Multiple-package curable coating material composition, method for forming coating film, and coated article

A curing type and composition technology, applied to the surface coating liquid device, polyurea/polyurethane coating, coating, etc., can solve the problem of poor adhesion, processability, poor physical properties of the coating film, processability, and recoating Solve problems such as poor appearance of permanent coating film, hinder siloxane crosslinking reaction, etc., and achieve the effects of excellent non-adhesiveness, excellent chemical resistance, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] The present invention will be described below based on examples, but the present invention is not limited thereto.

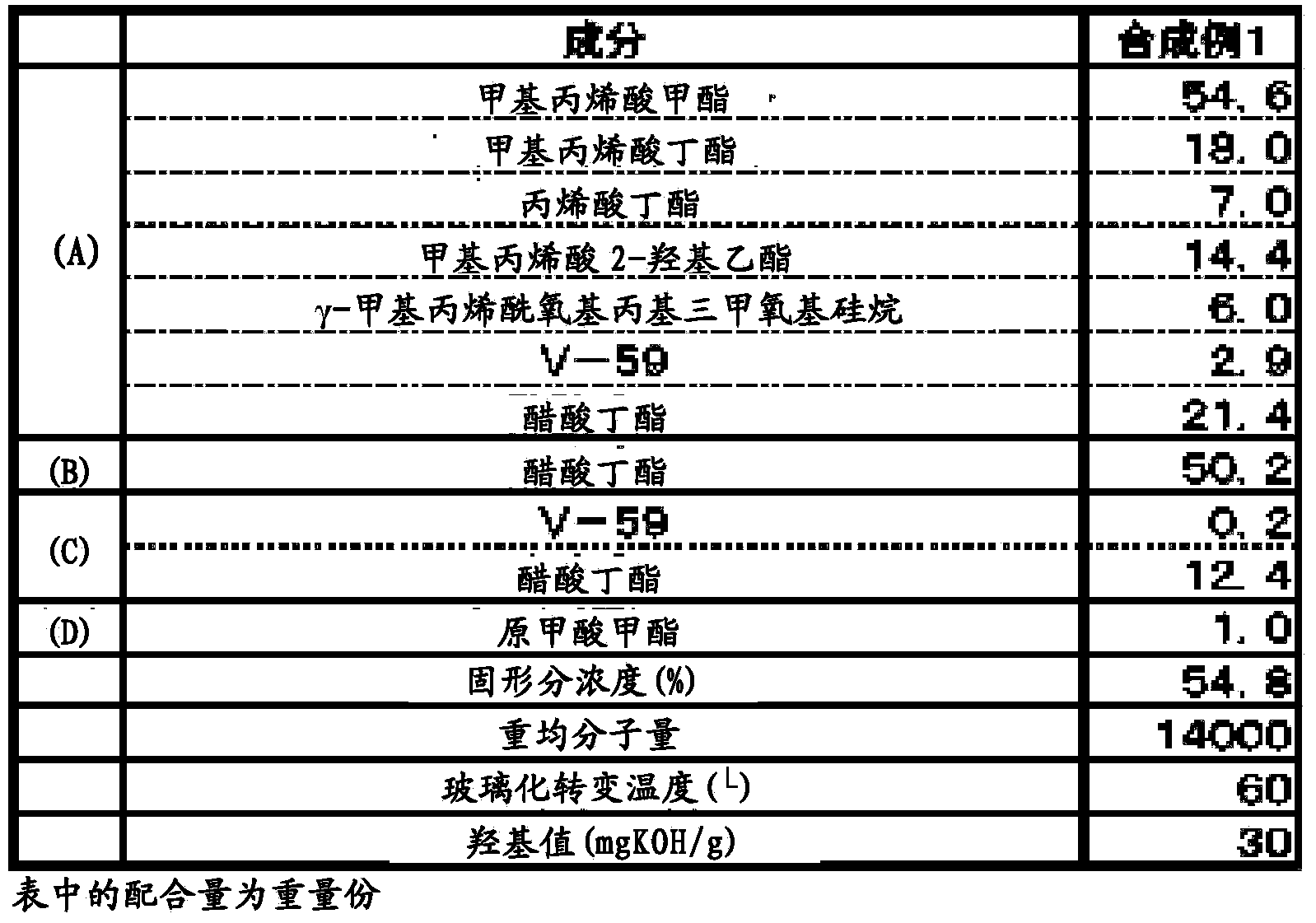

Synthetic example 1

[0105] (Synthesis Example 1: Synthesis of Vinyl Copolymer (A) Having a Hydroxyl Group)

