Image recording material and image formation process thereof

An image recording and image technology, which is applied in the temperature recording method, the photoplate making process of the pattern surface, and the photosensitive material used in the photomechanical equipment, etc. Improving visibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0265] Example 1 (Image recording material)

[0266] Preparation of coating solution

[0267] The coating liquid 1 having the composition shown below was prepared. Except for the surfactant, the materials on the table were mixed and stirred using a homogenizer, and then the surfactant was added and stirred, and then filtered to obtain coating liquid 1.

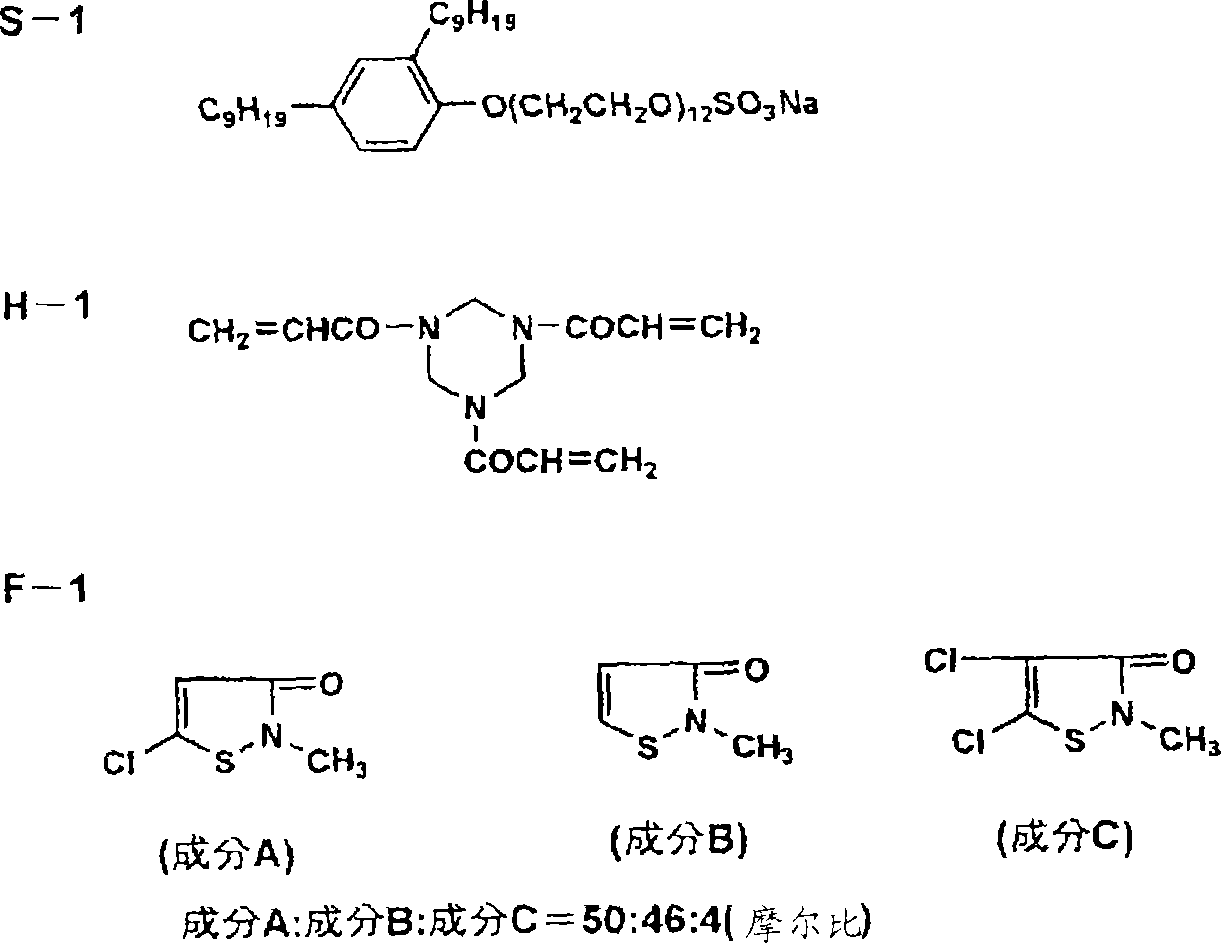

[0268] Composition of coating liquid 1 (solid content 30% by mass) (Numerical values without units listed in the table indicate parts by mass)

[0269] Table 1

[0270] Material

[0271] Then, the thermal image forming layer coating liquids (1) to (8) having the following compositions were prepared. After thoroughly mixing and stirring each material in the table, filter to obtain each coating liquid.

