Powder blending technology of PVC reinforcing agent and sealed powder blending machine

A kind of enhancer, fully sealed technology, applied in the chemical field, can solve the problems of air and dust flying in the exhaust hole, material moisture evaporation, environmental protection failure, etc., to achieve the effect of saving electric energy, reducing the volatilization of components, energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

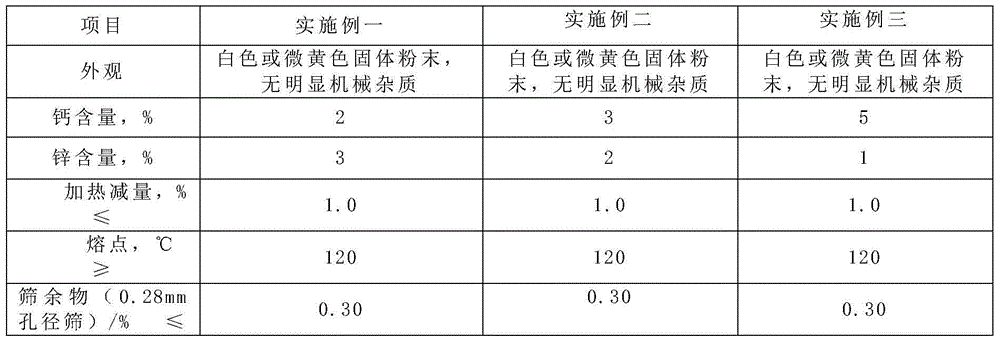

Embodiment 1

[0039] The powder mixing process of this PVC reinforcing agent, its steps are as follows:

[0040] a, prepare raw materials, the mass parts of each raw material component are respectively:

[0041] Hydrotalcite 8 parts

[0042] 3 parts zinc stearate

[0043] 2 parts calcium stearate

[0044] Lubricant 34 parts

[0045] Calcium carbonate 15 parts

[0046] b. Mix the above ingredients according to their respective parts by mass, add them into a fully sealed powder mixer, and stir for 40 minutes at 25°C. The internal rotation of the fully sealed powder mixer is 400 rpm, and the external rotation is 7 rpm. / min;

[0047] c. Take it out from the fully sealed powder mixer and pack it.

[0048] Specifically, in step a, the lubricant is paraffin. In step b, the power of the internally rotating main motor 6 is 11KW, and the power of the externally rotating auxiliary motor 8 is 7.5KW.

Embodiment 2

[0050] The powder mixing process of this PVC reinforcing agent, its steps are as follows:

[0051] a, prepare raw materials, the mass parts of each raw material component are respectively:

[0052] Hydrotalcite 8.5 parts

[0054] Calcium stearate 2.5 parts

[0055] Lubricant 37 parts

[0056] Calcium carbonate 17 parts

[0057] b. Mix the above ingredients according to their respective mass parts, add them into the fully sealed powder mixer, and stir for 45 minutes at 30°C. The internal rotation of the fully sealed powder mixer is 420 rpm, and the external rotation is 10 rpm. / min;

[0058]c. Take it out from the fully sealed powder mixer and pack it.

[0059] Specifically, in step a, the lubricant is stearic acid. In step b, the power of the internally rotating main motor 6 is 11KW, and the power of the externally rotating auxiliary motor 8 is 7.5KW.

Embodiment 3

[0061] The powder mixing process of this PVC reinforcing agent, its steps are as follows:

[0062] a, prepare raw materials, the mass parts of each raw material component are respectively:

[0063] Hydrotalcite 10 parts

[0064] Zinc stearate 5 parts

[0065] 3 parts calcium stearate

[0066] Lubricant 40 parts

[0067] Calcium carbonate 20 parts

[0068] b. Mix the above ingredients according to their respective parts by mass, add them into a fully sealed powder mixer, and stir for 50 minutes at 35°C. The internal rotation of the fully sealed powder mixer is 450 rpm, and the external rotation is 12 rpm. / min;

[0069] c. Take it out from the fully sealed powder mixer and pack it.

[0070] Specifically, in step a, the lubricant is monoglyceride. In step b, the power of the internally rotating main motor 6 is 11KW, and the power of the externally rotating auxiliary motor 8 is 7.5KW.

