Polycarbonate/polyester composition and preparation method thereof

A technology of polycarbonate and polycarbonate resin, which is applied in the field of composition and its preparation, can solve problems such as not being able to meet the requirements of use, and achieve the effects of improving nucleation efficiency, chemical resistance, and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

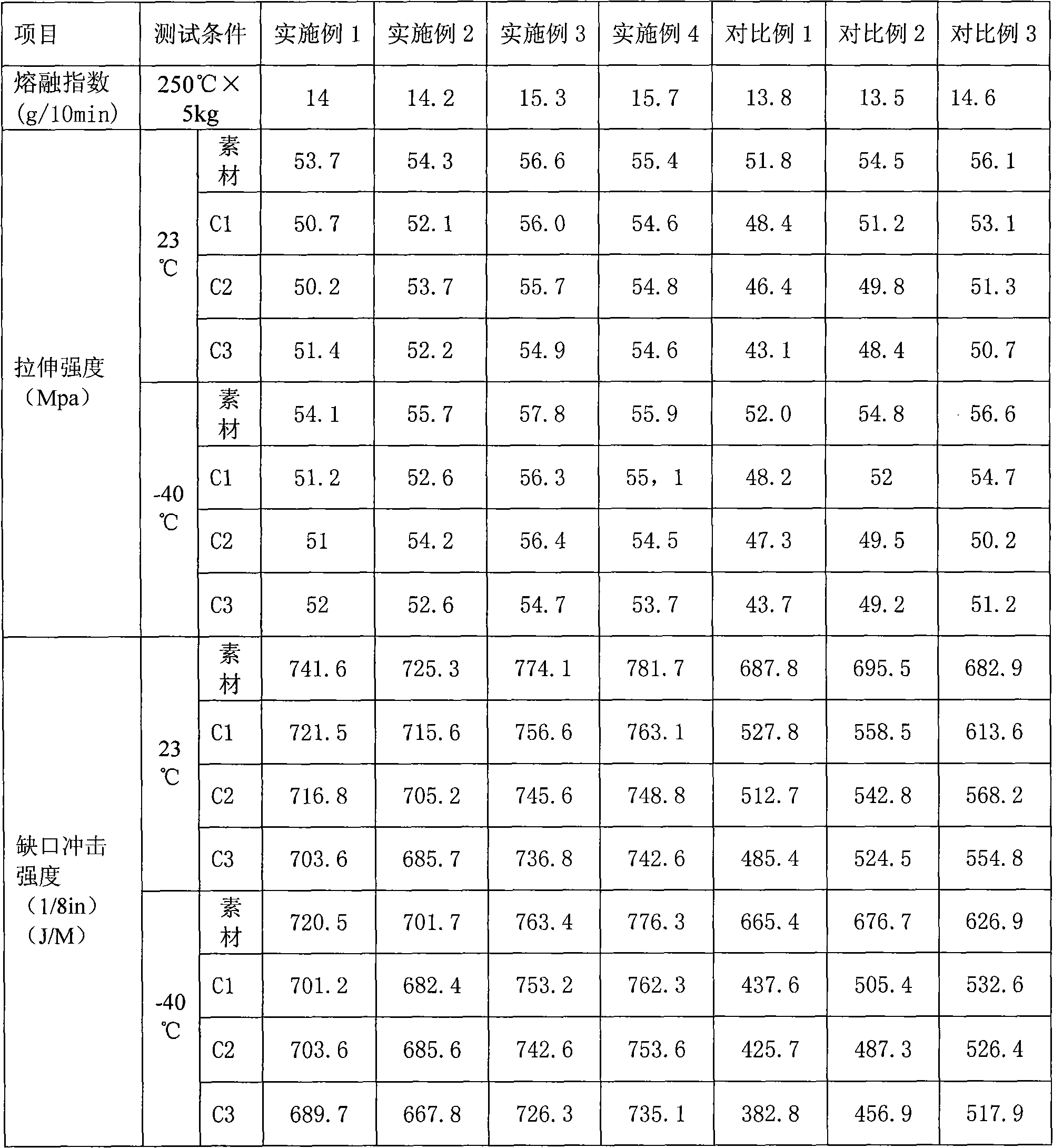

Examples

Embodiment 1

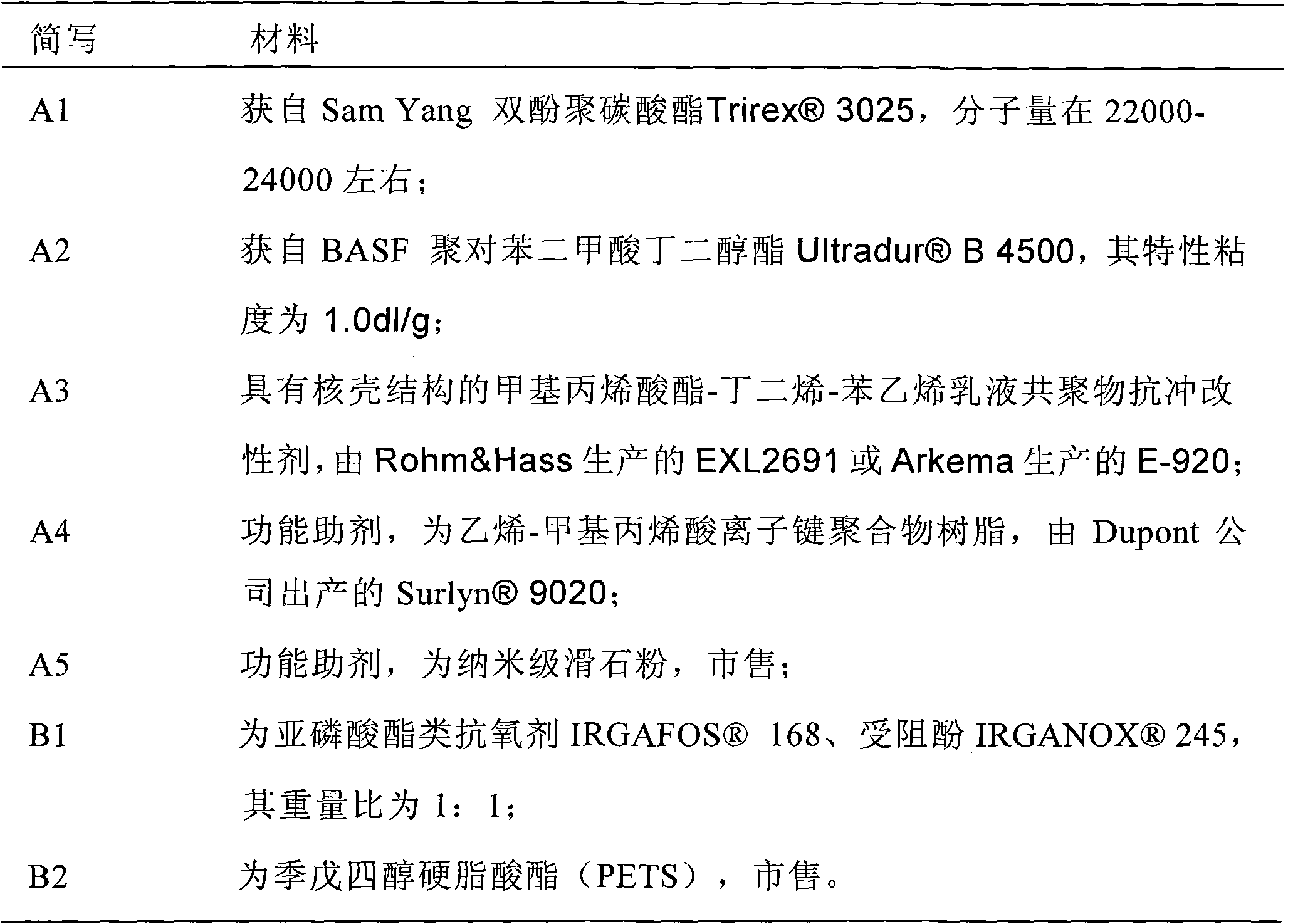

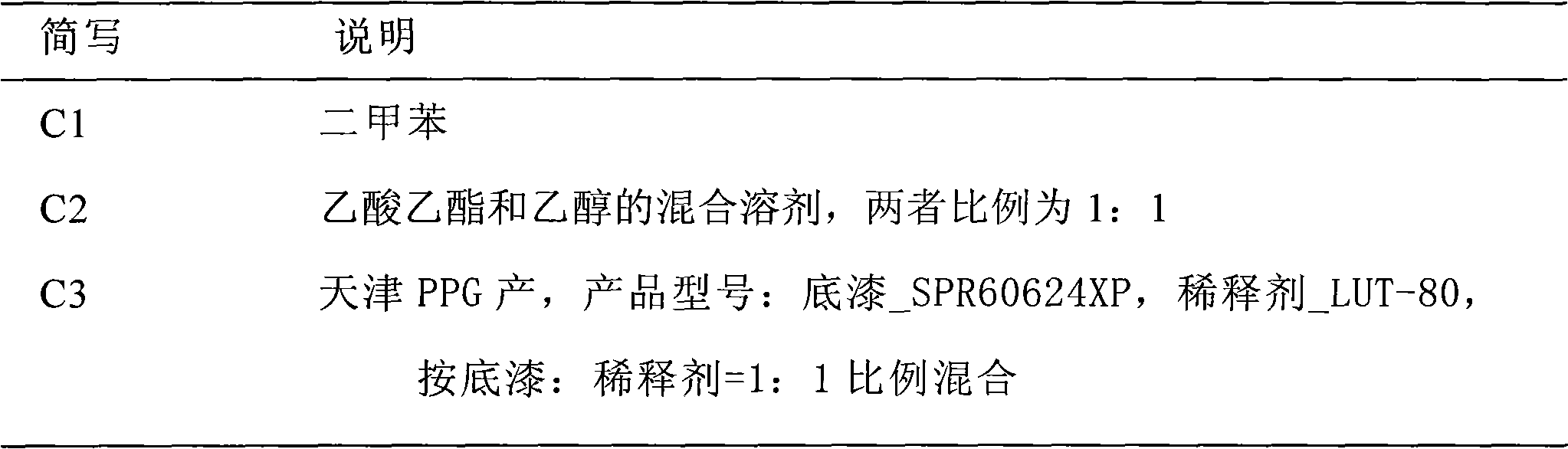

[0042] A method for preparing a polycarbonate / polyester composition with excellent chemical resistance, the method is a one-step method, comprising the following steps:

[0043] (1) Prepare materials according to the following components, each component is shown in Table 1: polycarbonate (PC), polybutylene terephthalate (PBT), toughening agent, functional auxiliary agent, antioxidant, Lubricant, the content of each component is as shown in table 2;

