Antifouling coating material and preparation method and application thereof

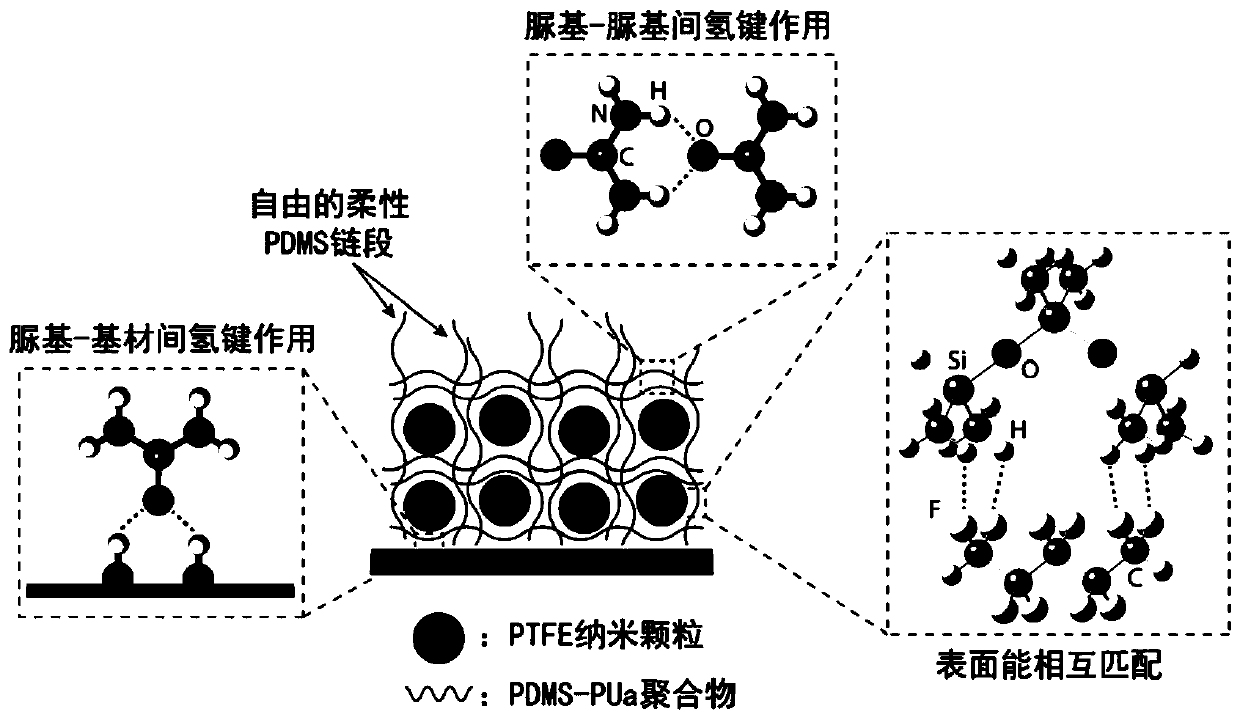

A technology of antifouling coatings and raw materials, applied in antifouling/underwater coatings, coatings, polyurea/polyurethane coatings, etc. Pollution performance cannot be balanced, avoid chemical crosslinking, high flexibility and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

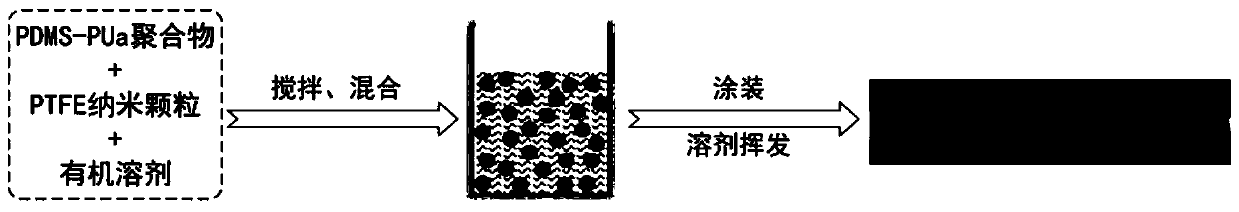

[0044] Preparation of low surface energy antifouling materials based on multiple physical crosslinking:

[0045] (1) Add 30.00 g of bisamino-terminated PDMS (molecular weight ~ 3000 g / mol) and 45 ml of tetrahydrofuran into a three-necked flask, seal it, place it in a water bath at 25 °C, pass nitrogen gas for 10 min, and stir magnetically at 300 rpm for 30 min.

