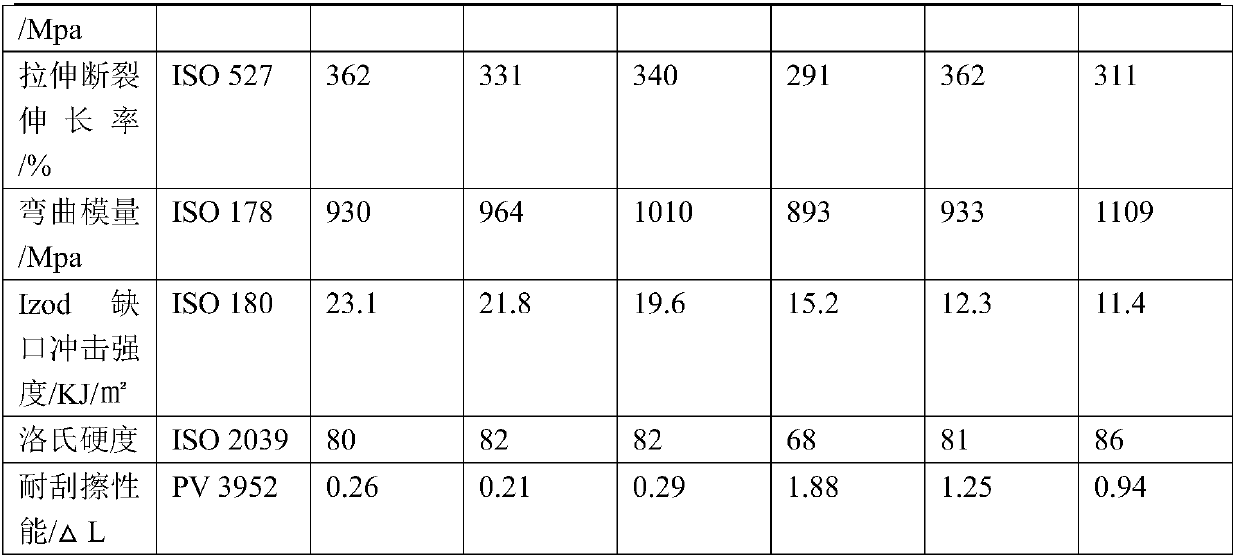

[0024] Add 75 parts of polypropylene, 15 parts of toughening agent, 10 parts of polyvinylidene fluoride, 0.1 part of plasticizer, 0.1 part of light stabilizer, and 0.4 part of antioxidant into the high-mixer and mix for 10 minutes; then mix the uniform material Add it into a twin-screw extruder, knead, extrude, cool and cut into pellets to obtain scratch-resistant and impact-resistant polypropylene material pellets; the extrusion temperature of each extrusion section in the twin-screw extruder is 150°C, 160°C, 175°C, 185°C, 190°C, 190°C, 190°C, 190°C, 190°C, 200°C.

Embodiment 2

[0026] Add 80 parts of polypropylene, 10 parts of toughening agent, 10 parts of polyvinylidene fluoride, 0.3 parts of plasticizer, 0.3 parts of light stabilizer, and 0.6 parts of antioxidant into the high-mixer and mix for 10 minutes; then mix the uniform material Add it into a twin-screw extruder, knead, extrude, cool and cut into pellets to obtain scratch-resistant and impact-resistant polypropylene material pellets; the extrusion temperature of each extrusion section in the twin-screw extruder is 155°C, 165°C, 170°C, 190°C, 195°C, 195°C, 195°C, 195°C, 195°C, 205°C.

Embodiment 3

[0028] Add 85 parts of polypropylene, 10 parts of toughening agent, 5 parts of polyvinylidene fluoride, 0.2 parts of plasticizer, 0.2 parts of light stabilizer, and 0.5 parts of antioxidant into the high-mixer and mix for 10 minutes; then mix the uniform material Add it into a twin-screw extruder, knead, extrude, cool and cut into pellets to obtain scratch-resistant and impact-resistant polypropylene material pellets; the extrusion temperature of each extrusion section in the twin-screw extruder is 160°C, 175°C, 185°C, 195°C, 200°C, 200°C, 200°C, 200°C, 200°C, 210°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com