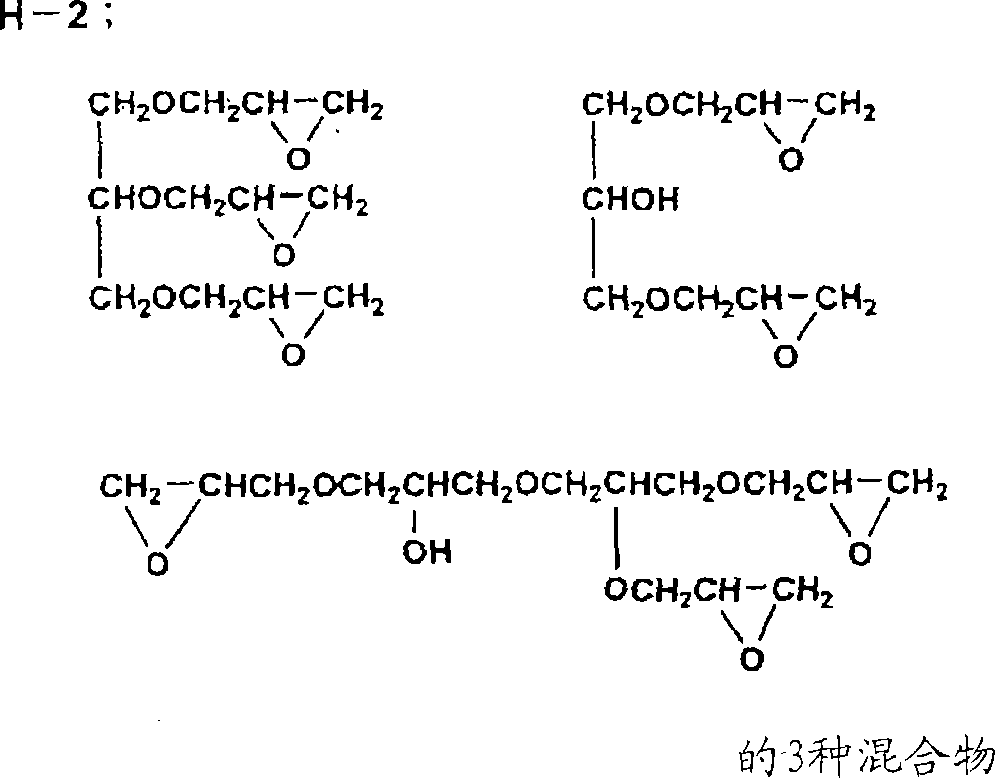

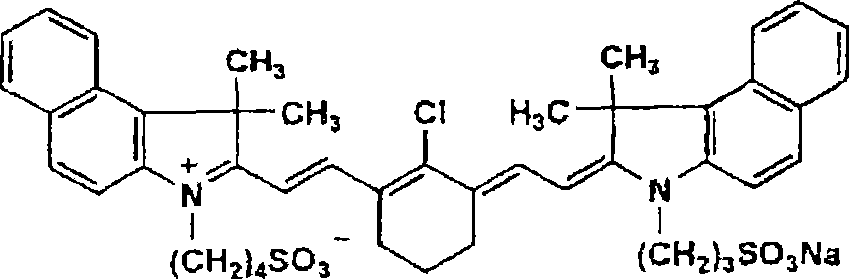

[0272] The composition of the coating liquid for thermal image forming layer (1) to (8) (solid content 8% by mass) (numbers without designated units in the table indicate parts by mass)

[0273] Table 2

[0274] ...

Embodiment 2

[0295] Example 2 (printing plate material)

[0296] Preparation of coating liquid for primer layer and hydrophilic layer

[0297] The materials in the table below were thoroughly mixed and stirred, and filtered to obtain an undercoat coating liquid having a solid content of 20% by mass.

[0298] Composition of the primer coating liquid (solid content 20% by mass) (Numerical values without units listed in the table indicate parts by mass)

[0299] Table 4

[0300] Material

Bottom layer

Colloidal silica (alkaline type): Sinuotex (Sune-Tex)-XS (manufactured by Nissan Chemical Co., Ltd., solid content 20% by mass)

50.00

Acrylic emulsion AE986A (manufactured by JSR, Tg2°C, solid content 35.5% by mass)

15.31

Carbon black pigment particles: SD9020 (manufactured by Dainippon Ink Co., Ltd., true specific gravity is about 2.0g / cm 3 , The primary particle size is below 100nm, the solid content is 30 mass

%) Water dispersion

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com