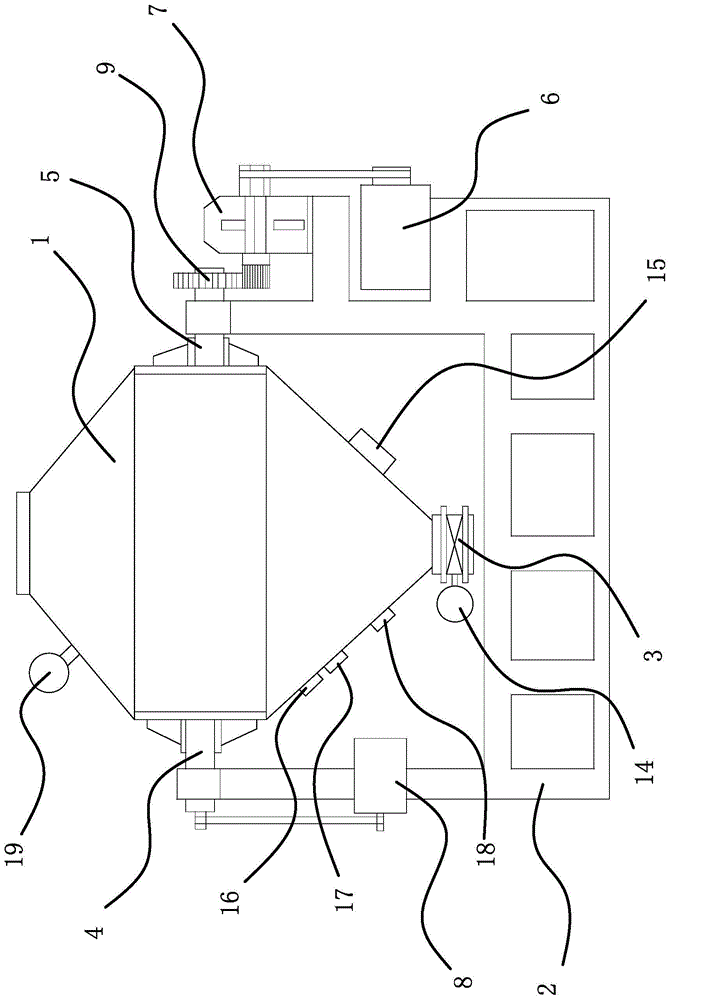

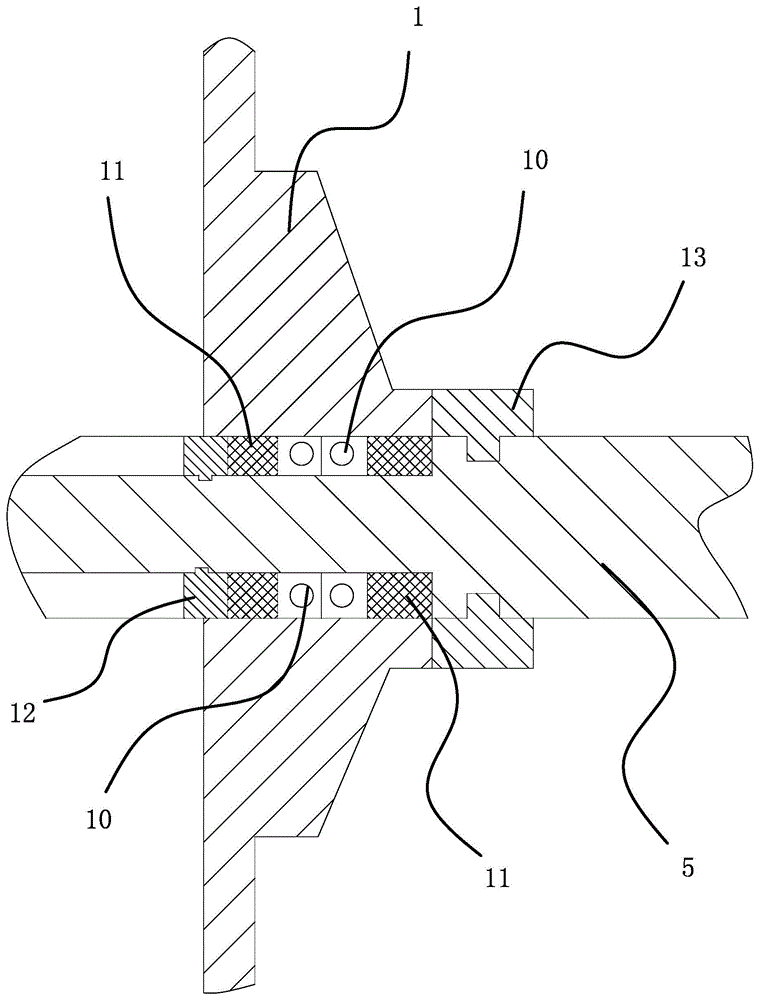

[0071] like figure 1 , figure 2 As shown, the present invention also discloses a fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com