Process for production of hard coat film

A manufacturing method, a technology for hard coating films, applied in the directions of chemical instruments and methods, devices for applying liquid to surfaces, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

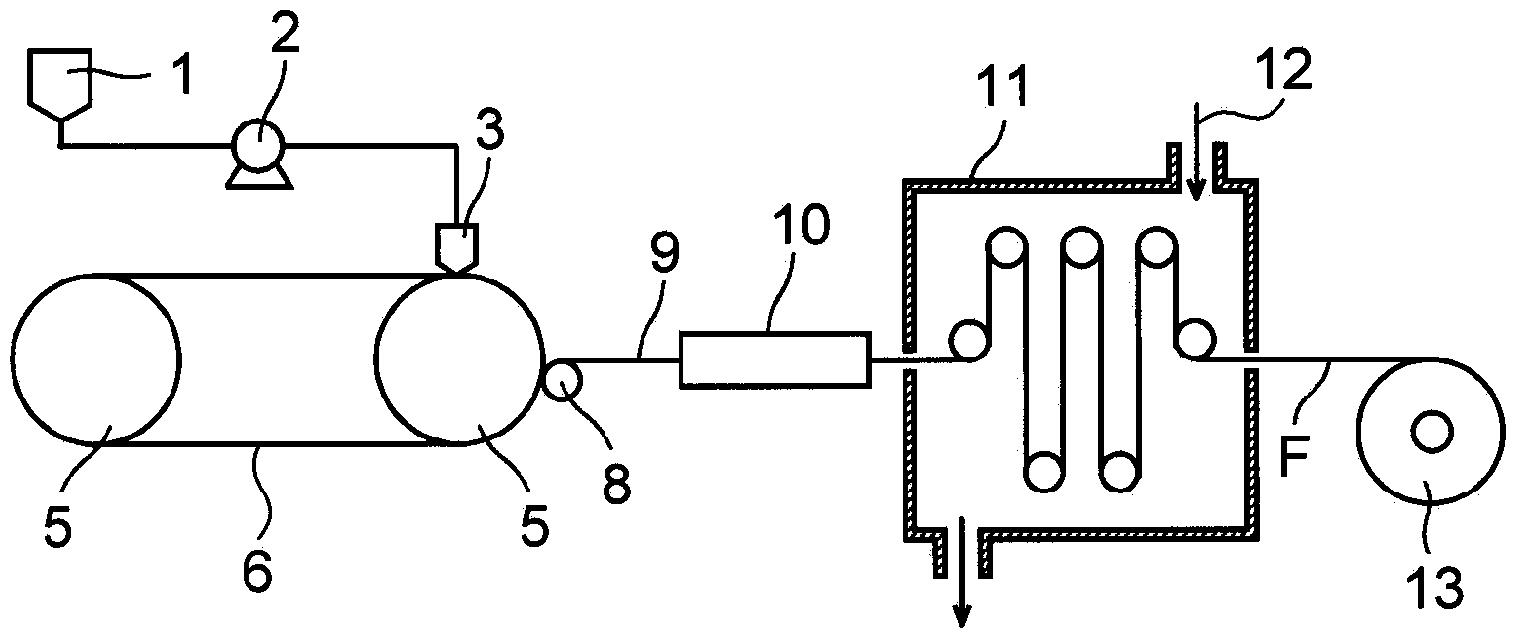

[0279] (Production of cellulose ester film)

[0280] · Preparation of silica dispersion

[0281] AEROSIL R812 (manufactured by Japan Aerosil Co., Ltd.) 10 parts by mass

[0282] (The average diameter of primary particles is 7nm)

[0283] 90 parts by mass of ethanol

[0284] The above materials were stirred and mixed with a dissolver for 30 minutes, and then dispersed with a Manton Gaulin. While stirring, 88 parts by mass of methylene chloride was added to the silica dispersion, and stirred and mixed in a dissolver for 30 minutes to prepare a silica dispersion dilution. Filtration was performed with a fine particle dispersion diluent filter (Advantec Toyo Co., Ltd.: polypropylene wound filter TCW-PPS-1N).

[0285]

[0286] (cellulose ester resin)

[0287] Cellulose triacetate A (cellulose triacetate synthesized from cotton linters, acetyl substitution degree 2.88, Mn=140000) 90 parts by mass

[0288] (additive)

[0289] X-1 5 parts by mass

[0290] X-12 4 parts by mas...

Embodiment 2

[0350] Except having made content of the plasticizer A in the cellulose ester film of a hard coat into 1 weight%, it was the same as Example 1.

Embodiment 3

[0352] Except having made content of the plasticizer A in the cellulose ester film of a hard coat into 20 weight%, it was the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com