Offset printing plate, offset printing plate material, support for offset printing plate and offset printing method

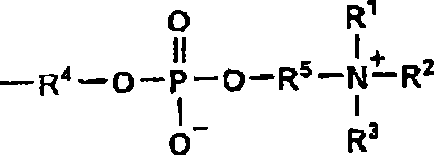

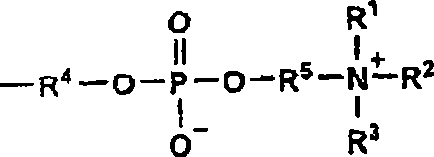

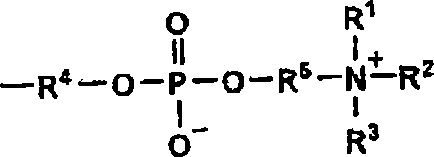

A lithographic printing plate and support technology, which is applied in the field of lithographic printing plates and lithographic printing plate materials, can solve the problems of low sensitivity, inability to obtain image reproducibility, operability restrictions, etc., and achieve good anti-pollution and stable thermal storage sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0227] [Support 1]

[0228] An aluminum plate (material 1050, tempered H16) with a thickness of 0.24mm is immersed in a 1% by mass sodium hydroxide aqueous solution at 50°C, and dissolved so that the amount of dissolution is 2g / m 2 , After washing with water, it was immersed in a 5% by mass nitric acid aqueous solution at 25° C. for 30 seconds to perform a neutralization treatment, and then washed with water.

[0229] Subsequently, through the electrolyte containing hydrochloric acid 11g / L, acetic acid 10g / L, aluminum 8g / L, with sine wave alternating current, the current peak density is 80A / dm 2 Under the conditions, the aluminum plate is subjected to electrolytic surface roughening treatment. At this time, the distance between the electrode and the sample surface was 10 mm. The electrolytic surface roughening treatment is carried out in 8 times, and the electricity (at the anode) of one treatment is 40C / dm 2 , the total treatment power (at the anode) is 320C / dm 2 . In ad...

Embodiment 2

[0280] [Production of Support 4]

[0281] The support 1 was immersed in a 70° C. treatment solution containing 0.5% by mass of the phosphobetaine compound [1] for 30 seconds. Then, after washing with pure water, it was dried at 80° C. for 2 minutes to obtain a support 4 .

[0282] The image forming layer was coated on the support 4 in the same manner as the printing plate material 5 (sample No. 5), to obtain a printing plate material 10 .

[0283] The same evaluation as in Example 1 was carried out. The number of on-press developed sheets was 20 sheets, and the printing durability was 20,000 sheets or more regardless of the presence or absence of heat preservation treatment. Chemical resistance: ◯, good result.

Embodiment 3

[0285] [Production of Support 5]

[0286] An aluminum plate (material 1050, tempered H16) with a thickness of 0.24mm is immersed in a 1% by mass sodium hydroxide aqueous solution at 50°C, and dissolved so that the dissolved amount is 2g / m 2 , After washing with water, immerse in 0.1% by mass hydrochloric acid aqueous solution at 25° C. for 30 seconds, and wash with water after neutralization treatment.

[0287] Subsequently, using an electrolyte solution containing 10g / L hydrochloric acid, 10g / L acetic acid, and 5g / L aluminum, using sine wave alternating current, the current peak density is 50A / dm 2 Under the conditions, the aluminum plate is subjected to electrolytic surface roughening treatment. At this time, the distance between the electrode and the sample surface was 10 mm. The electrolytic surface roughening treatment is carried out in 8 times, and the electricity (at the anode) of one treatment is 40C / dm 2 , the total treatment power (at the anode) is 320C / dm 2 . I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com