[0106] Put the component (B) shown in Table 1 in a container equipped with a stirrer, a reflux cooler, a nitrogen gas introduction tube, and a dropping funnel, and after raising the temperature to 110°C while introducing nitrogen gas, add the component (A) in Table 1 The mixture was added dropwise from the dropping funnel at constant speed for 5 hours. Next, the liquid mixture of (C)component was dripped at a constant speed over 1 hour. Then, after stirring at 110 degreeC for 2 hours, it cooled to room temperature. Finally, the (D) component of Table 1 was added and stirred.

[0107] [Table 1]

[0108]

[0109] V-59: Manufactured by Wako Pure Chemical Industries, Ltd., 2,2'-azobis(2-methylbutyronitrile) (combination examples 1 to 8: preparation of curing agent)

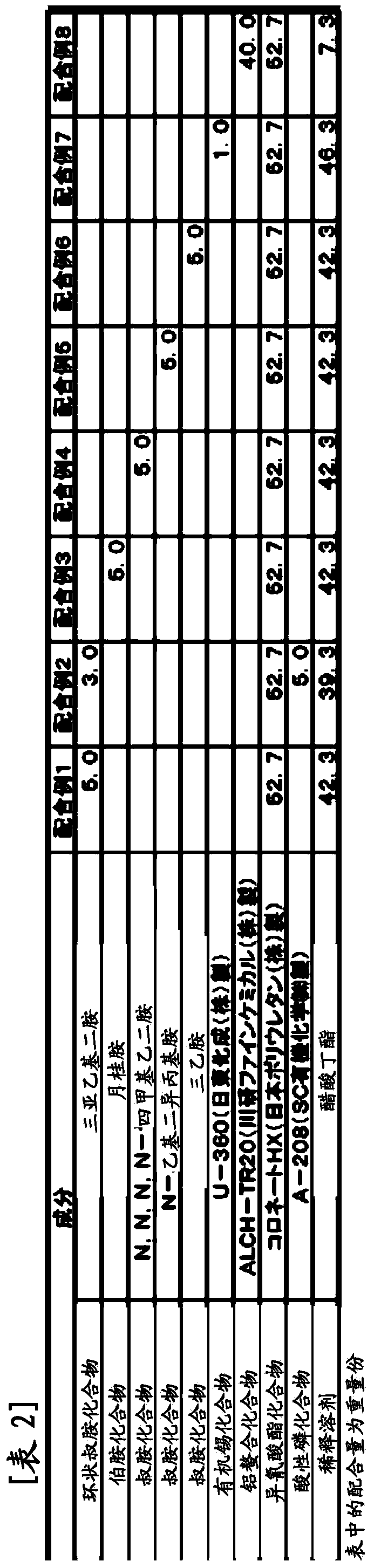

[0110] Prepare a curing agent according to the formulation shown in Table 2.

[0111] In compounding example 3 and compo...

Embodiment 1~4

[0113] (Examples 1-4, Comparative Examples 1-10)

[0114] When coating, prepare a coating solution according to the formulations shown in Table 3 and Table 4, and apply it to ABS resin molded boards and polycarbonate molded boards by air jet coating method so that the dry film thickness becomes 10 to 15 μm. It dried at 80 degreeC for 30 minutes, the coating film was formed, and the evaluation of the coating film was performed by the following method.

[0115]

[0116] (Evaluation of coating film)

[0117] With respect to the coating films formed in Examples 1 to 4 and Comparative Examples 1 to 10, ethanol rubbing resistance, non-tackiness, bendability, substrate adhesion, and appearance were evaluated. Among them, ethanol rubbing resistance, non-adhesiveness, bendability, and appearance were evaluated with ABS resin molded boards, and substrate adhesion was evaluated with polycarbonate molded boards. The results are shown in Table 5.

[0118] (Evaluation of ethanol rubbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com