High-stability composite coating

A composite coating with high stability technology, applied in the direction of coating, etc., can solve the problems of shortening product shelf life, affecting coating performance, easy cracking, etc., and achieves excellent chemical resistance, excellent adhesion, and long shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

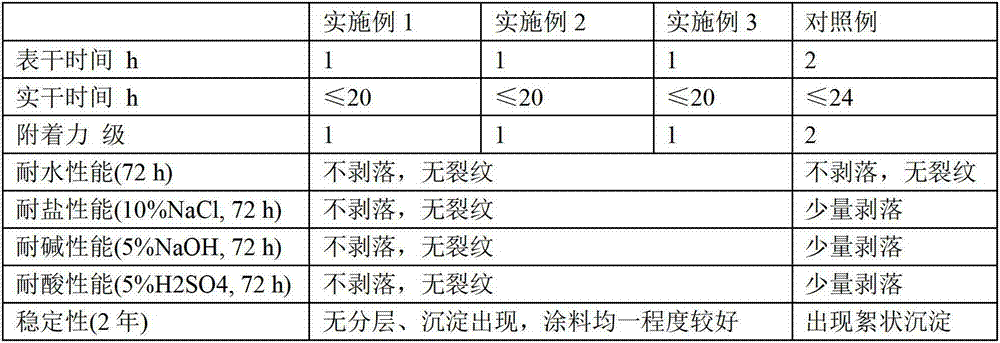

Examples

Embodiment Construction

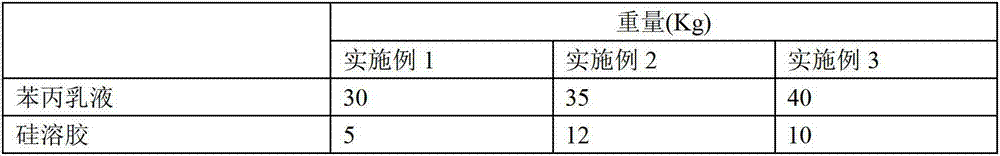

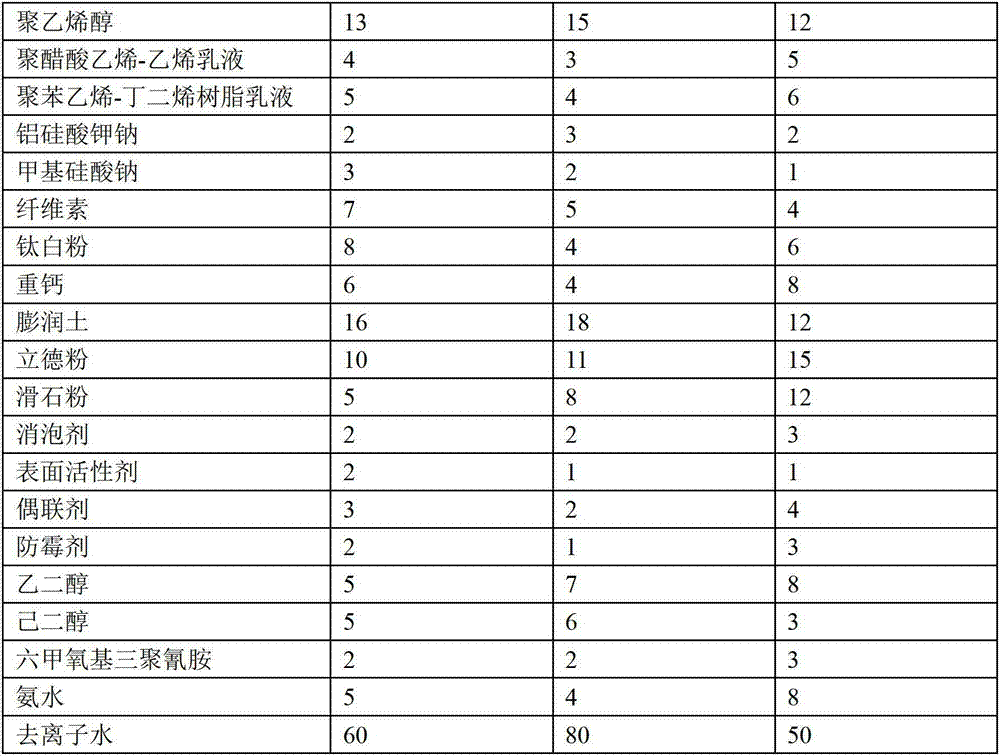

[0018] The components were prepared in the weight ratios shown in Table 1.

[0019] The weight proportion of table 1 embodiment 1~embodiment 3

[0020]

[0021]

[0022] In the above-mentioned examples, the solid content range of the styrene-acrylic emulsion is controlled between 45% and 50%; the solid content range of the silica sol is between 20% and 30%; the defoamer uses tributyl phosphate; the surfactant is ten Sodium dialkyl sulfonate; silane coupling agent KH-570 is used as the coupling agent; The preparation method is:

[0023] S1: Polyvinyl alcohol, potassium sodium aluminosilicate, sodium methyl silicate, cellulose, titanium dioxide, heavy calcium, bentonite, lithopone, talcum powder, defoamer, surfactant, coupling agent, anti-foaming agent Mold agent, ethylene glycol, hexylene glycol, hexamethoxymelamine, and water are mixed evenly in proportion, and then ground;

[0024] S2: Add styrene-acrylic emulsion, polyvinyl acetate-ethylene emulsion, polystyrene-but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com