[0044] (2) Take all the components out of the high-mixer and then put them into the screw machine for extrusion and granulation. The screw machine speed is 300-500rpm and the temperature is 225-260°C to obtain the product.

Embodiment 2-4

[0046] A method for preparing a polycarbonate / polyester composition with excellent chemical resistance, the method is a masterbatch method, comprising the following steps:

[0047] (1) Prepare materials according to the following components, each component is shown in Table 1: polycarbonate (PC), polybutylene terephthalate (PBT), toughening agent, functional auxiliary agent, antioxidant, Lubricant, the content of each component is as shown in table 2;

[0048] (2) After pre-mixing polybutylene terephthalate (PBT) and functional additives in a high-mixer in proportion, put them into a screw machine to extrude and granulate to obtain functional masterbatches. The rotation speed is 300-500rpm, and the temperature is 225-255°C;

[0049] (3) The remaining components and nucleating masterbatch are fully mixed and exported from the high mixer, and then put into the screw machine to extrude and granulate. product.

Embodiment 5

[0076] A method for preparing a polycarbonate / polyester composition with excellent chemical resistance, the method comprising the steps of:

[0077] (1) Prepare materials according to the following components: 50kg polycarbonate (PC), 30kg polybutylene terephthalate (PBT), 5kg ethylene-vinyl acetate copolymer-functionalized maleic anhydride as chemical toughening modification Agent, 1kg ionomer resin as functional additive, 0.1kg tetrakis [β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionate] pentaerythritol ester as antioxidant, 0.1kg lubricant N, N'-ethylene bis stearic acid amide, wherein the polycarbonate resin is an aromatic polycarbonate resin, and the aromatic polycarbonate resin is passed through 1,1-bis(4-hydroxyphenyl)ethane and diphenyl carbonate The ester is obtained by polycondensation reaction, the molecular weight is 30,000, the glass transition temperature is 150°C, and the relative density of polybutylene terephthalate is 1.29-1.35g / cm 3 , the intrinsic viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com