Thick plate polyurethane primer and preparation method thereof

A technology of polyurethane primer and polyester resin, which is applied in the field of coatings, can solve the problems of poor performance of the primer, and achieve the effects of high salt spray resistance, good flexibility and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

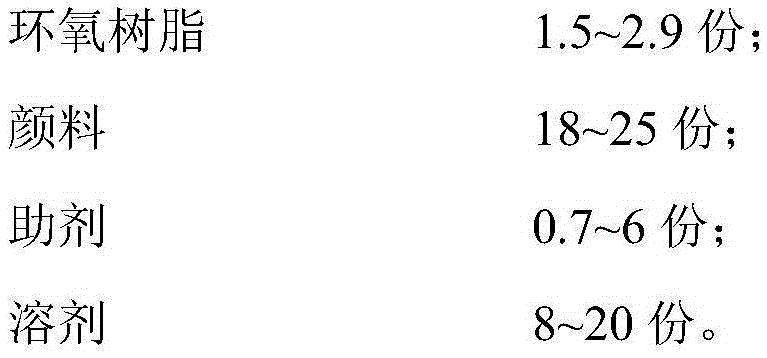

Method used

Image

Examples

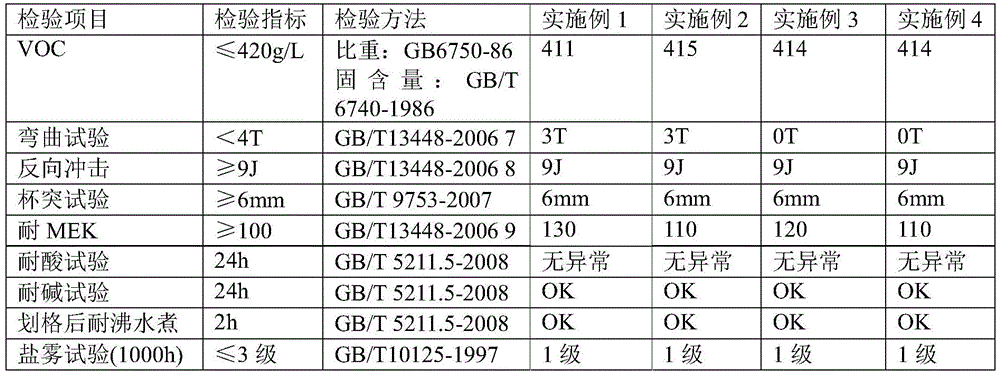

Embodiment 1

[0055] A preparation method for thick plate polyurethane primer, comprising the following steps:

[0056]1) Mix 20 parts of polyester resin SKYBONES42020 parts, pigment titanium dioxide R-99620 parts, 5 parts of barium sulfate PRECIPITATEDBARIUMSULFATE, anti-settling agent CAB-O-SILM-50.2 parts, add solvent S-100# aromatic hydrocarbon solvent 3 parts, isophorone 5 parts, ground to a fineness of no more than 15 μm to obtain a slurry; the polyester resin is a large molecular weight saturated polyester resin with a molecular weight of 16,000, a hydroxyl value of 4-8 mgKOH / g, and an acid value of 0-13 mgKOH / g. The use of high molecular weight linear or partially branched polyester resin can ensure high flexibility, processability and adhesion of the coating. If the hydroxyl value of the polyester resin is too high, the reactive groups cannot react completely, which will affect the water resistance of the film; if the hydroxyl value is too low, the reactive groups will be insuffici...

Embodiment 2

[0063] A preparation method for thick plate polyurethane primer, comprising the following steps:

[0064] 1) 17 parts of polyester resin SKYBONES42019 parts of pigment titanium dioxide R-99619 parts, barium sulfate PRECIPITATEDBARIUMSULFATE 5 parts, anti-settling agent CAB-O-SILM-50.2 parts, solvent S-100# aromatic hydrocarbon solvent 2 parts, isophorone 4 parts , mixed, and ground to a fineness of not more than 15 μm to obtain a slurry; the polyester resin has a molecular weight of 16,000, a hydroxyl value of 4-8 mgKOH / g, and an acid value of 0-13 mgKOH / g.

[0065] 2) Add SKYBONES4208 parts of polyester resin, 4 parts of isocyanate DESMODUR3175SN and 1 part of organic tin catalyst DBTL to the slurry; add 36 parts of amino resin YP56036 parts, acid catalyst CATALYST60000.4 parts, epoxy resin EPIKOTE828EL2.9 parts, leveling and defoaming 1 part of EFKA36000 part, 0.8 part of adhesion promoter TZ-8805, add 2 parts of solvent S-100# aromatic hydrocarbon solvent, 3 parts of isopho...

Embodiment 3

[0069] A preparation method for thick plate polyurethane primer, comprising the following steps:

[0070] 1) Take 14 parts of polyester resin SKYBONES42014 parts, pigment titanium dioxide R-99614 parts, barium sulfate PRECIPITATEDBARIUMSULFATE 5 parts, anti-settling agent CAB-O-SILM-50.2 parts, solvent S-100# aromatic hydrocarbon solvent 3 parts, isophorone 5 parts , mixed, and ground to a fineness of not more than 15 μm to obtain a slurry; the polyester resin has a molecular weight of 16,000, a hydroxyl value of 4-8 mgKOH / g, and an acid value of 0-13 mgKOH / g.

[0071] 2) Add 4204 parts of polyester resin SKYBONES, 3 parts of isocyanate DESMODUR3175SN, 1 part of organic tin catalyst DBTL, and mix them; add 32 parts of amino resin YP56032, acid catalyst CATALYST60000.4 parts, epoxy resin EPIKOTE828EL1.6 parts, leveling agent Foam agent EFKA36001 part, adhesion promoter TZ-88050.8 part, add solvent S-100# aromatic hydrocarbon solvent 2 parts, isophorone 3 parts, cyclohexanone 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com