[0046] (2) Dissolve 1.68 g of hexamethylene diisocyanate in 5 ml of tetrahydrofuran, and add it dropwise to the three-necked flask in step (1), pass nitrogen gas in a water bath at 25°C for 10 min, and stir magnetically at 300 rpm for 24 h.

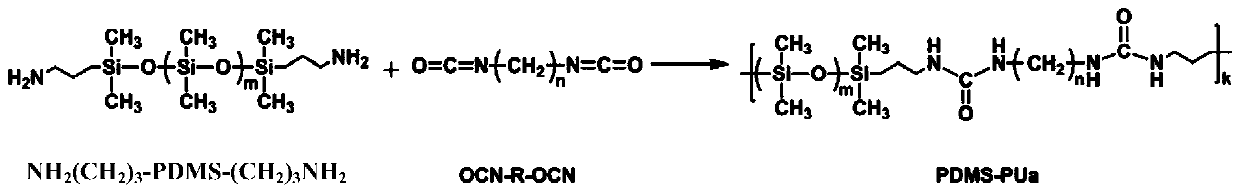

[0047] The reaction equation for the copolymerization of double-blocked PDMS and hexamethylene diisocyanate is as follows: figure 1 Shown, wherein R is a hexamethylene group. The molar concentration of diamino-terminated PDMS in the solution is 0.2mol / L, the molar concentration of hexamethylene diisocyanate is 0.2mol / L, and the molar ratio of amino groups to isocyanate groups is...

Embodiment 2

[0055] Preparation of low surface energy antifouling materials based on multiple physical crosslinking:

[0056] (1) Add 30.00 g of bisamino-terminated PDMS (molecular weight ~ 3000 g / mol) and 45 ml of tetrahydrofuran into a three-necked flask, seal it, place it in a water bath at 25 °C, pass nitrogen gas for 10 min, and stir magnetically at 300 rpm for 30 min.

[0057] (2) 1.68g of hexamethylene diisocyanate (HDI) was dissolved in 5ml of tetrahydrofuran, and added dropwise to the three-necked flask of step (1), nitrogen gas flowed in a water bath at 25°C for 10min, and magnetic stirring at 300rpm for 24h.

[0058] The reaction equation for the copolymerization of double-blocked PDMS and hexamethylene diisocyanate is as follows: figure 1 Shown, wherein R is a hexamethylene group. The molar concentration of diamino-terminated PDMS in the solution is 0.2mol / L, the molar concentration of hexamethylene diisocyanate is 0.2mol / L, and the molar ratio of amino groups to isocyanate gr...

Embodiment 3

[0066] Preparation of low surface energy antifouling materials based on multiple physical crosslinking:

[0067](1) Add 30.00 g of bisamino-terminated PDMS (molecular weight ~ 3000 g / mol) and 45 ml of tetrahydrofuran into a three-necked flask, seal it, place it in a water bath at 25 °C, pass nitrogen gas for 10 min, and stir magnetically at 300 rpm for 30 min.

[0068] (2) 1.68g of hexamethylene diisocyanate (HDI) was dissolved in 5ml of tetrahydrofuran, and added dropwise to the three-necked flask of step (1), nitrogen gas flowed in a water bath at 25°C for 10min, and magnetic stirring at 300rpm for 24h.

[0069] The reaction equation for the copolymerization of double-blocked PDMS and hexamethylene diisocyanate is as follows: figure 1 Shown, wherein R is a hexamethylene group. The molar concentration of diamino-terminated PDMS in the solution is 0.2mol / L, the molar concentration of hexamethylene diisocyanate is 0.2mol / L, and the molar ratio of amino groups to isocyanate gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface free energy | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com